Automatic vibrating diaphragm punching equipment

An automatic punching and equipment technology, applied in metal processing, sending objects, thin material processing, etc., can solve the problems of affecting the sound quality of speakers, affecting the yield rate, and low work efficiency, so as to ensure accuracy, ensure good product rate, and improve work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

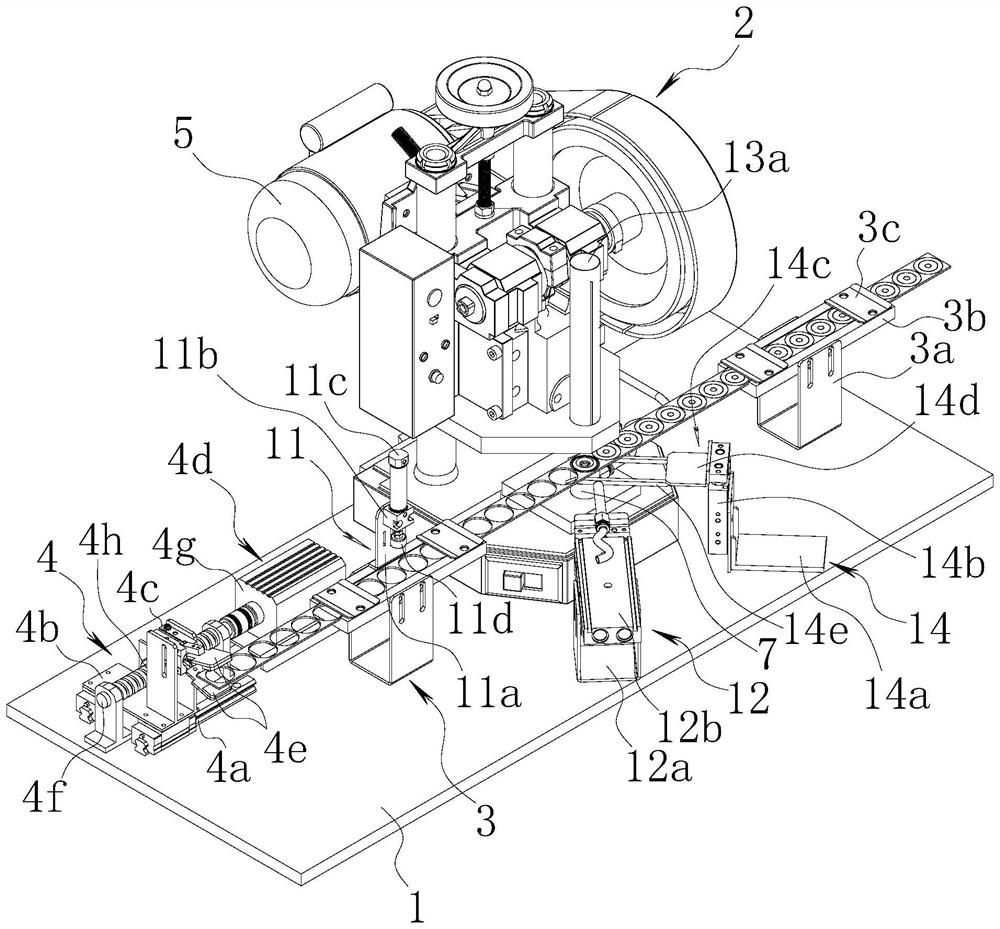

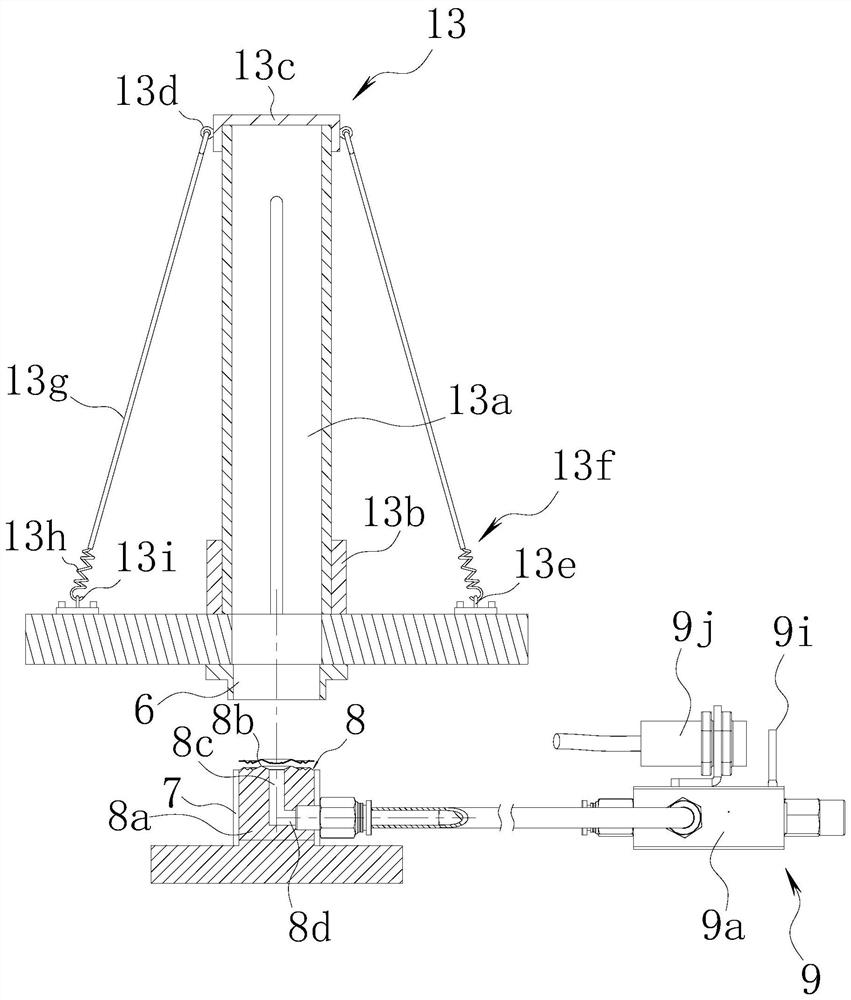

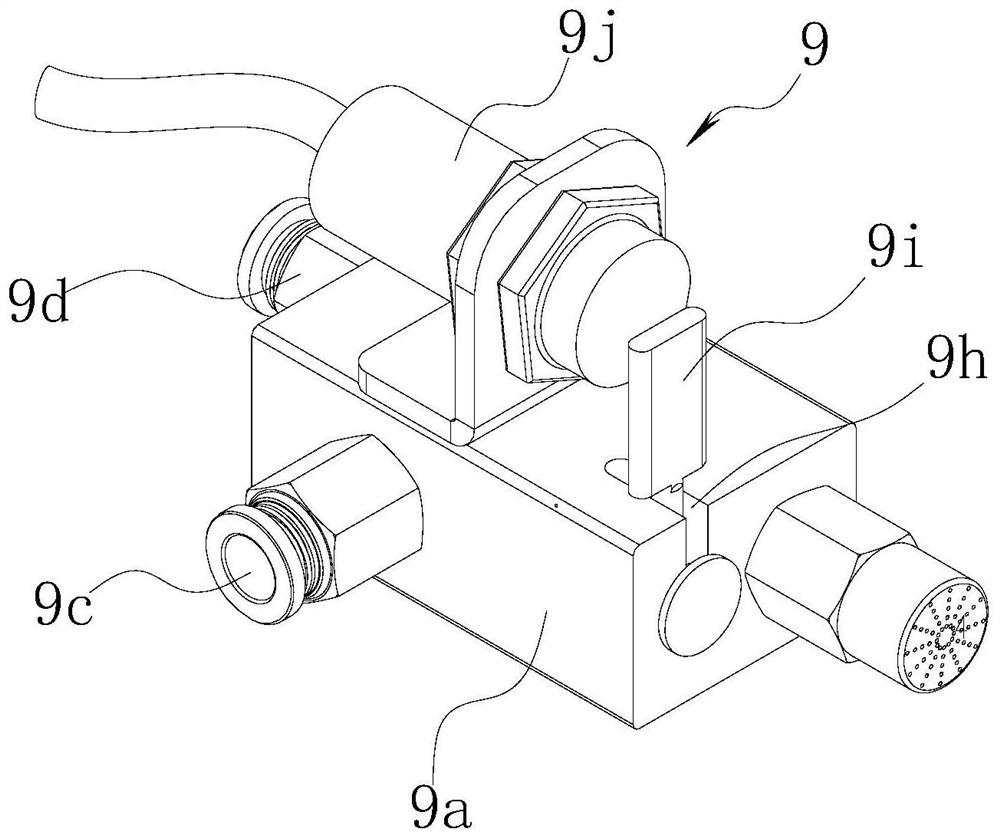

[0031]refer to Figure 1 to Figure 5 As shown, a kind of vibrating film automatic punching equipment of the present invention comprises workbench 1, and described workbench 1 is provided with automatic punching device 2, is provided with to be punched vibrating film on the side of automatic punching device 2 The guide mechanism 3 that is suitable for the strip; the automatic traction mechanism 4 that pulls the moving diaphragm strip to be punched is provided on the workbench 1; the automatic punching device 2 includes a punch 5, and the punch 5 is provided with a punching and The upper mold 6 and the lower mold 7 of the diaphragm are provided with an auxiliary locator 8 inside the lower mold 7, and the upper end surface of the auxiliary locator 8 is adapted to the diaphragm on the diaphragm strip to be punched. The auxiliary locator and the lower die can be of an integrated structure or a separate structure, depending on the specific circumstances.

[0032] The auxiliary posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com