Metal baseband surface defect dynamic monitoring device and detection method

A metal baseband and surface detection technology, applied in the direction of optical testing flaws/defects, etc., can solve problems such as inability to classify products, and achieve the effects of convenient organization and storage, real-time monitoring, and real-time result feedback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

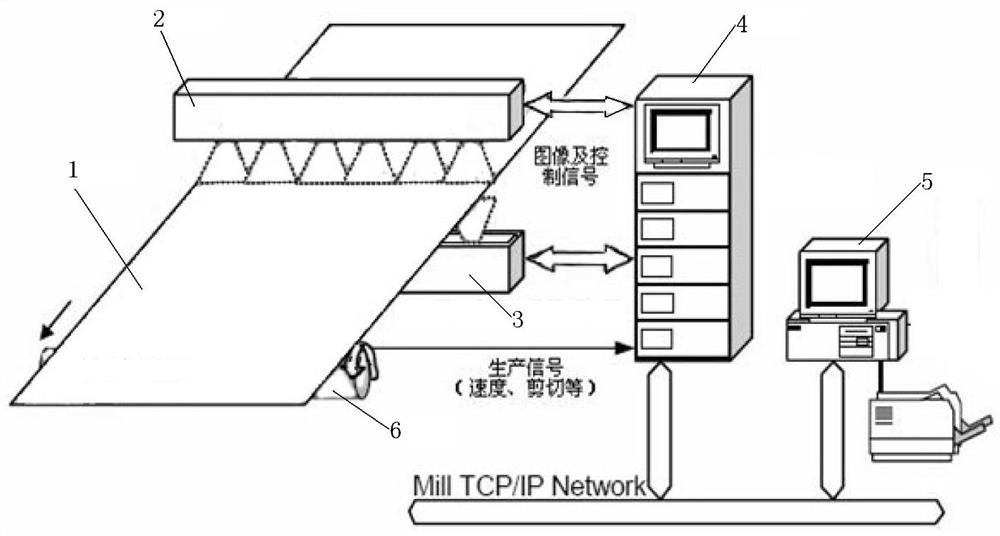

[0018] refer to figure 1 , a dynamic monitoring device for surface defects of a coated conductor metal base band, comprising a production line winding device 6, an upper surface detection bridge and an illumination device 2 are arranged above the metal base band 1, and a lower surface detection bridge and a lighting device 2 are provided below the metal base band 1 The lighting device 3, the production line winding device 6, the upper surface detection bridge and lighting device 2, the lower surface detection bridge and the lighting device 3 respectively transmit the production signal, image and control signal to the computer system 4 through the cable, and the computer system 4 conducts online analysis The various features of the product surface image realize the positioning, detection and measurement of surface defects, and then transmit the data to the alarm monitoring computer 5 through the network, and output various immediate and delayed signals.

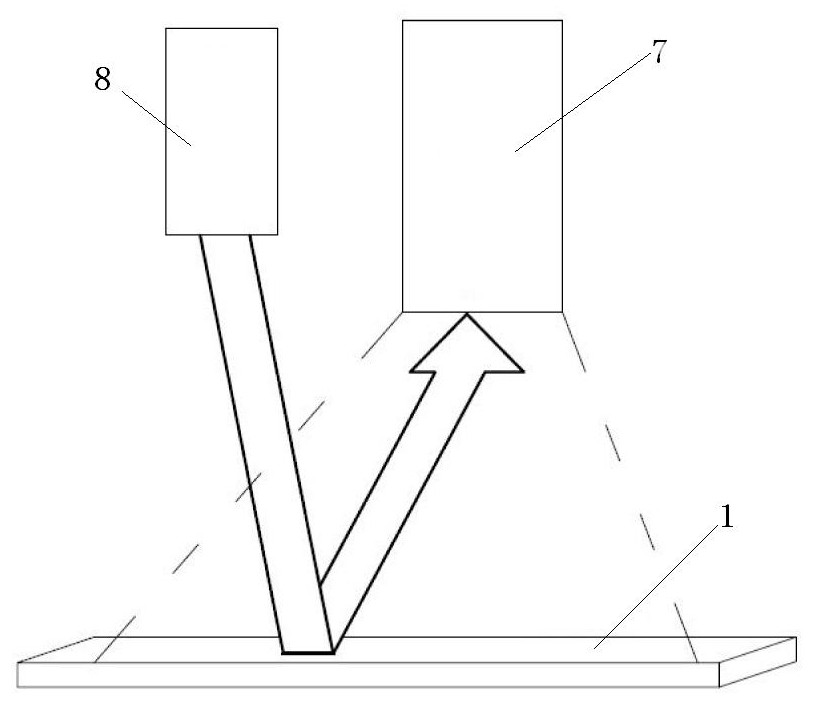

[0019] refer to figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com