Combine and harvester

A combine harvester and harvester technology, which is applied in agricultural machinery and implements, threshing equipment, applications, etc., can solve the problems of complex supporting structure and high cost, and achieve the effect of simple unloading operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

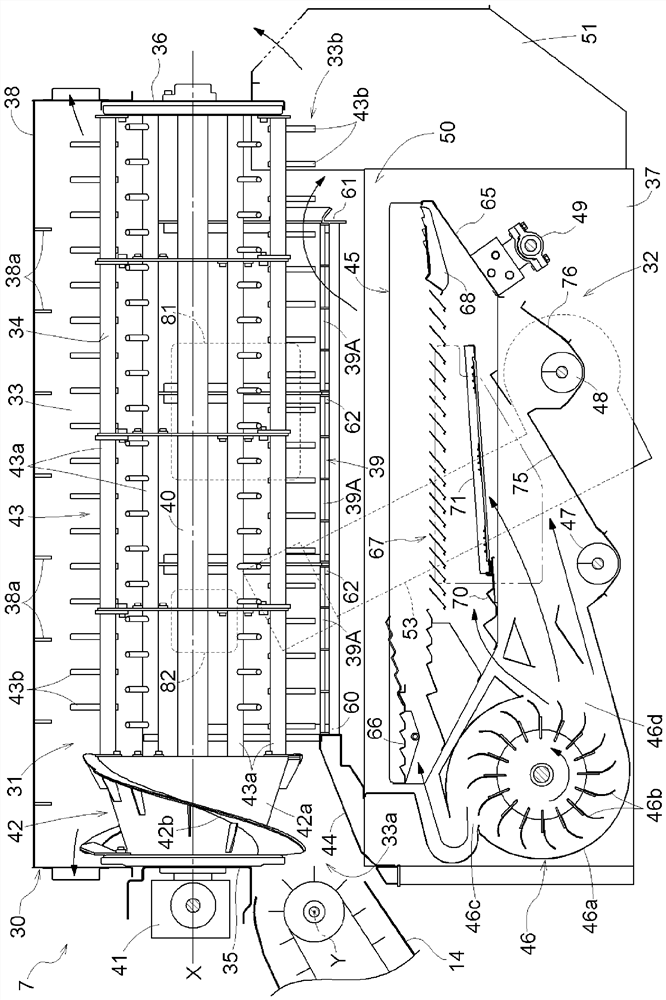

[0078] Hereinafter, a first embodiment of the present invention will be described based on the drawings.

[0079] [Basic structure of the combine harvester of the first embodiment]

[0080] exist figure 1 , 2 , 3 have shown the whole combine of this embodiment. Right now, figure 1 represents the left view, figure 2 represents the right view, image 3 Represents a plan view, and in these figures, the direction [F] is defined as the front of the traveling body 1, and the direction [B] is defined as the rear of the traveling body 1, image 3 The indicated direction of [L] is defined as the left side of the traveling body 1 , and the direction of [R] is defined as the right side of the traveling body 1 .

[0081] like figure 1 , 2 As shown in , 3 , the combine harvester is provided with a driver's seat 4 on the right front part of the traveling body 1 that can move freely by means of a pair of left and right crawler belt traveling devices 2 . In the cab 3 , a cabin 5 is ...

no. 2 Embodiment approach

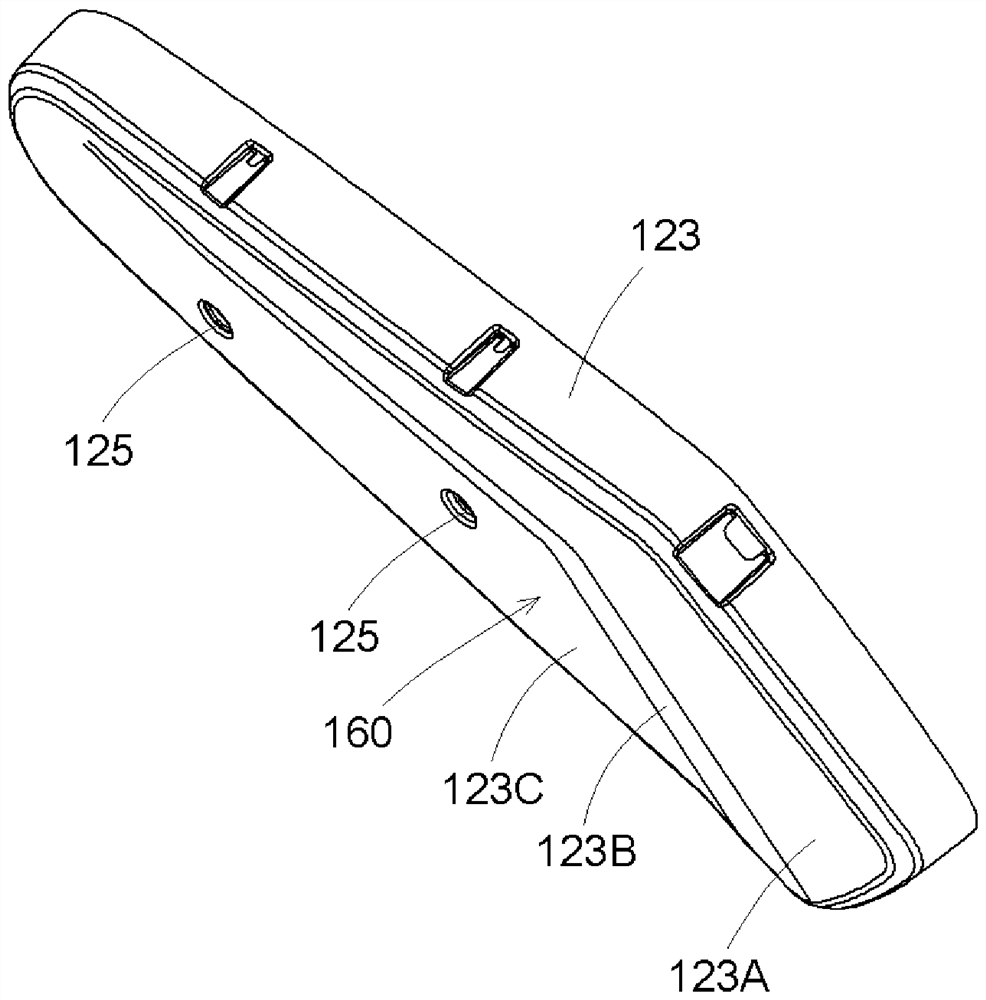

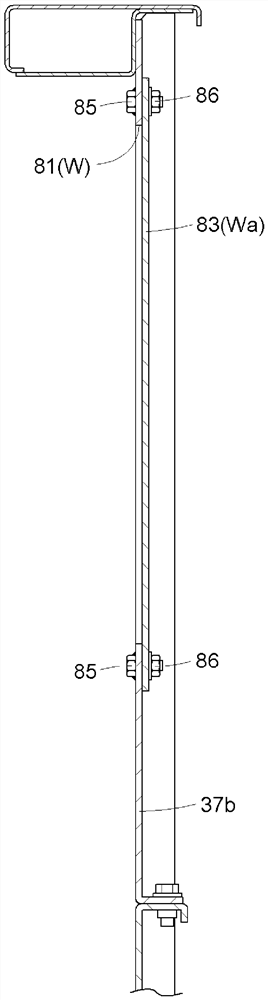

[0137] Hereinafter, the case where 2nd Embodiment of this invention is applied to the ordinary type combine which is an example of a combine is demonstrated based on drawing.

[0138] [Overall structure of the second embodiment]

[0139] like Figure 9 , 10 , 11, the common type combine harvester is equipped with a driving unit 103 on the right side of the front part of the traveling body 102 equipped with a pair of crawler belt traveling devices 101, and is equipped with a threshing device 104 for threshing the harvested crops. The grain storage part 105 of the grain storage apparatus which stores the grain obtained by the threshing process. Grain storage unit 105 is equipped with the state that is positioned at the rear side of driving unit 103, and grain storage unit 105 is positioned at the right side of the body and threshing device 104 is positioned at the state of the left side of the body. The valley devices 104 are placed and supported on the body frame 106 so as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com