Side mold sweeping and spraying machine based on concrete prefabricated part

A technology of prefabricated components and spraying machines, which is applied in the direction of manufacturing tools and ceramic molding machines, etc. It can solve the problems of post-processing operation of side molds, dependence on manpower, environmental pollution of workshops, etc., and achieve time-saving and labor-saving operation safety and high degree of automation , Improve the effect of the applicable surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

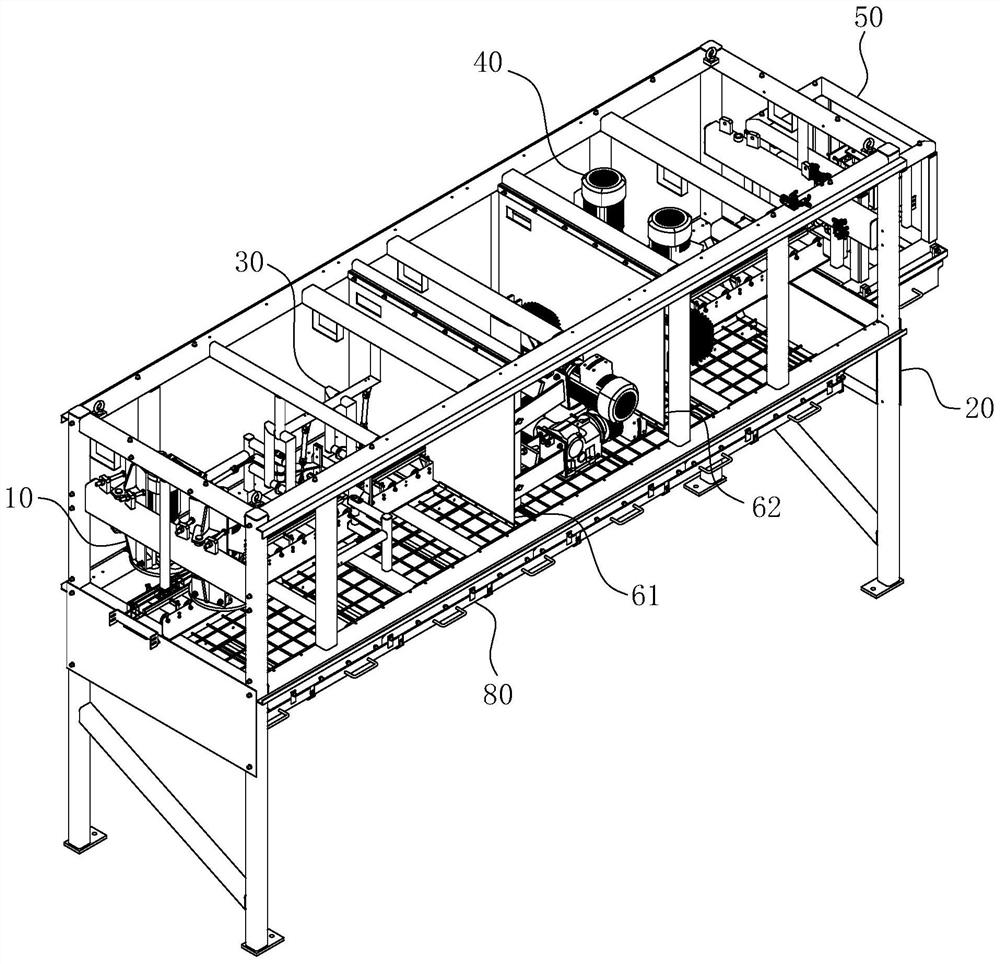

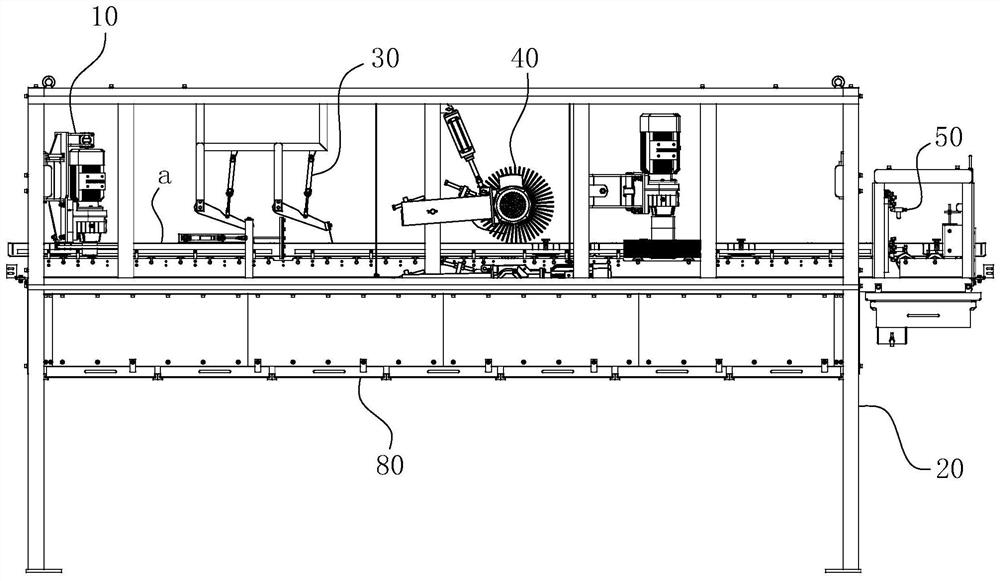

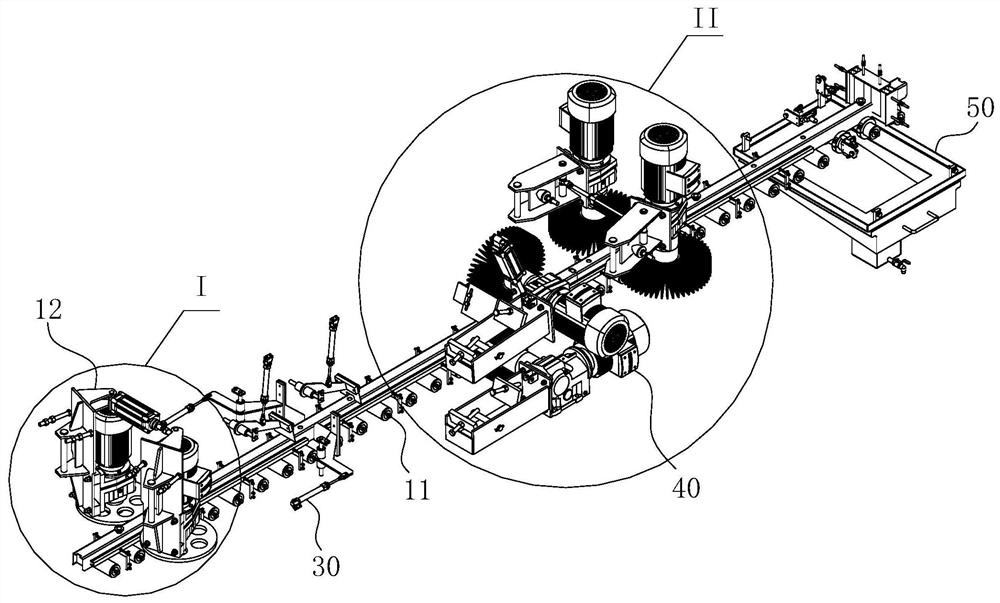

[0054] For the convenience of in-depth understanding of the present invention, combined here Figure 1-10 , the concrete structure of the present invention and working mode are described as follows:

[0055] The side mold a is actually a solid straight rod-shaped or hollow straight tube-shaped part fixed on the mold table; when in use, multiple side molds a are enclosed with each other to form a cavity structure with the opening facing upward on the mold table. In order to be used for cloth pouring to form specific PC components. After each PC component is formed and taken out, the side mold a needs to be dismantled and cleaned, and then sprayed with a release agent for repeated use.

[0056] Under the above general environment, the present invention provides such Figure 1-2 The shown side mold cleaning and spraying machine drives the side mold a forward by the conveying part 10, and then relies on the scraping assembly 30, the cleaning assembly 40 and the spraying assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com