Novel high-performance transformer

A transformer, high-performance technology, applied in transformer/inductor cooling, transformer/reactor installation/support/suspension, spring/shock absorber, etc. problems, to solve the fixed instability, reduce maintenance costs, and extend the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

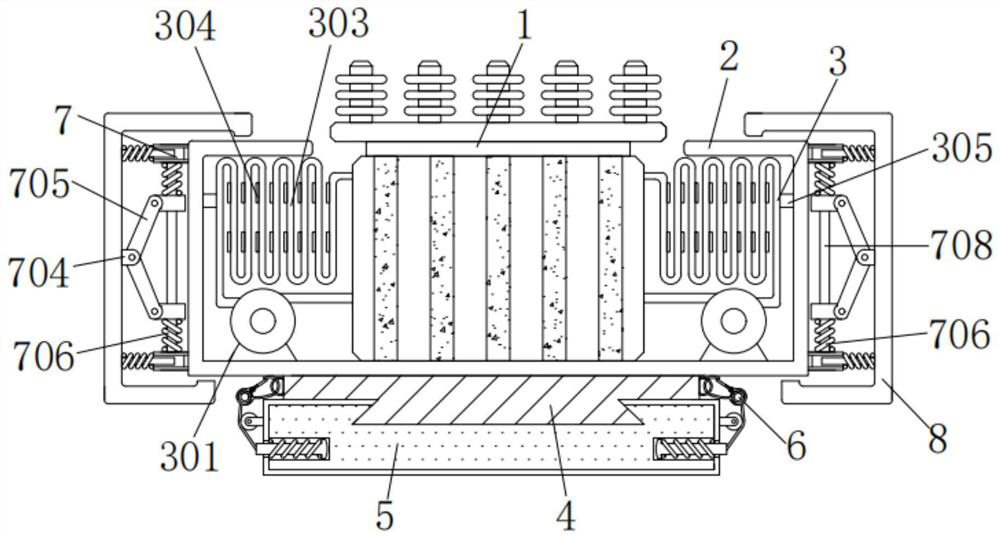

[0033] A new type of high-performance transformer, including a transformer 1 and a casing 2, the bottom of the transformer 1 is fixedly connected to the casing 2, the model of the transformer 1 is SCB11, and a cooling device 3 is provided inside the casing 2, and the cooling device 3 includes a bracket 301 and a water pump 302 , ring pipe 303, cooling plate 304 and short plate 305, the bottom of the bracket 301 is fixedly connected to the bottom left side of the inner wall of the shell 2, the model of the water pump 302 is 100WQ65-22-7.5, the top of the bracket 301 is fixedly connected to the bottom of the water pump 302 , the output end of the water pump 302 is connected with the lower right side of the transformer 1, and the input end of the water pump 302 is fixedly connected with the bottom left side of the ring pipe 303. After the cooling liquid is sucked out and cooled by the refrigerating sheet 304, it is transported again to the transformer 1 for heat dissipation. The u...

