Vibrator loudspeaker and implementation method thereof

An implementation method and speaker technology, applied in the field of vibrator speakers, can solve the problems of limited height compression space, cumbersome production process, low production cost, etc., and achieve the effects of more linear vibration, reduced production process, and saved height space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

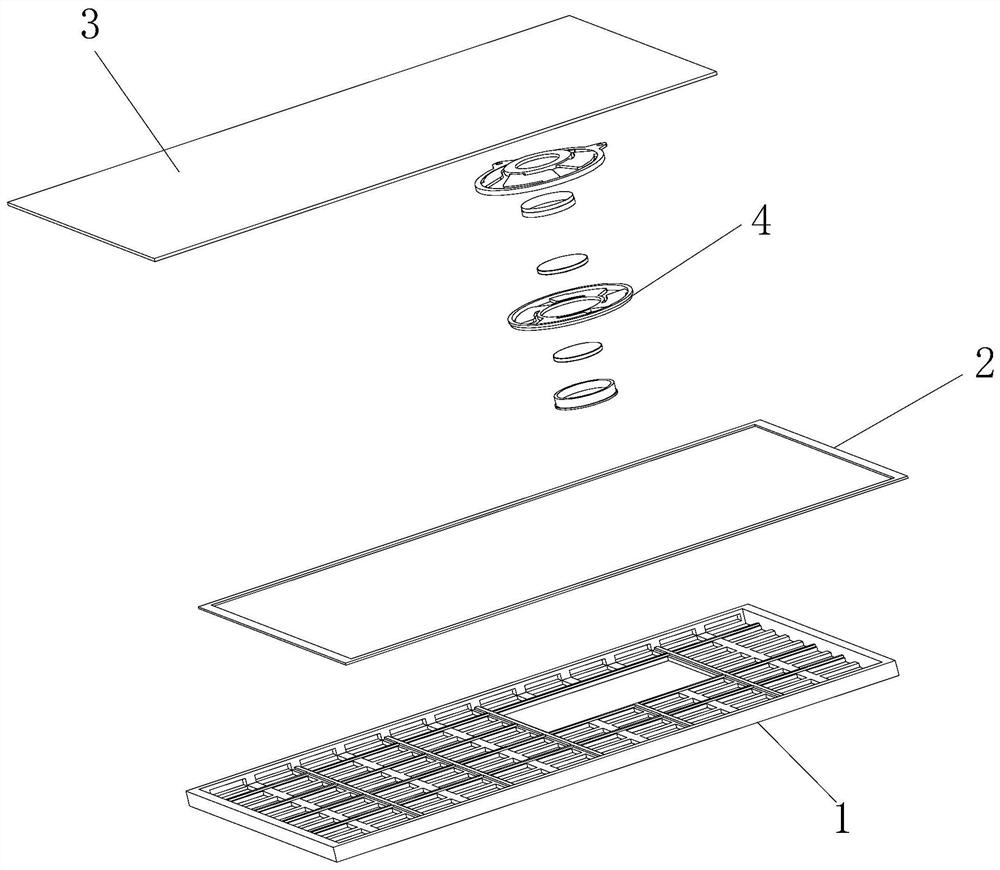

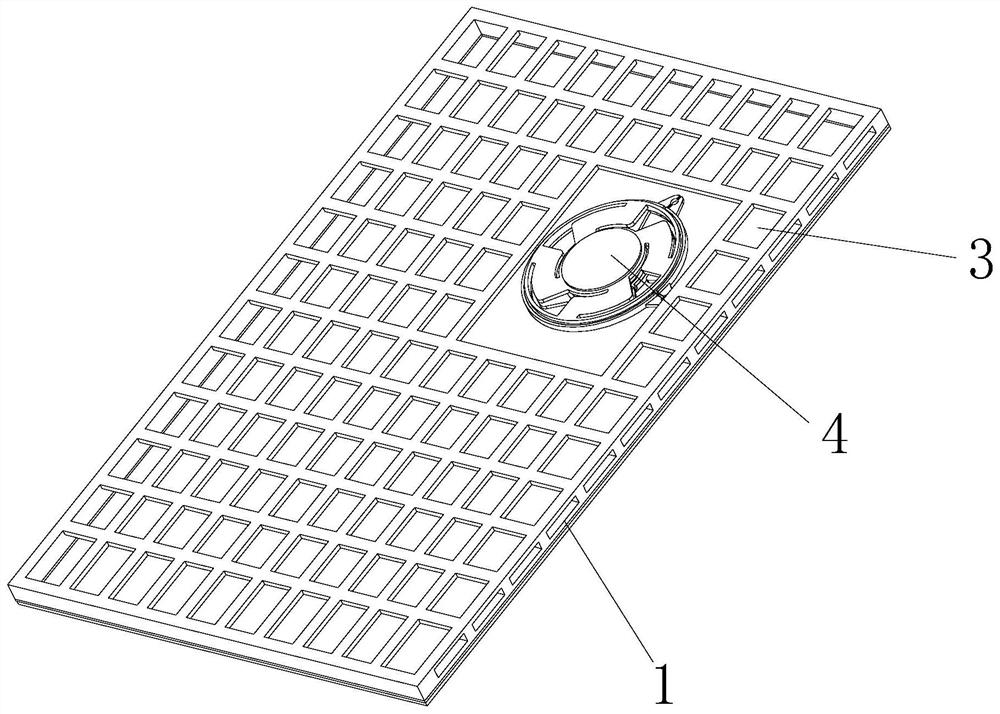

[0031] see Figure 1-5 , the present invention provides the following technical solutions: a vibrator speaker, including a bracket 1, a honeycomb panel 3 is arranged above the bracket 1, a speaker body 4 is connected to the honeycomb panel 3, and the speaker body 4 is located between the bracket 1 and the honeycomb panel 3, Loudspeaker body 4 comprises upper cover 41, voice coil 42, lower cover 43, magnetic steel 45 and U iron 46, wherein, upper cover 41 is connected with honeycomb panel 3, voice coil 42 is embedded in the inside of upper cover 41, lower cover 43 and The upper cover 41 is connected, the inside of the lower cover 43 is connected with a U-iron 46, the magnetic steel 45 is embedded in the inside of the U-iron 46, and the support 1 and the honeycomb panel 3 are rectangular structures.

