A large field of view measurement method for surface topography of microspheres based on microscopic interferometry

A technology of micro-interference and surface topography, which is applied in the field of precision optical measurement engineering, can solve the problems of shallow depth of field and limit the effective measurement range of microscope imaging field of view, and achieve the goal of improving accuracy, increasing effective measurement range and improving measurement efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to describe the present invention more clearly and specifically, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

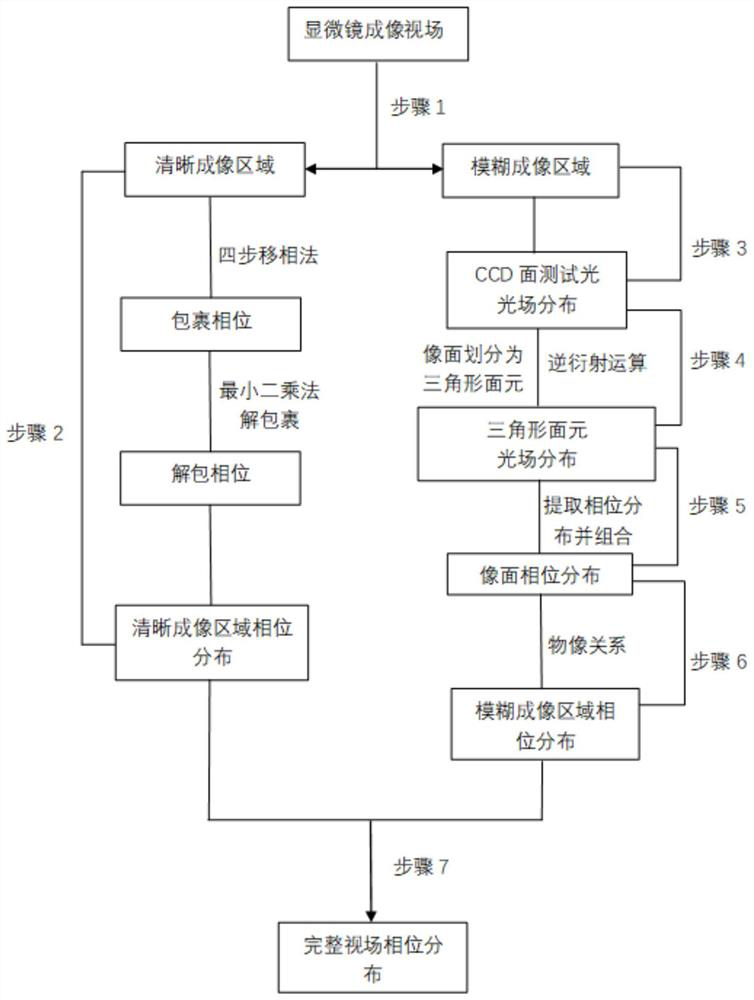

[0026] combine figure 1 , a large field of view measurement method for microsphere surface topography based on microscopic interference, the steps are as follows:

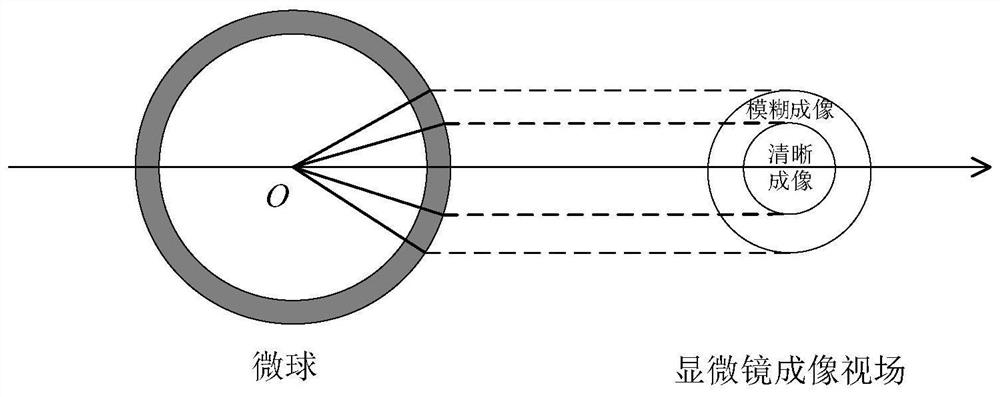

[0027] Step 1. Build a microscopic interference system to image the surface of the microsphere, and use the CCD to collect four phase-shifted interference fringe images I 1 , I 2 , I 3 , I 4 , according to the depth of field D of the microscopic interferometry system dof , divide the collected four phase-shifted interference fringe images into two regions: a clear imaging region where the central field of view is within the depth of field and a blurred imaging region where the peripheral field of view is outside the depth of field.

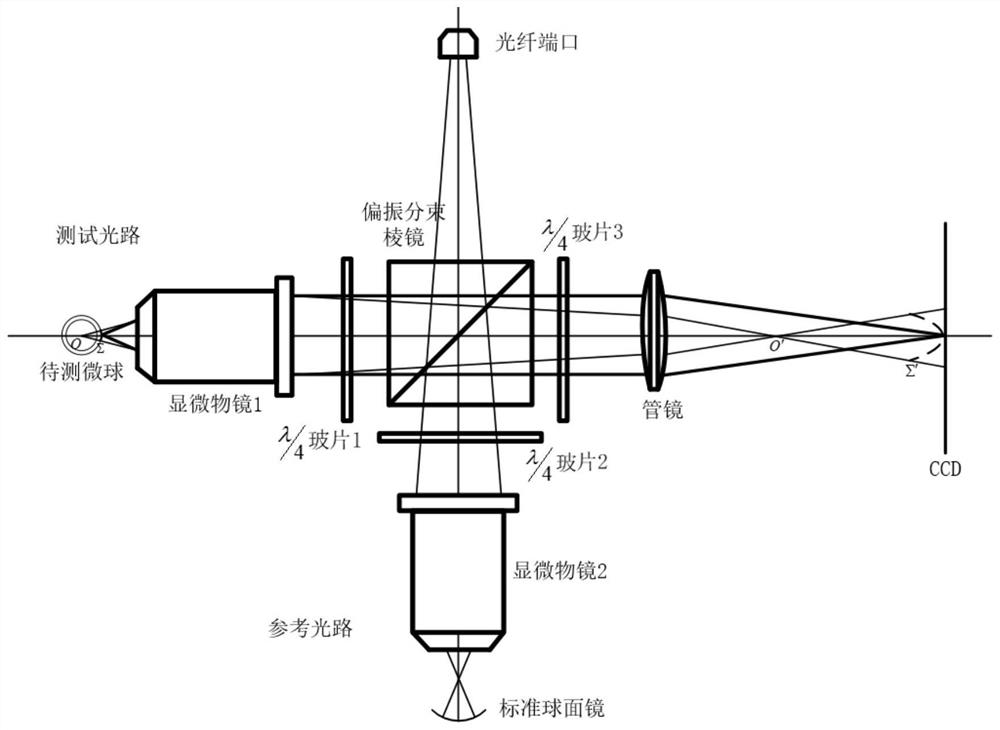

[0028] combine figure 2 , a schematic diagram of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com