Embodiment 2

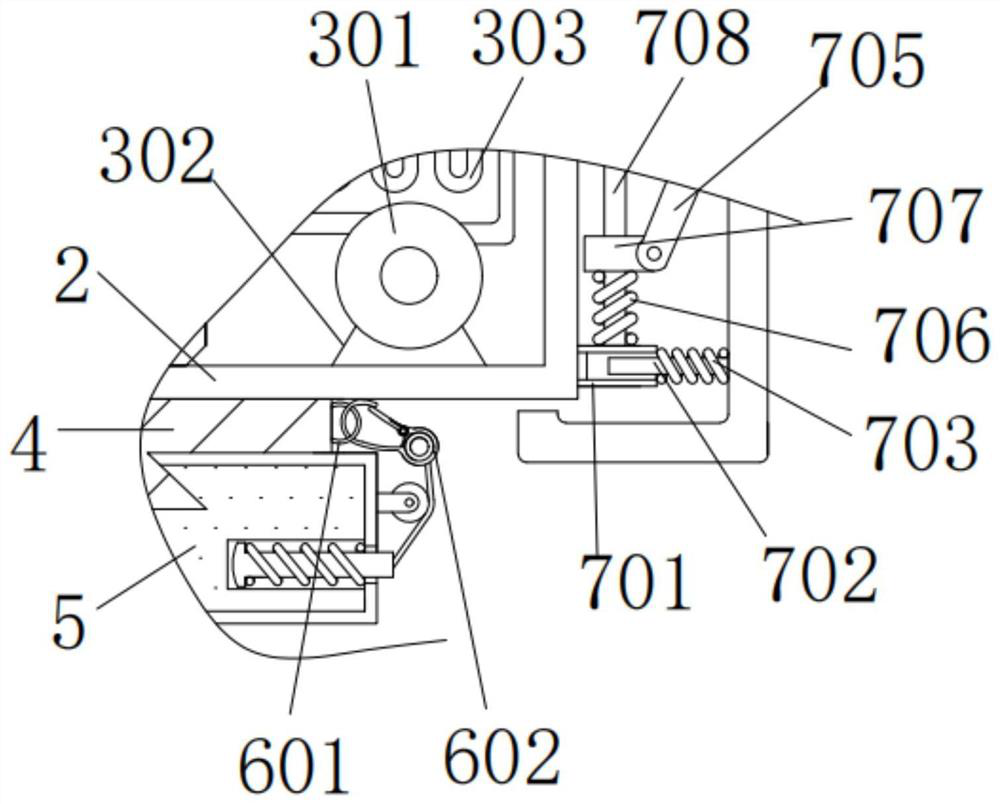

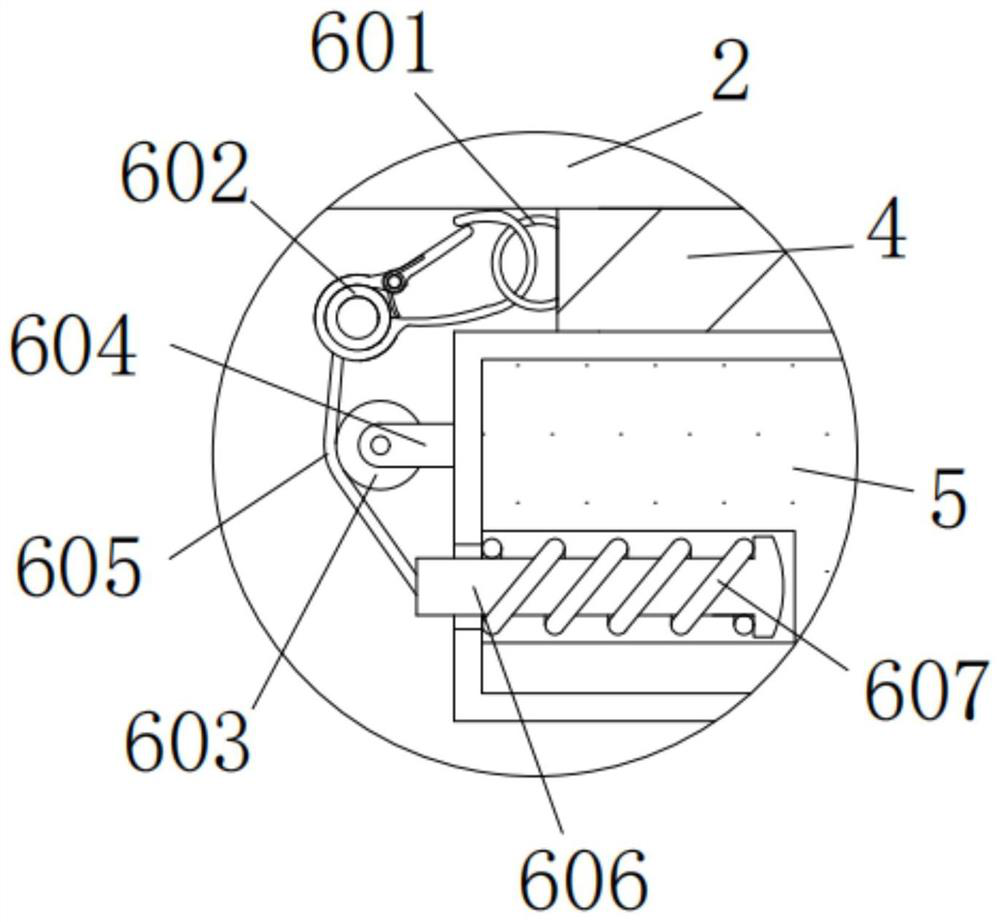

[0035] As an option, see Figure 1-3, a new high-performance transformer, both sides of the base 5 are provided with a fixing device 6, the fixing device 6 includes a ring 601, a buckle 602, a round wheel 603, a horizontal plate 604, a thick rope 605, a thick rod 606 and a first spring 607 , the right end of the ring 601 is fixedly connected to the left side of the wide plate 4, the inner wall of the ring 601 is movably connected with the inner wall of the buckle 602, and the buckle 602 can be clamped in the inside of the ring 601 for fixing, and the buckle can be fixed during transportation. The buckle 602 is removed to achieve separation. The bottom of the buckle 602 is provided with a thick rope 605. The bottom of the thick rope 605 is fixedly connected with the left bottom of the buckle 602. The right side of the thick rope 605 is attached to the left side of the round wheel 603. Together, the front of the round wheel 603 is connected to the left side of the rear end surfa...

Embodiment 3

[0038] As an option, see figure 1 , 2 , 4, 5 and 6, new high-performance transformers, the outside of the shell 2 is provided with a buffer device 7, the buffer device 7 includes a sleeve 701, a cross bar 702, a second spring 703, a block 704, a long plate 705, and a third spring 706 , slider 707 and slide bar 708, the right end of the sleeve 701 is fixedly connected to the top left side of the outer wall of the housing 2, the inner wall of the sleeve 701 is matched with the right side of the outer wall of the cross bar 702, and the cross bar 702 can be mounted on the sleeve 701 Inner wall moves left and right, and the left side of cross bar 702 is provided with curved plate 8, and the upper right side of curved plate 8 is fixedly connected with the left side of cross bar 702, and the outer wall of cross bar 702 is provided with second spring 703, and the second spring 703 The inner wall is socketed with the outer wall of the cross bar 702. When the curved plate 8 is subjecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com