Cable cutter

A cable and driving device technology, applied in the field of cable cutters, can solve problems such as time-consuming, labor-intensive safety, internal complexity, and high transportation costs, and achieve the effects of saving operation and construction time, simple overall structure, and improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

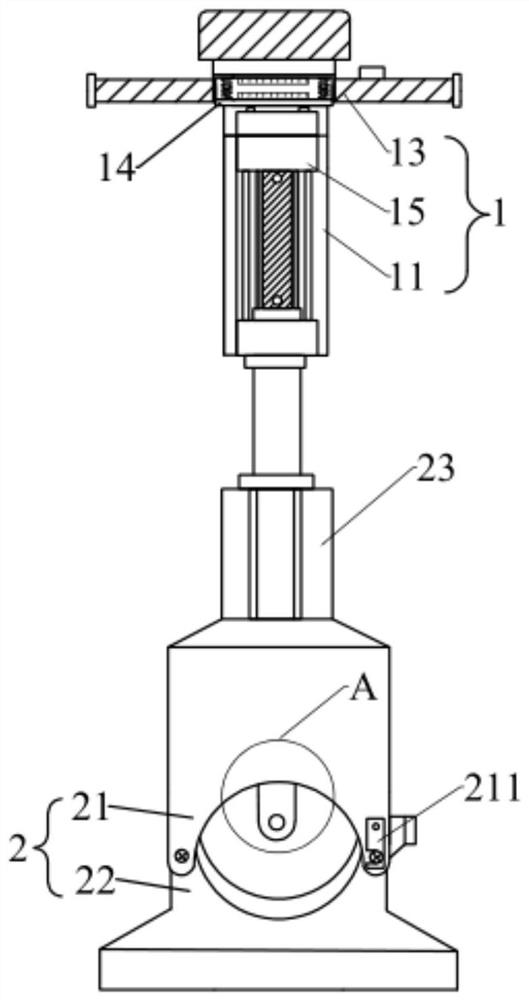

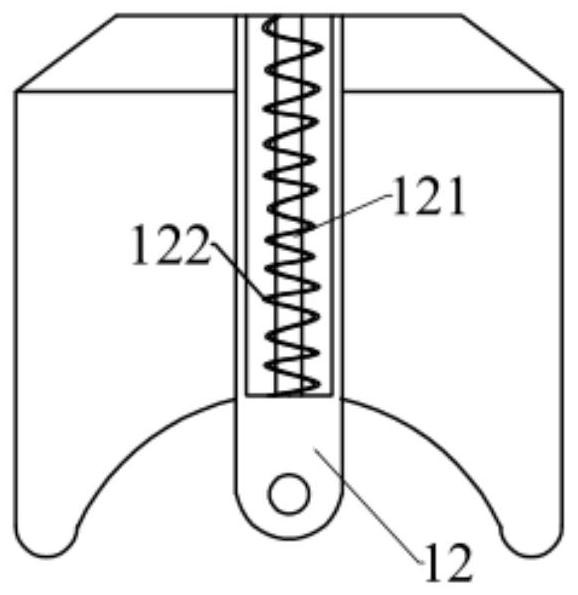

[0030] Such as Figure 1-Figure 2 As shown, the present invention provides a cable cutter, including a knife feeding mechanism 1 and a support 2, the knife feeding mechanism 1 includes a handle 13, a driving device 11 and a cutter 12, the handle 13 is installed on the driving device 11, and the driving Device 11 is provided with working end, and working end can move along vertical direction, and cutter 12 is installed on the working end; Driving device 11 is installed on the support 2, and support 2 comprises first support 21 and second support 22, and A support 21 is provided with a first installation groove, a second support 22 is provided with a second installation groove, one end of the first support 21 is rotationally connected with an end of the second support 22, and the other end of the first support 21 is provided with a lock Buckle 211, the lock buckle 211 can lock the other end of the first bracket 21 and the other end of the second bracket 22, so that the first ins...

Embodiment 2

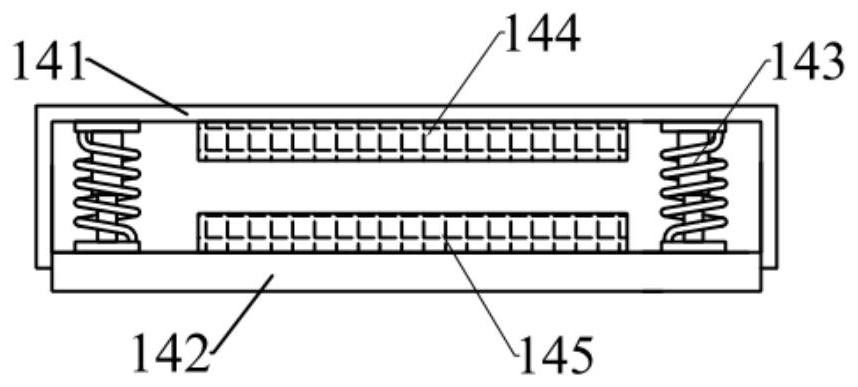

[0040] This embodiment provides a cable cutter, which is further improved on the basis of Embodiment 1. A shock absorbing device 14 is added to the knife feeding mechanism 1, which reduces the vibration and noise generated when the cable is cut, and reduces the noise. Shock device 14 such as image 3 shown.

[0041] Specifically, the knife feeding mechanism 1 also includes a shock absorber 14, and the shock absorber 14 includes a connecting block 141, a load bearing block 142 and a buffer portion 143, and the connecting block 141 is provided with a concave cavity with the opening facing downward, and the handle 13 is arranged on On both sides of the connection block 141, the load-bearing block 142 is fixedly installed on the driving device 11, the buffer portion 143 is located in the cavity, one end is connected to the connection block 141, and the other end is connected to the load-bearing block 142, and the load-bearing block 142 can be deformed in the concave cavity. Slidi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap