Adjustable workpiece grinding machine

A workpiece and mechanical technology, which is applied in the field of adjustable workpiece grinding machinery, can solve the problems of inconvenient processing of the inner wall of the bell mouth, etc., and achieve the effects of improving grinding efficiency, reducing vibration and improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

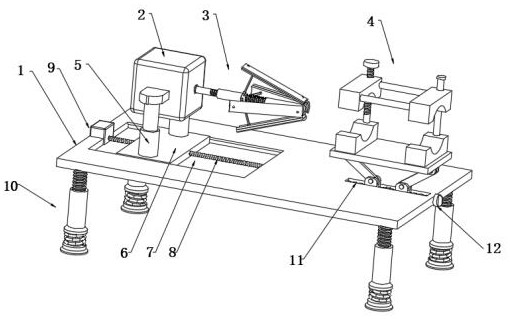

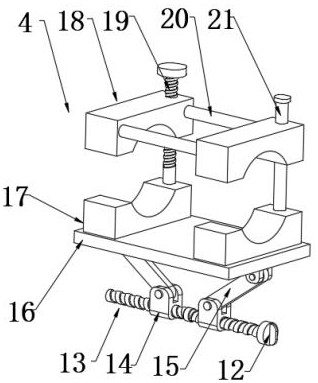

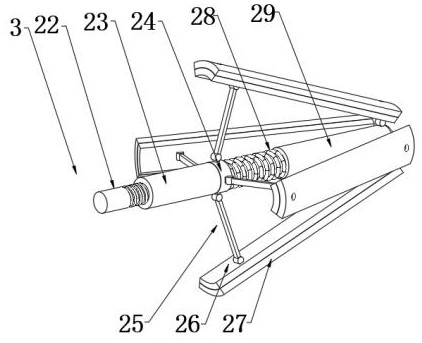

[0026] see Figure 1-5 , an adjustable workpiece grinding machine, including a working panel 1, a grinding motor 2, a grinding head mechanism 3 and a fixing mechanism 4, the working panel 1 is provided with a chute 7, and the chute 7 is provided with an adapted Mounting plate 6, the mounting plate 6 is slidingly connected with the chute 7 and the grinding motor 2 is installed on the mounting plate 6, the grinding motor 2 can be driven to move along the chute 7 through the mounting plate 6, and the grinding head mechanism 3 includes a first connecting rod 22 and the second connecting rod 29 connected to one end of the first connecting rod 22, the first connecting rod 22 is provided with a spring 28, the spring 28 is sleeved on the first connecting rod 22 and one end of the spring 28 is connected to the second connecting rod 29 connection, the other end is connected with one end of the movable block 24 arranged on the first connecting rod 22, and the movable block 24 is slidably...

Embodiment 2

[0033] In order to reduce the vibration of the adjustable workpiece during work, this embodiment is further improved on the basis of Embodiment 1. The improvement is: a backing plate 32 is provided under the pad leg 10, and the backing plate 32 A shock-absorbing mechanism 31 is arranged between the pad leg 10, and the shock generated by the adjustable workpiece during work can be effectively weakened by the shock-absorbing mechanism 31.

[0034] Described damping mechanism 31 comprises damping spring and damping cylinder, and damping spring is sleeved outside the damping cylinder, and one end of damping spring and damping cylinder is connected with pad leg 10, and the other end is connected with backing plate 32, through damping Shock springs and shock-absorbing cylinders can reduce the vibration of adjustable workpieces during work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com