Liquid cooling heat dissipation device of orthogonal architecture subrack

A liquid-cooling heat dissipation and liquid-cooling technology, which is applied in cooling/ventilation/heating transformation, electrical equipment structural parts, electrical components, etc. , to achieve the effect of less space occupation, flexible solution and high heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

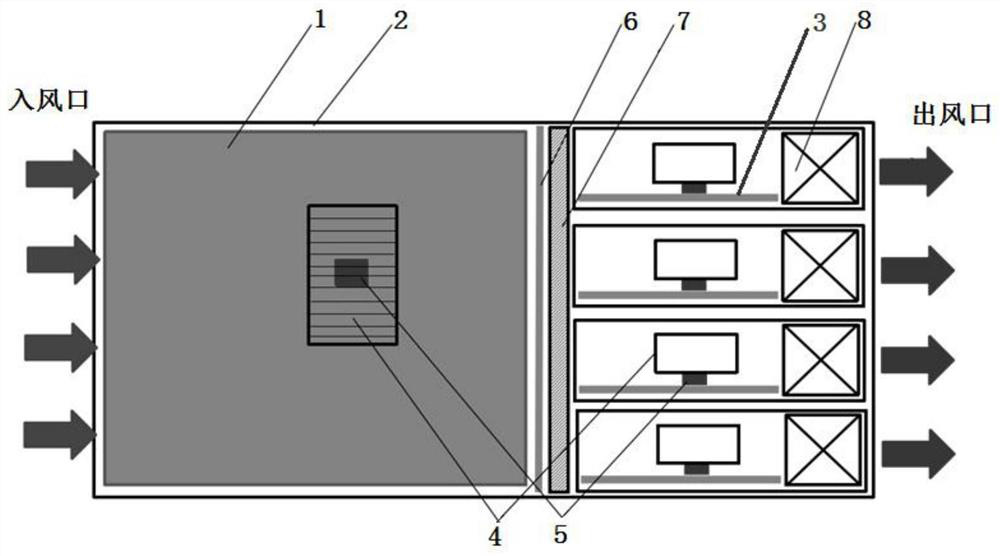

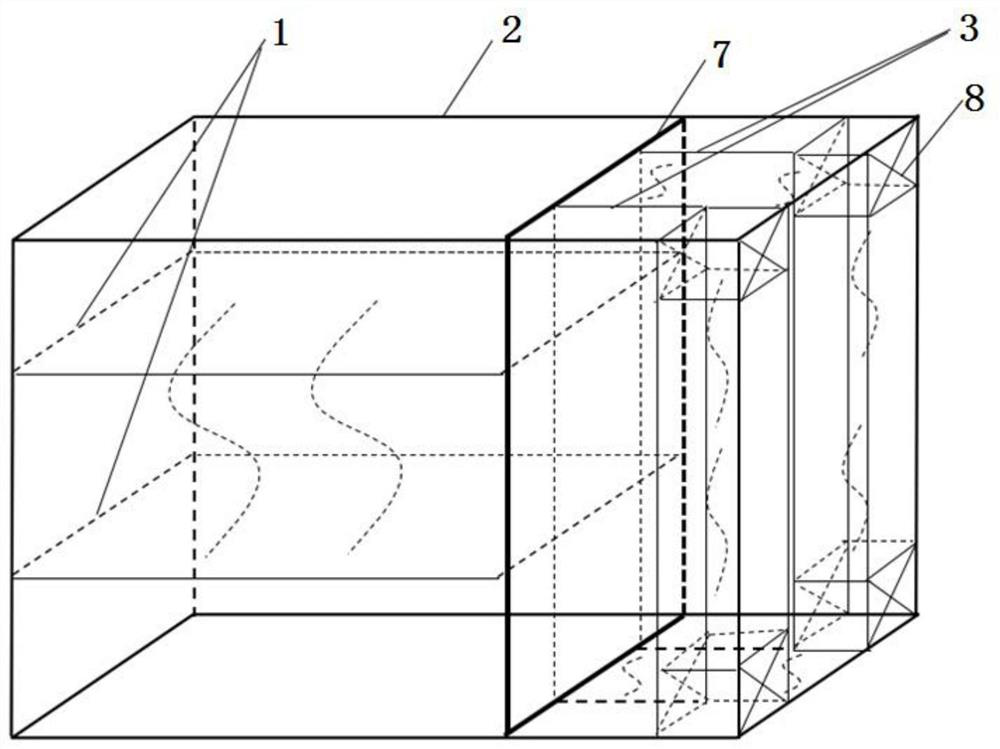

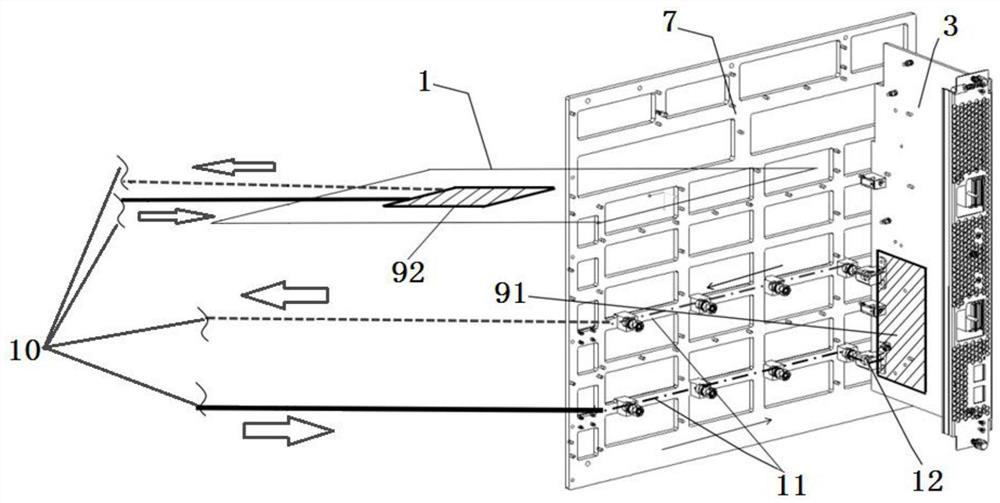

[0025] like image 3 Shown is a schematic diagram of the internal structure of the orthogonal structure sub-box liquid cooling heat dissipation device according to the present invention, the device includes an orthogonal structure sub-box and a liquid cooling heat dissipation device. The orthogonal structure subrack includes a box body, a line card 1, a keel 7, and a switch board 3. The line card 1 contains heat-generating devices, and the switch board 3 also contains heat-generating devices. Liquid cooling channels. The line card 1 and the switch board 3 are connected in an orthogonal manner through the keel 7 . The liquid cooling heat dissipation device includes a liquid cooling source 10 , a first cold plate 91 located on the exchange plate, a blind plug liquid cooling connector 12 and a keel liquid cooling fluid channel 11 . The liquid cooling fluid channel 11 is connected to the cooling source 10 through pipes (including liquid inlet pipes and liquid outlet pipes). Whe...

Embodiment 2

