Corrugated pipe expansion joint and corrugated pipe

A bellows and expansion joint technology, applied in the field of bellows expansion joints and their bellows, can solve the problems of inconvenience, damage, instability of the bellows, etc., and achieve the effects of being convenient to use, avoiding damage, and avoiding damage to end pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

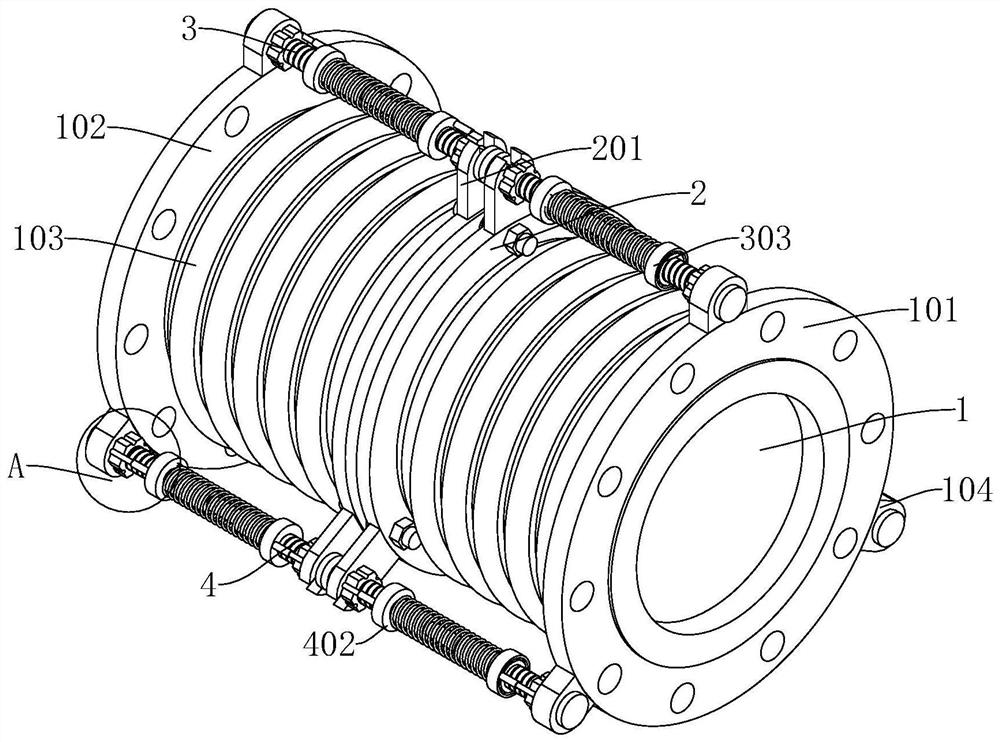

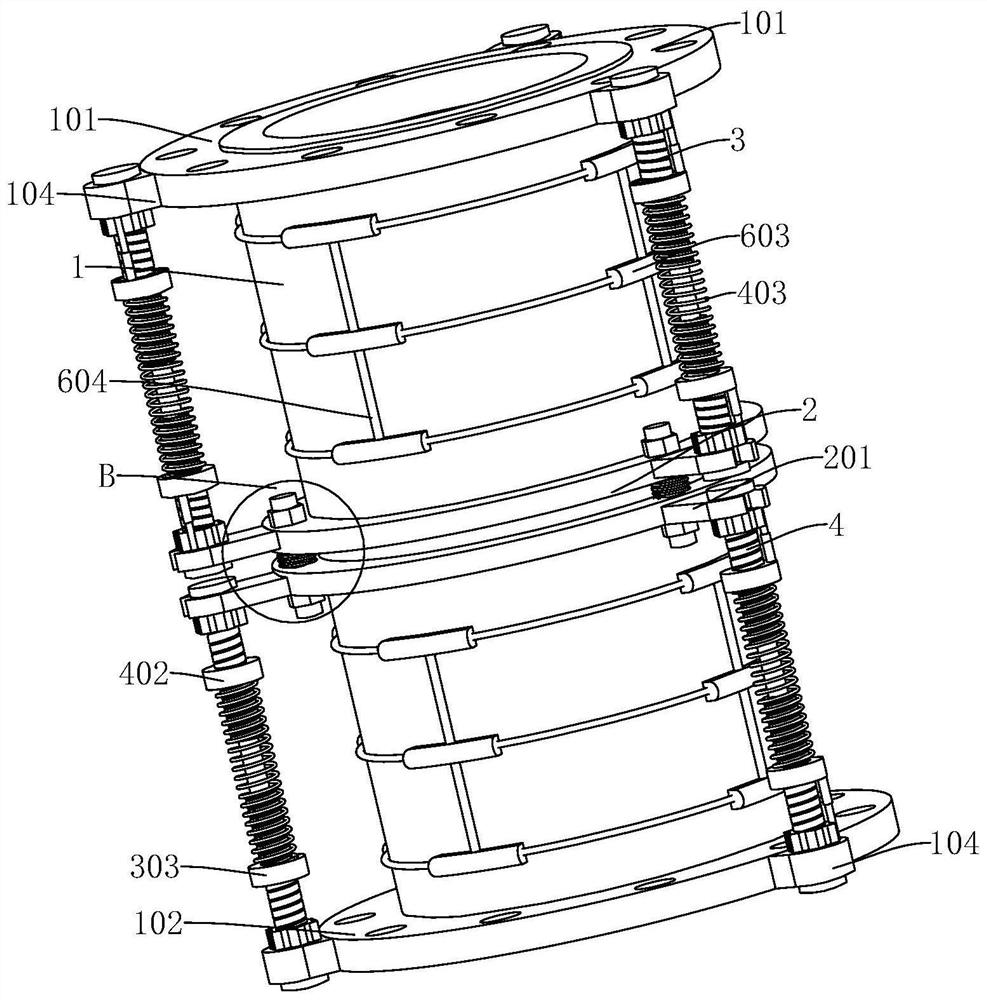

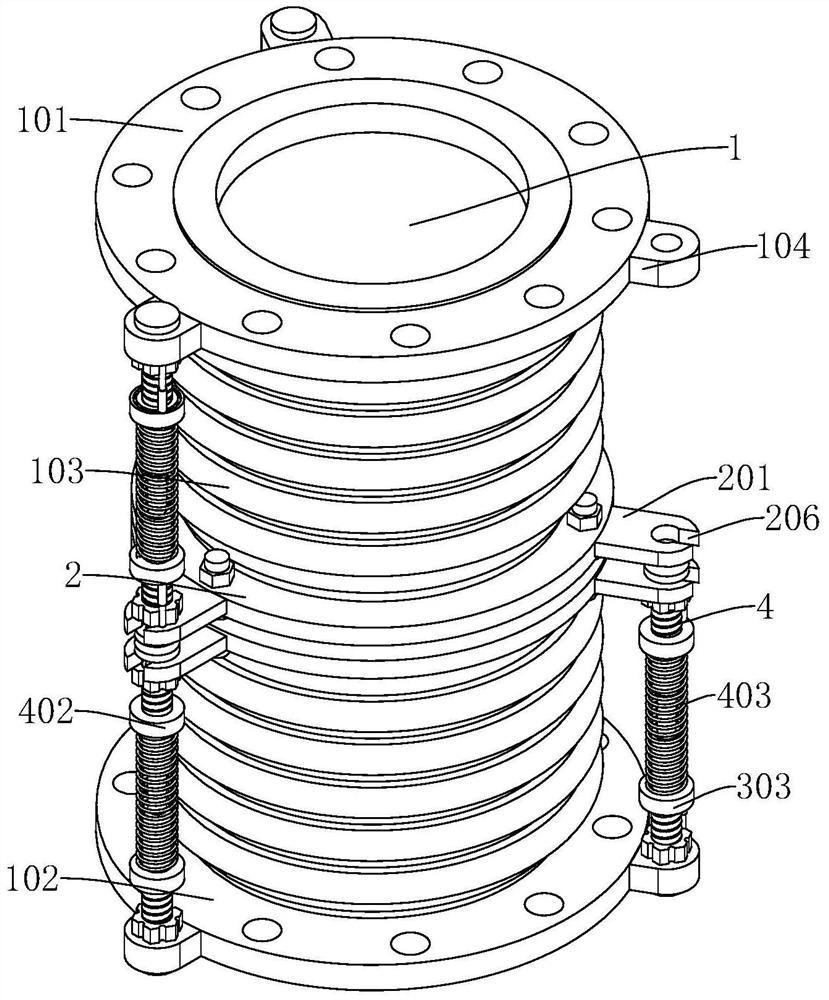

[0036] refer to Figure 1-10, a bellows expansion joint, including an end pipe 1, a first flange 101 and a second flange 102 are respectively provided on the outer walls of both sides of the end pipe 1, and two annular plates are sleeved on the middle outer wall of the end pipe 1 2. The bellows body 103 is sleeved between the first flange 101 and the ring plate 2 and the second flange 102 and the ring plate 2. The outer wall of the end pipe 1 is also provided with a bellows body 103. air bag 603;

[0037] Both the first flange 101 and the second flange 102 are fixedly connected with a first support ear 104, and the outer walls of the two annular plates 2 are connected with a second support ear 201 corresponding to the position of the first support ear 104, The first support ear 104 is connected with the first threaded rod 3, the second support ear 201 is connected with the second threaded rod 4, and the first threaded rod 3 is also provided with a stop rod 404, which is slida...

Embodiment 2

