Core separation box for continuous coring with hydraulic reverse circulation in coal mine and method thereof

A technology of reverse circulation and separation box, which is applied in the direction of extracting undisturbed core devices, mining equipment, earthwork drilling and mining, etc., which can solve the problems of safety hazards and pressure relief gas not being collected, and achieve good airtightness, simple structure, and easy cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the purpose, technical features and technical effects of the technical solutions of the present invention clearer, the following will clearly and completely describe the exemplary solutions of the embodiments of the present invention with reference to the accompanying drawings of the specific embodiments of the present invention.

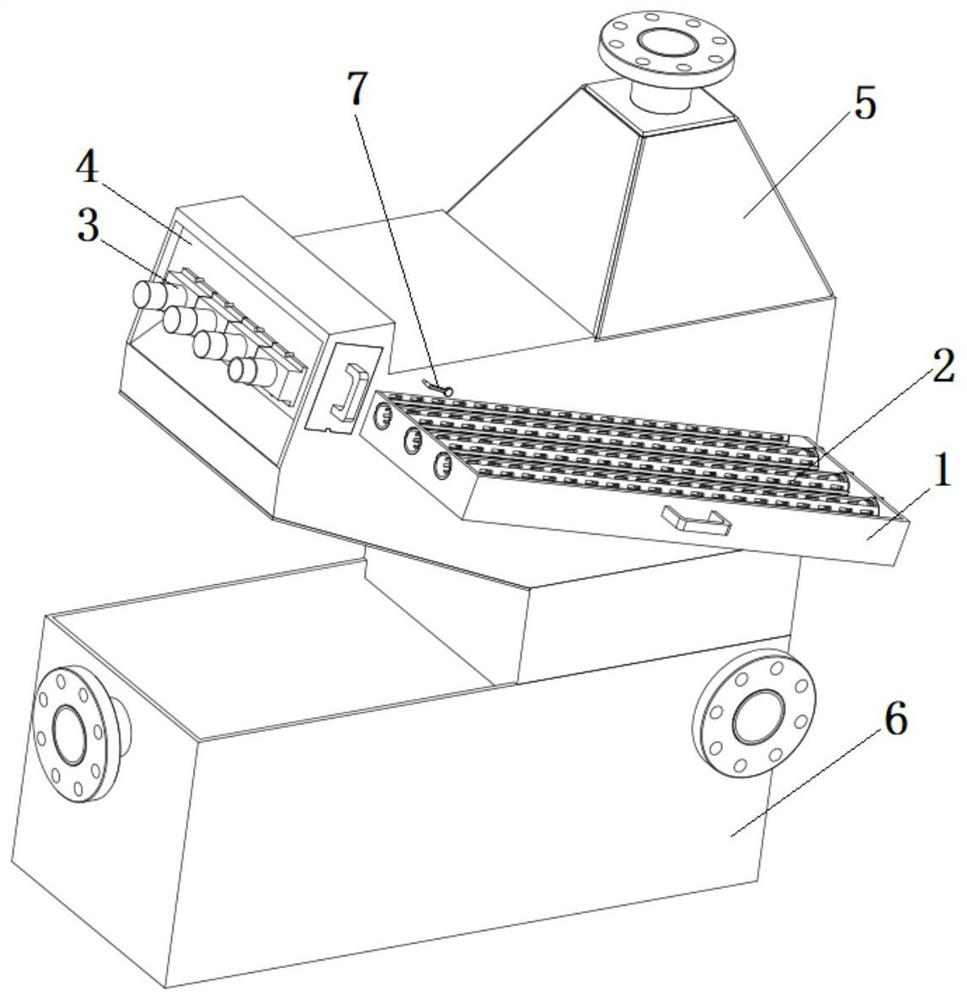

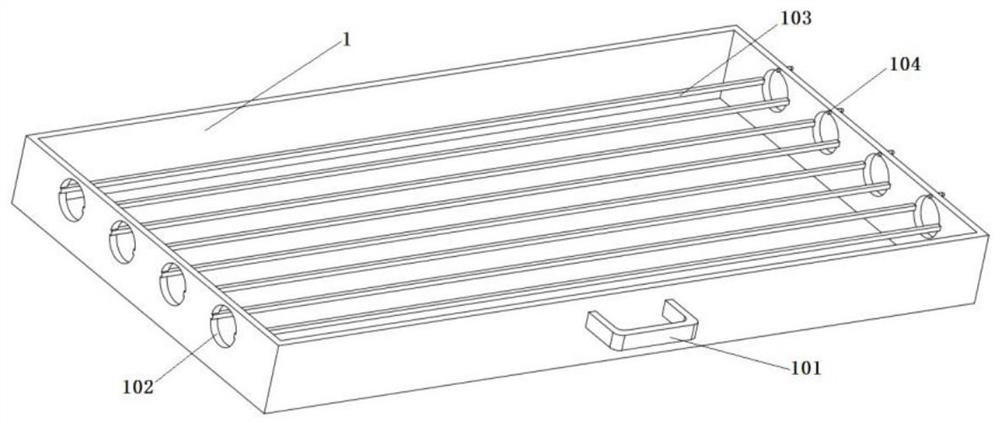

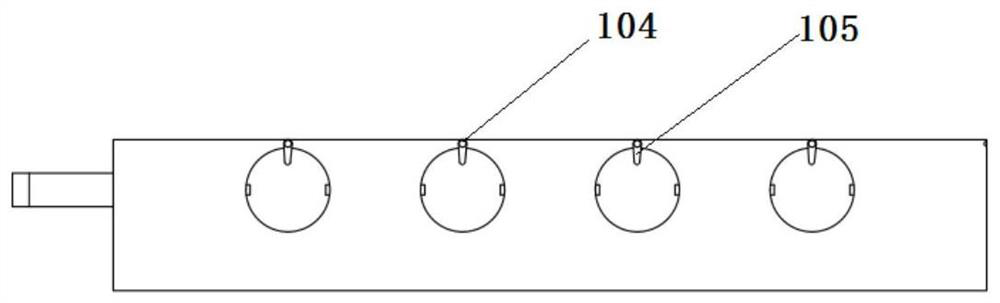

[0044] The embodiment of the present invention provides a core separation box for continuous coring with hydraulic reverse circulation in a coal mine, such as Figure 1-13 As shown, the core separation box may include a core cabinet 1, a core barrel 2, a sliding joint 3, a joint cabinet 4, a negative pressure extraction box 5, a sediment box 6 and a core signaling mechanism 7, such as figure 1 As shown in the figure, the core cabinet 1 and the joint cabinet 4 can be drawn out and arranged in the negative pressure extraction box 5, the sliding joint 3 is arranged in the joint cabinet 4, and the core barrel 2 has multiple Separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com