Power supply fixing box

A technology for fixing boxes and power supplies, applied in circuit layout, lighting devices, components of lighting devices, etc., can solve the problems of unsmooth wiring, high overall cost, inconvenient efficiency, etc., and achieve convenient and fast installation and fixation. The effect of smooth passage and quick loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the description of the following embodiments is used to help understand the invention, but does not constitute a limitation to the invention.

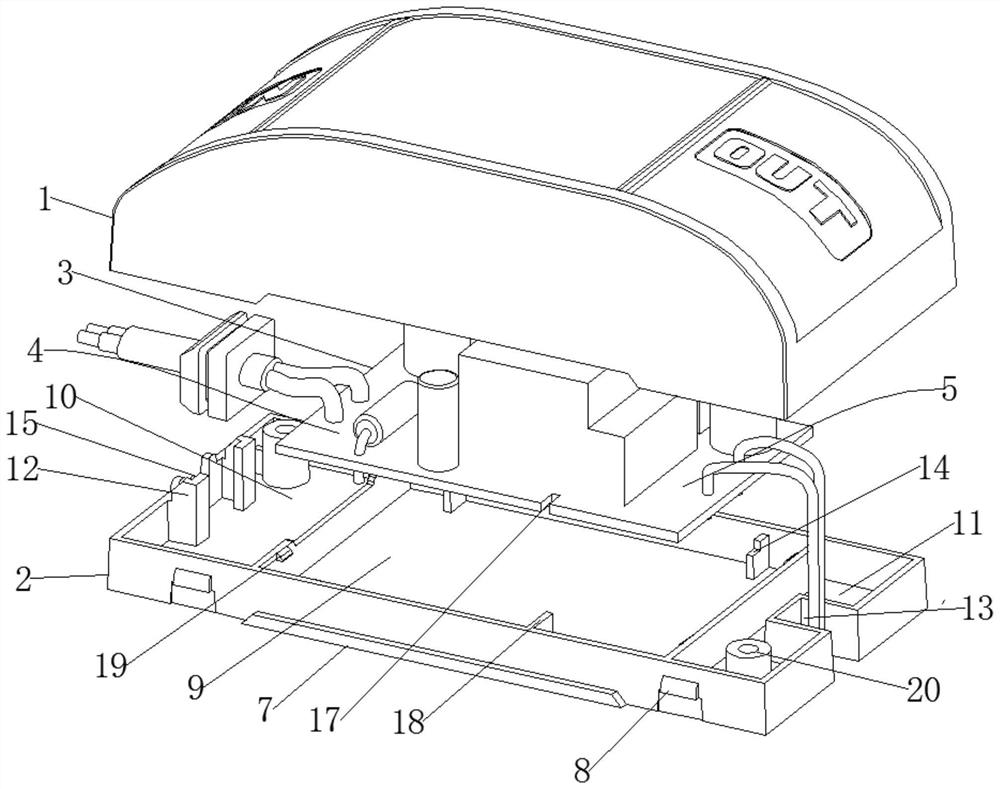

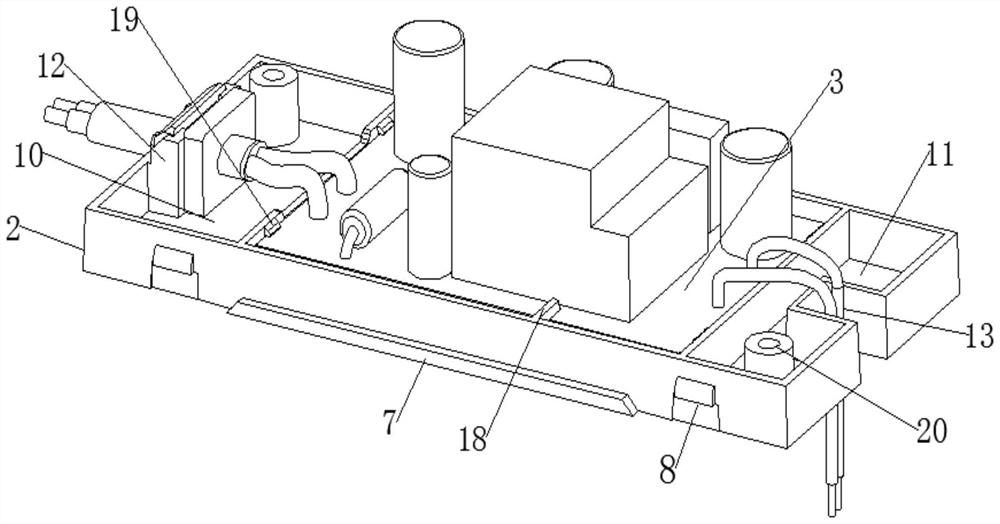

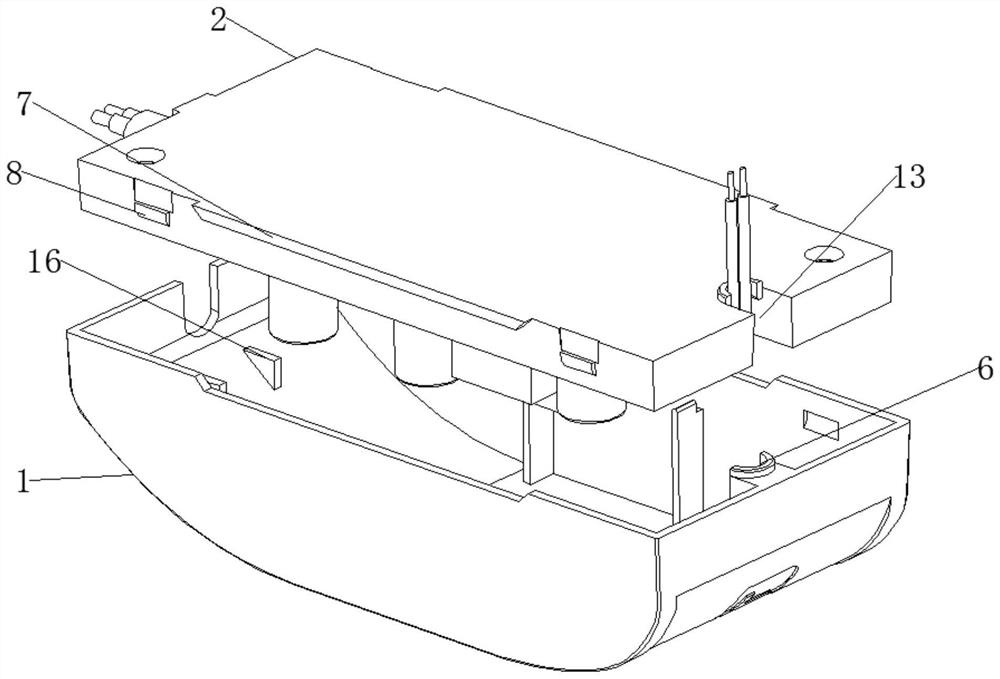

[0020] Figure 1-4 It shows a power supply fixing box disclosed by the present invention, which includes a box cover 1 and a box bottom 2, and also includes a PCB board 3 arranged between the box bottom 2 and the box cover 1, and the left and right sides of the PCB board 3 are respectively provided with input terminals 4 and the output terminal 5; the box cover 1 is provided with an output guide groove 6 corresponding to the output terminal 5; the box bottom 2 is provided with a positioning rib 7 and a positioning buckle 8 corresponding to the edge of the box cover 1, and a PCB groove 9 is provided in the middle of the box bottom 2; One side of the bottom of the box 2 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com