Large stepped incinerator grate overhauling and hoisting device and method

A lifting device and a stepped technology, which is applied in the field of lifting devices for inspection and maintenance of large-scale stepped incinerator grate, can solve the problems of inconvenient inspection and maintenance of flipped cover plates, high risk factor for hoisting, and increased maintenance time, so as to improve lifting efficiency and reduce The effect of hoisting risk factor and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

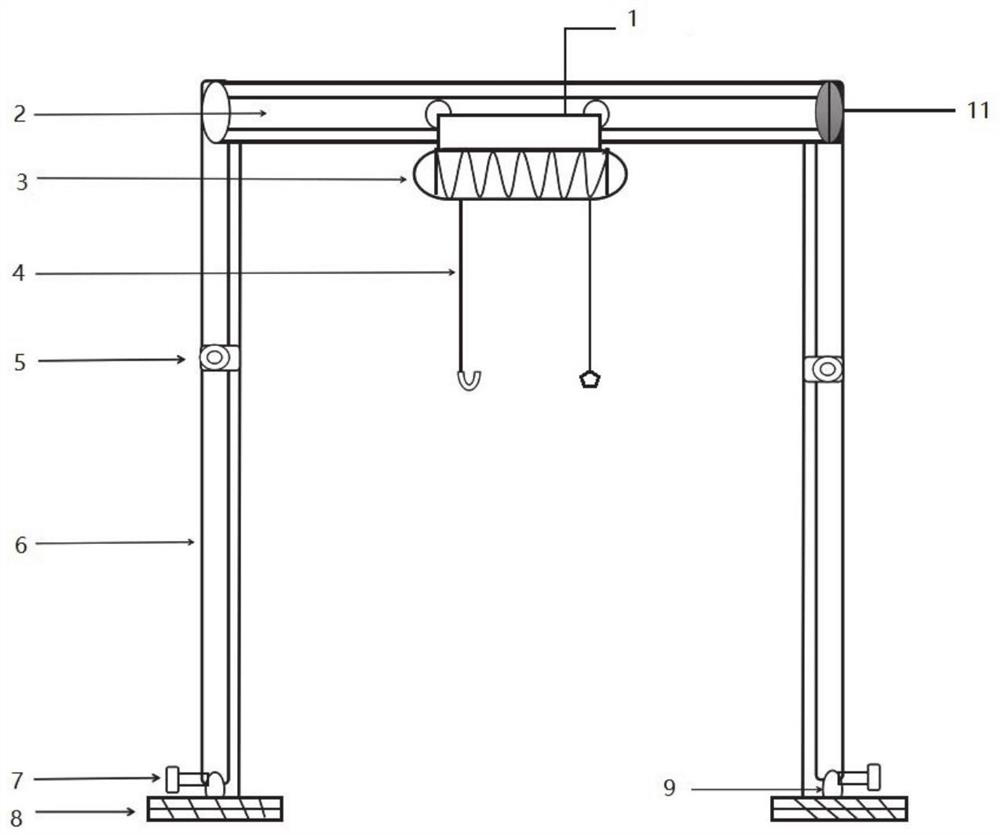

[0021] like figure 1 As shown, the present disclosure provides a large-scale stepped incinerator grate maintenance lifting device, including a support frame, a slide rail connected with the support frame and an adjustable anti-skid base, and a lifting mechanism connected with the slide rail; the adjustable anti-skid base includes The rotating wheels and the non-slip bottom plate are connected with each other, and the bottom end of the supporting frame is connected with the rotating wheels through a fixing piece.

[0022] Further, the support frame includes at least two sets of support rod groups, each set of support rod groups includes two support rod telescopic tubes arranged symmetrically, the two support rod telescopic tubes are connected by fixed tie rods, and the two ends of the fixed tie rods are respectively fixed on two One end of the slide rail is connected to the top of one set of support rods, and the other end is connected to the top of the other set of support rod...