[0047] refer to Figure 1-9 , a bellows expansion joint, including an end pipe 1, a first flange 101 and a second flange 102 are respectively provided on the outer walls of both sides of the end pipe 1, and two annular plates 2 are connected to the middle outer wall of the end pipe 1 , a bellows body 103 is connected between the first flange 101 and the annular plate 2 and between the second flange 102 and the annular plate 2;

[0048] Both the first flange 101 and the second flange 102 are fixedly connected with a first support ear 104, and the outer walls of the two annular plates 2 are connected with a second support ear 201 corresponding to the position of the first support ear 104, The first support ear 104 is connected with the first threaded rod 3, the second support ear 201 is connected with the second threaded rod 4, and the first threaded rod 3 is also provided with a limit rod 404, which is slidably connected to the second threaded rod 404. On the threaded rod 4; ...

Embodiment 3

[0053] refer to Figure 1-9 , a bellows expansion joint, which is basically the same as that in Embodiment 1, furthermore, three sets of first support ears 104 and second support ears 201 are provided, and three sets of first support ears 104 and second support ears 201 are provided Both are respectively provided with a first threaded rod 3 and a second threaded rod 4, by setting three sets of first threaded rods 3 and second threaded rods 4, the force can be more uniform, and setting three sets can make it have a stable triangular shape. Sex, while saving material and space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com