Valve good in sealing performance

A sealing and good technology, applied in shaft sealing, valve details, valve devices, etc., can solve the problems of inability to achieve precise fit between valve stem and valve body, leakage, etc., to prevent slipping, increase cleanliness, facilitate maintenance and The effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

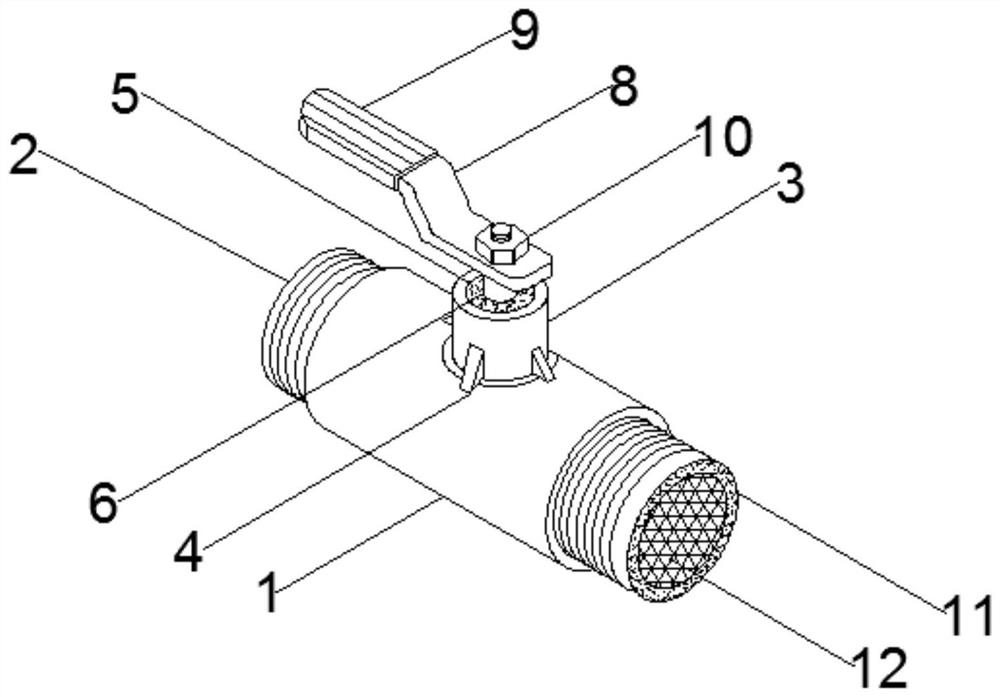

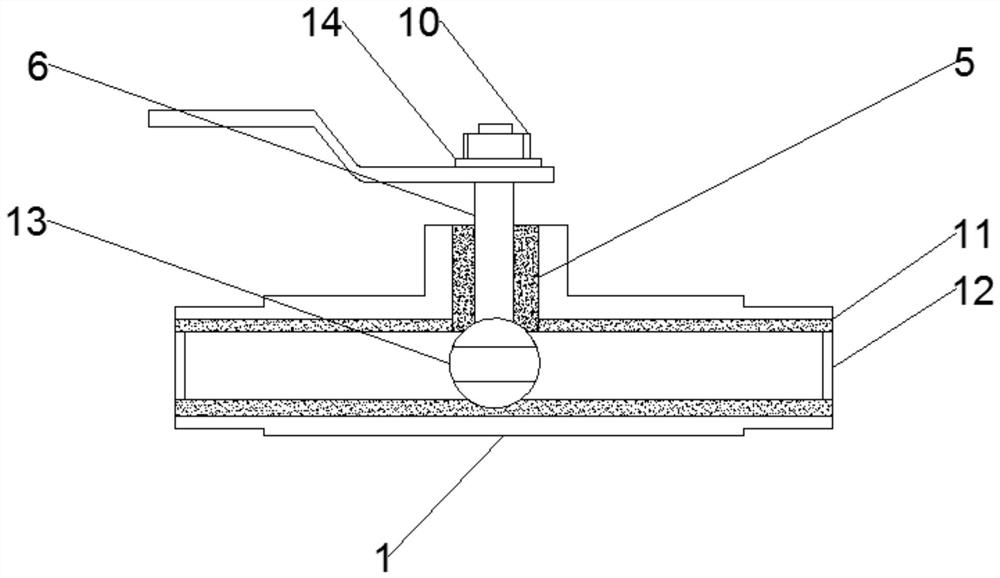

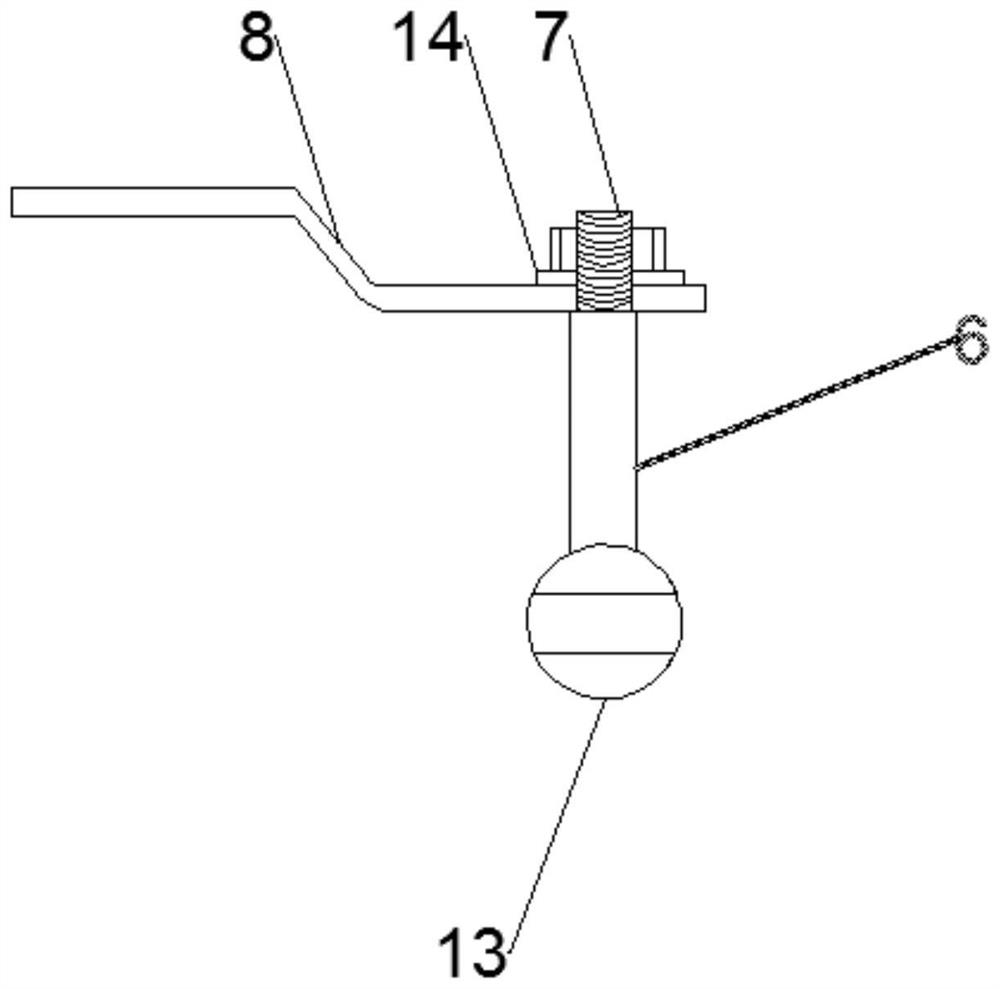

[0018] Example: as Figure 1-3 As shown in the figure, a valve with good sealing performance of the present invention includes a valve body 1, the two ends of the valve body 1 are provided with first threads 2, the top central end of the valve body 1 is fixedly connected with a rotating seat 3, and the bottom of the rotating seat 3 is fixedly connected with a rotating seat 3. A plurality of reinforcing ribs 4, the bottom of the reinforcing rib 4 is fixedly connected with the top of the valve body 1, the reinforcing rib 4 is a polyhedron structure with a side triangle and a front rectangle, the rotating seat 3 is a hollow cylindrical structure, and a rubber ring 5 is fixedly connected inside the rotating seat 3, The rubber ring 5 is a hollow cylindrical structure, a valve stem 6 is rotatably connected inside the rubber ring 5, a second thread 7 is provided on the top of the valve stem 6, a handle 8 is sleeved on the outer periphery of the second thread 7, and the surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com