Blistering and packaging machine

A plastic packaging and top molding technology, which is applied in the field of packaging machines, can solve the problems of changing the molding effect, module damage, plastic scrapping, etc., and achieve the effect of good molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

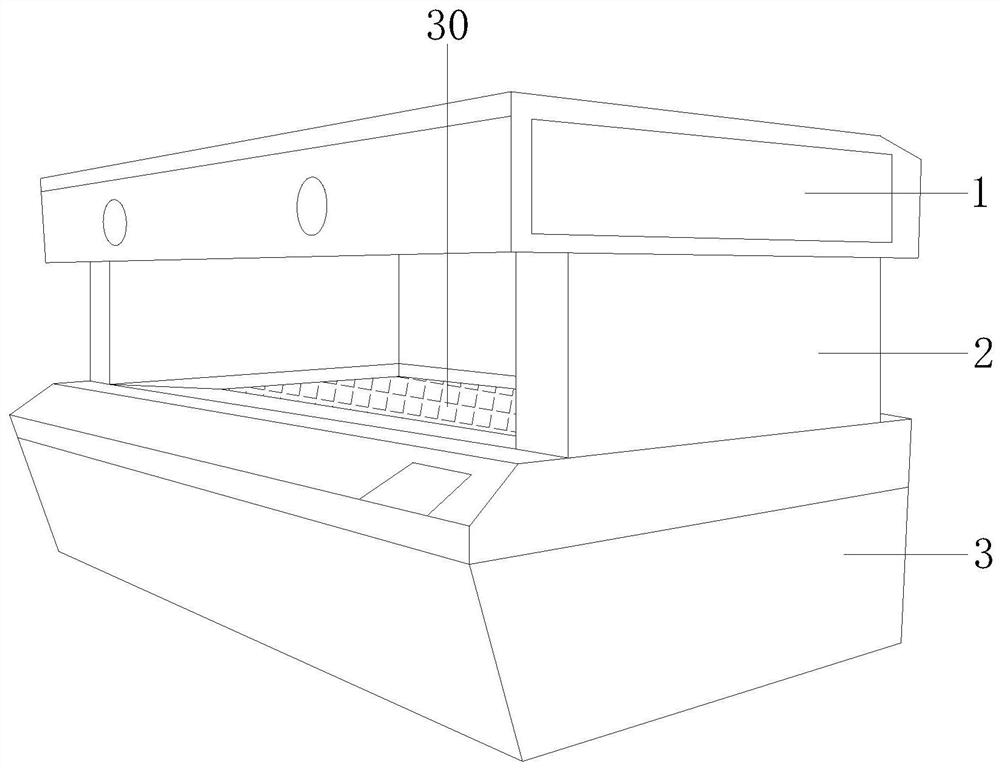

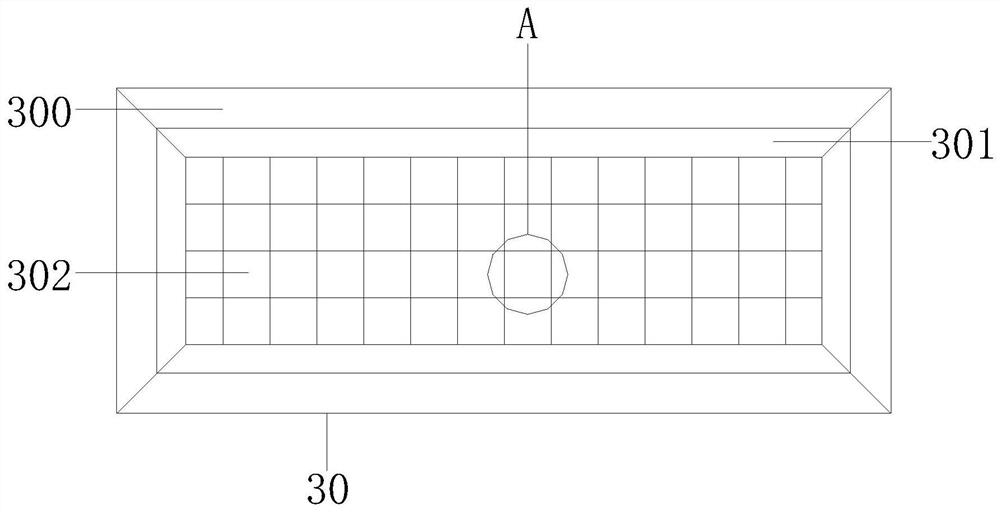

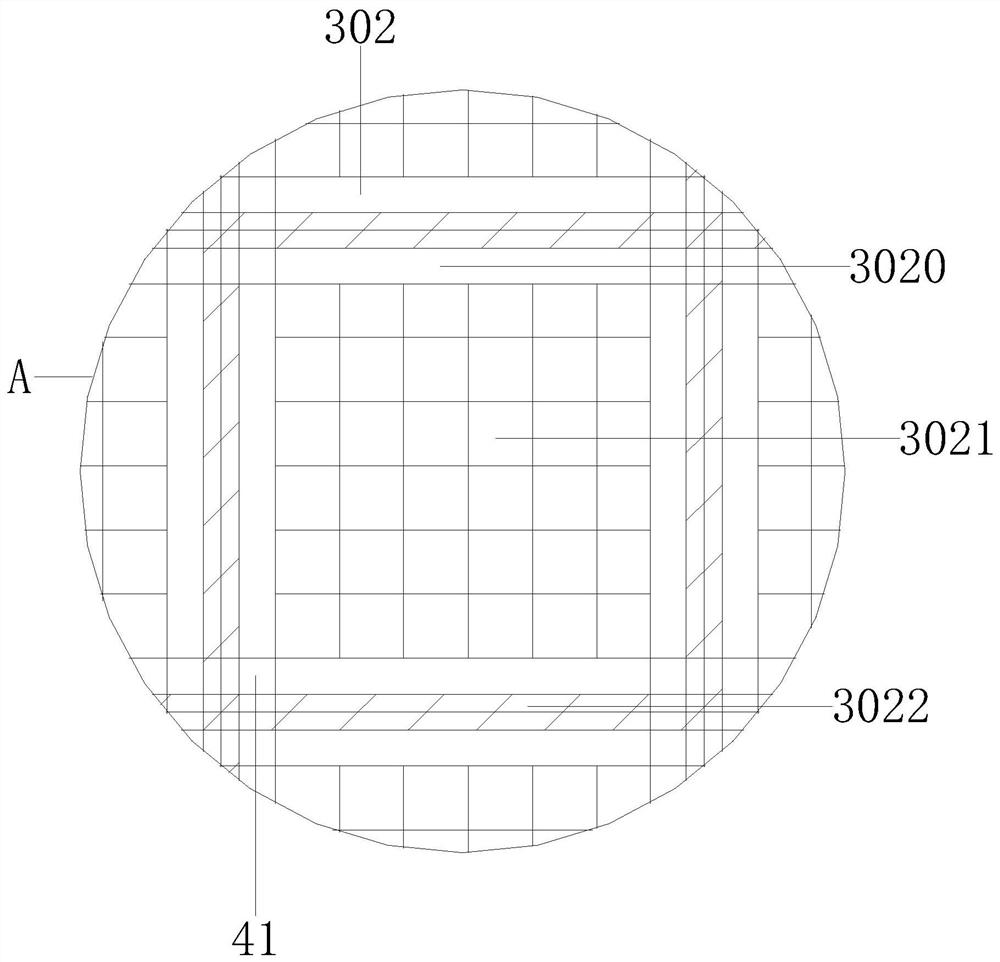

[0027] Example 1 see Figure 1-6 , the present invention provides a technical solution for a blister packaging machine: its structure includes a top molding machine 1, a lifting frame 2, and a bottom plastic seat 3, and the top molding machine 1, bottom plastic seat 3 are installed and connected to the lifting frame 2, and the The top molding machine 1 and the bottom plastic seat 3 are equipped with a type attachment plate 30, the type attachment plate 30 is composed of a frame 300, a movable main frame 301, and a grid plastic plate 302, and the frame 300 is used to fix the movable main frame 301 and the installation of the frame, the frame 300 is embedded with the movable main frame 301, and the movable main frame 301 is installed and connected with the compartment plastic plate 302, and the compartment plastic plate 302 includes a lifting structure 3020, a compartment 3021 , Embedded partitions 3022, the movable main frame 301 has the same structure as the lifting structure ...

Embodiment 2

[0029] Example 2 see Figure 7-8 , the present invention provides a technical solution of a blister packaging machine: the structure of the bottom plastic grid 401 includes a movable grid 4010, a lifting bracket 4011, and an internal support 4012, and the function of the internal support 4012 is to assist the movable grid 4010 Deformation plays an auxiliary support role. The movable grid 4010 is installed and connected with the lifting bracket 4011 and the inner support 4012. The movable grid 4010 is provided with a movable block 80, and the lifting bracket 4011 is equipped with a pole shaft 81. The material twister 60 includes a twist belt 600, an internal material shifter 601, a storage bag 602, and a rotator 603. The internal material shifter 601 is used to drive the storage bag 602 up and down to change the storage space of the storage bag 602 , it is convenient for the debris falling into the storage bag 602 to be moved out through the internal material shifter 601 so as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com