[0029] The working liquid channel on the keel 7 can only supply the second cold plate 92 on the line card 1, and only provide heat dissipation for the line card 1. The corresponding device structure of this design is: including the box body and the line card 1, keel 7 and exchange board 3 inside the box body. The line card 1 contains heating devices, and the exchange board 3 also contains heating devices. The keel 7 is used as a liquid cooling heat dissipation The channel is provided with a liquid cooling channel. The line card 1 and the switch board 3 are connected in an orthogonal manner through the keel 7 . The device also includes a liquid cooling heat dissipation device. The liquid cooling heat dissipation device uses the keel 7 as the carrier of the liquid cooling fluid channel 11, and the keel 7 is also used as the installation carrier of the blind plug liquid cooling connector 12; the keel 7 is provided with a closed channel as a liquid The cold fluid channel 11, the ...

Embodiment 3

[0031] Usually, in the orthogonal frame subrack liquid cooling heat sink, the liquid cooling source is placed outside the orthogonal frame subbox, and the liquid cooling source can be set under the orthogonal frame subbox, such as Figure 5 shown.

[0032] The present invention proposes a liquid cooling device with an orthogonal structure and a built-in cold source. The cold source can be arranged inside the device, which saves space, shortens the length of the pipeline for the working liquid to flow into the cold source, and further improves the cooling efficiency. The design utilizes existing fan systems to cool cold sources such as Figure 4 shown. Multiple cold sources 10 can also be provided, and each cold source is placed inside the exchange box 13 to dissipate heat for the corresponding exchange plate, further improving the design flexibility and heat dissipation efficiency of the heat dissipation device. The device also includes an air-cooled heat dissipation system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com