Embodiment 2

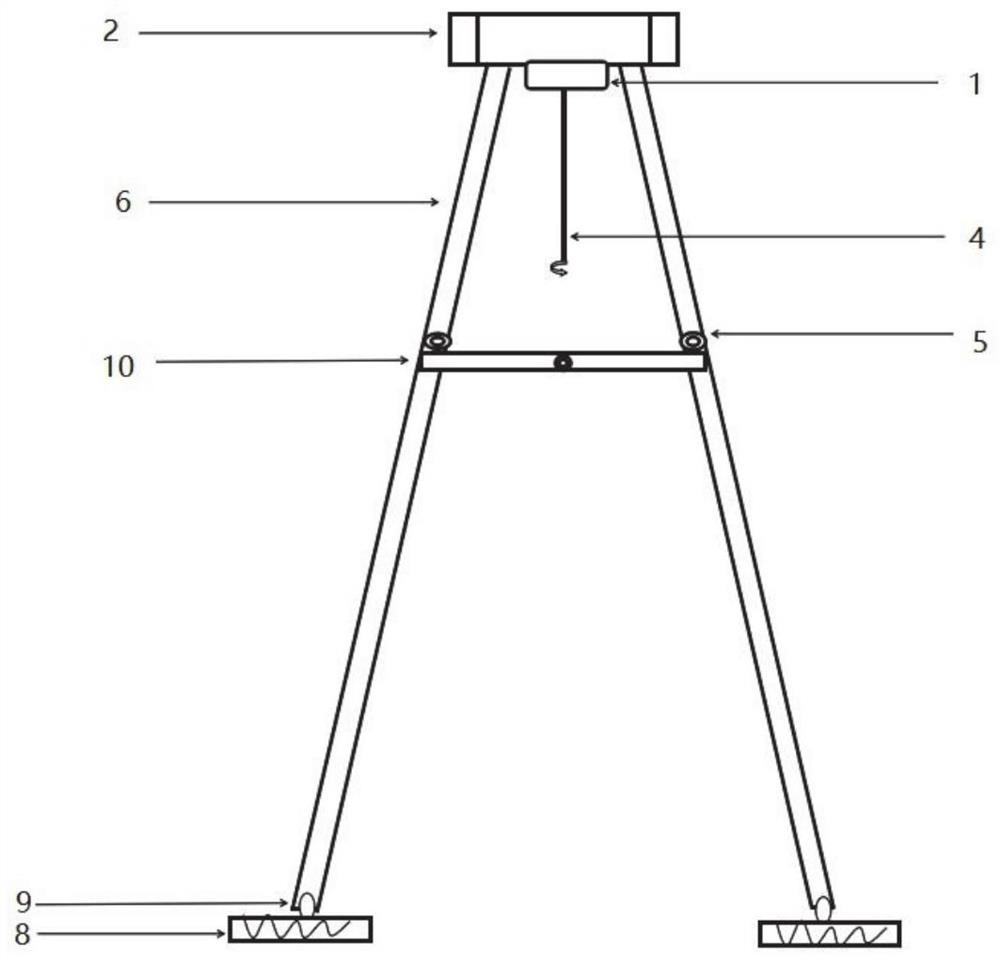

[0033] The disclosed device includes an electric lifting device, four supporting steel pipes, and a horizontal sliding track. One end of the supporting steel pipe and the horizontal sliding track is connected by an angle adjustment gear, and the supporting steel pipe can rotate around the horizontal sliding track; the lifting device is fixed on a horizontal In the sliding track, limit blocks are set at both ends; a fixed pull rod is set between two supporting steel pipes on one side, and the two ends of the pull rod are respectively fixed on the two supporting steel pipes, and the base of the supporting steel pipe is provided with a rotation angle wheel with a fixer And the corrugated feet can make it suitable for different heights and slopes and the support steel pipe is stable when it is supported by the "herringbone".

[0034] This kind of lifting device is used for hoisting the grate of the incinerator and the cover plate of the middle beam. In order to improve the lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com