[0032] Further, an upper splint 44 is connected above the magnetic steel 45 .

[0033] By adopting the above technical solution, the upper splint 44 conducts magnetic conduction, ...

Embodiment 2

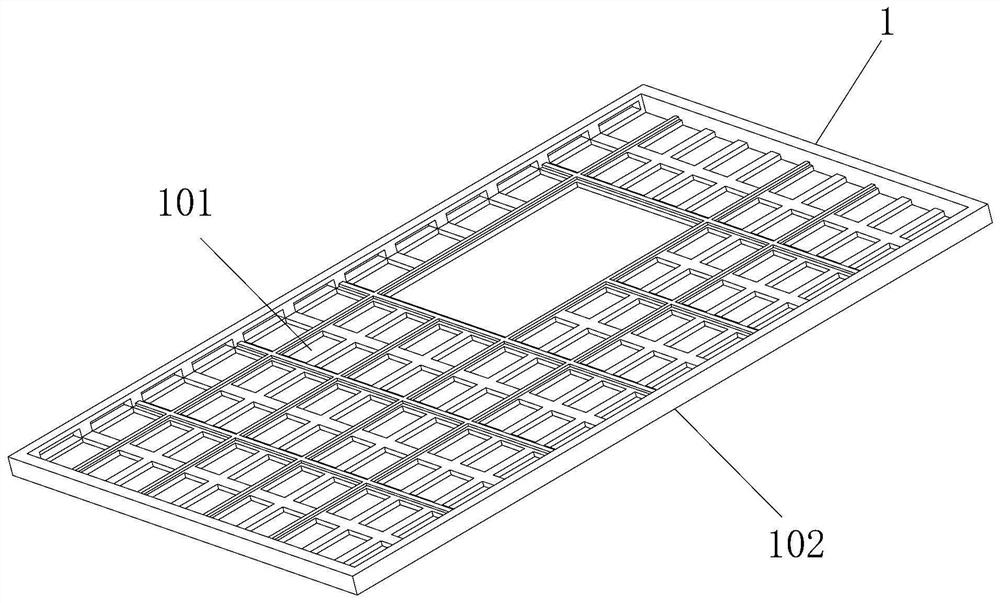

[0039] The difference between this embodiment and Embodiment 1 lies in: further, several rectangular grooves 101 are uniformly provided inside the bracket 1 .

[0040] By adopting the above technical solution, the rectangular groove 101 can reduce the blocking of sound waves and increase the rigidity of the bracket 1 .

[0041] Further, the implementation method of the vibrator speaker described in the present invention includes the following steps:

[0042] (1), the voice coil 42 is bonded to the inside of the loam cake 41;

[0043] (2), upper splint 44 and magnetic steel 45 are bonded together, and are bonded in the inside of U iron 46, and U iron 46 injection molding is connected in the inside of lower cover 43;

[0044] (3), the upper cover 41 and the lower cover 43 are buckled and connected, and the upper cover 41 is fixed on the honeycomb panel 3;

[0045] (4), the shock-absorbing cotton 2 is bonded on the flange 102 of the support 1, and the honeycomb panel 3 is bonde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com