Chili bean paste filling machine

A technology for red oil bean paste and filling machine, which is applied to mixers, packaging, mixers and other directions with a rotary stirring device, can solve the problems of long-term stability of accuracy, lack of stand-alone equipment, inconvenient adjustment, etc., and achieves small errors. , The error of filling volume is small, and the effect of flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

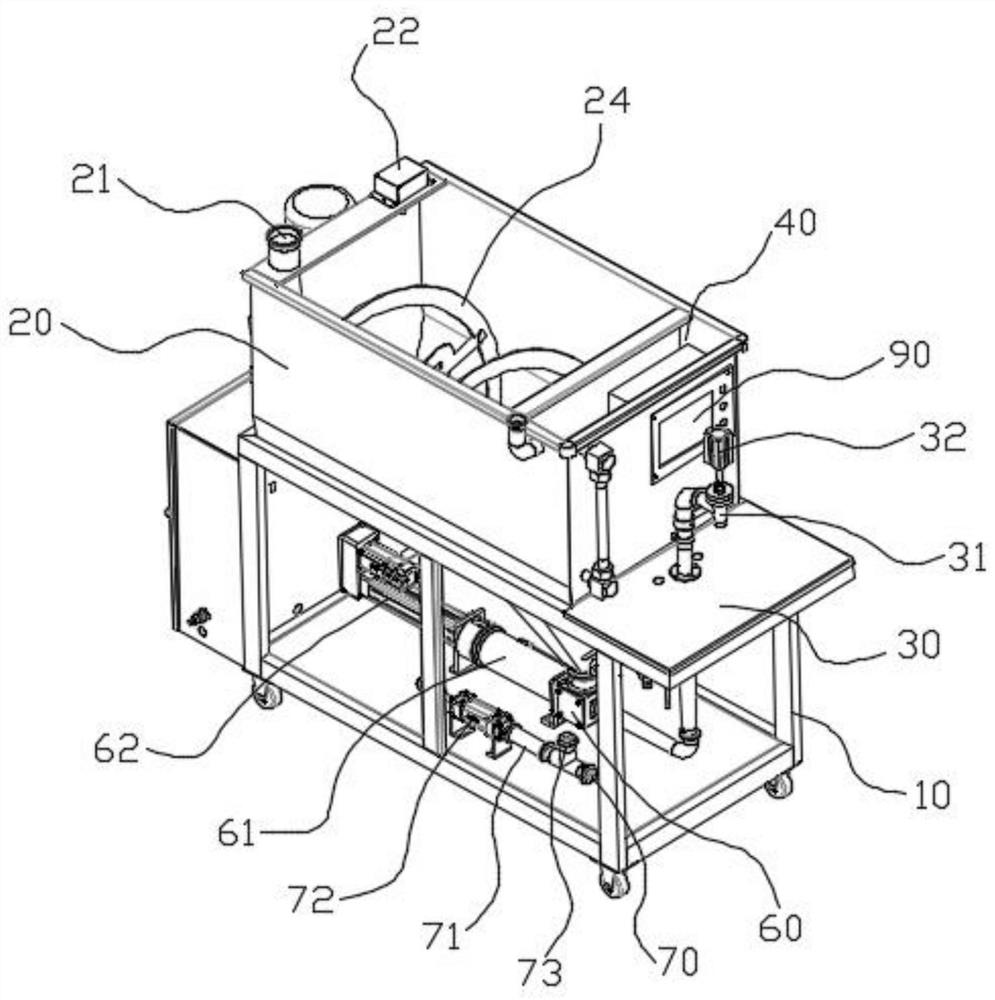

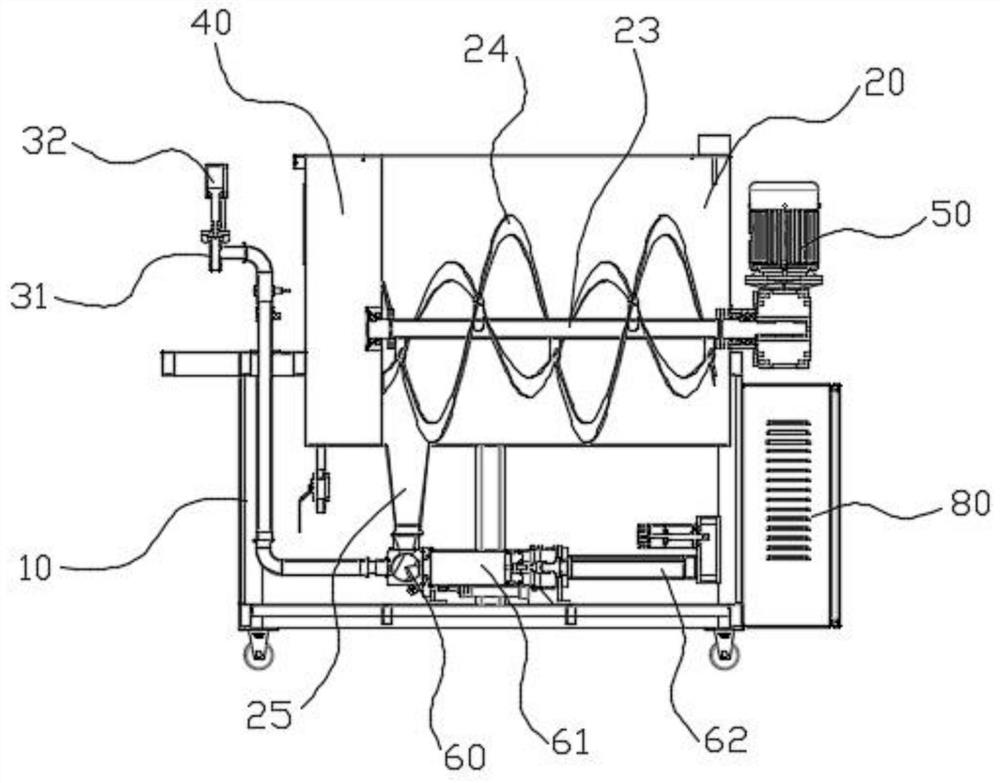

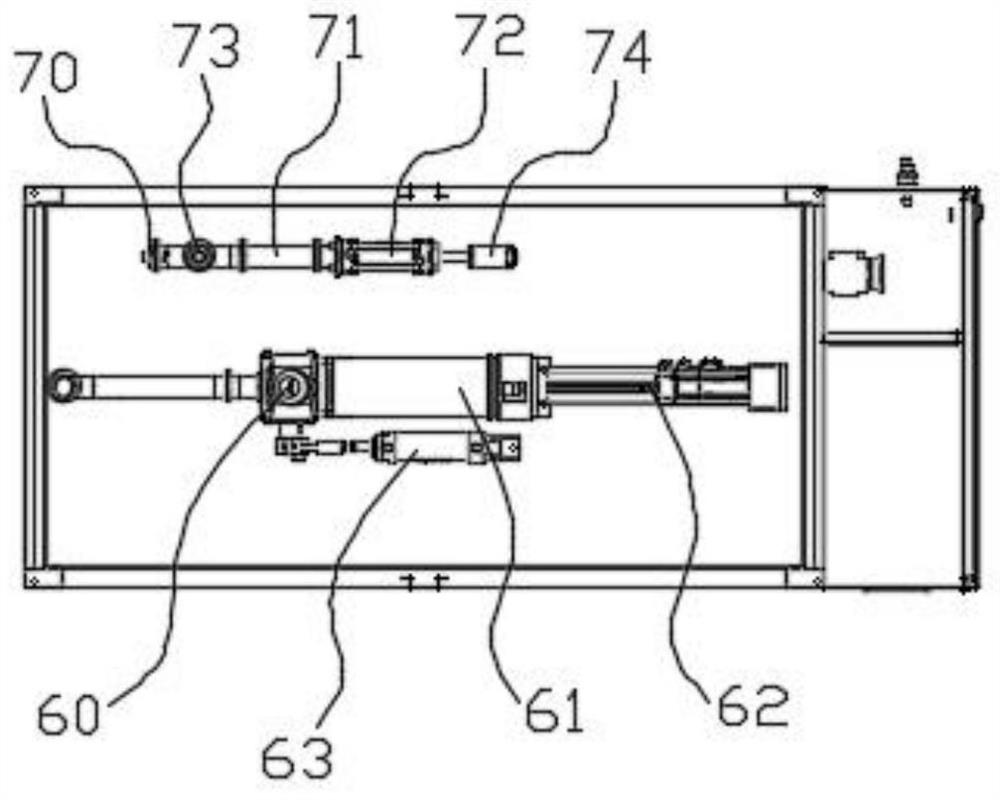

[0028] like Figure 1-Figure 3 As shown, a red oil bean paste filling machine includes a filling machine frame 10, a material barrel 20, a stirring mechanism located in the material barrel 20, and a filling nozzle 31, and the filling nozzle 31 is provided with a driving filling nozzle 31 The valve core opens or closes the filling nozzle cylinder 32, the material barrel 20 is provided with a feeding port 21 and a material level gauge 22, and the filling machine frame 10 is also provided with an oil barrel 40, and the oil barrel 40 is provided with a filling port , the outer wall of the oil drum 40 is provided with a connector for observing the amount of oil, and the filling machine frame 10 is provided with a material filling mechanism and an oil filling mechanism, and the input ends of the material filling mechanism and the oil filling mechanism are connected to the material barrel 20 and the oil filling mechanism respectively. The output end of the oil drum 40 is connected, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com