Method for preparing super absorbent polymer, and super absorbent polymer

A superabsorbent and polymer technology, applied in the field of superabsorbent polymers, can solve the problems of reduced absorption rate and absorption rate, increased internal crosslink density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

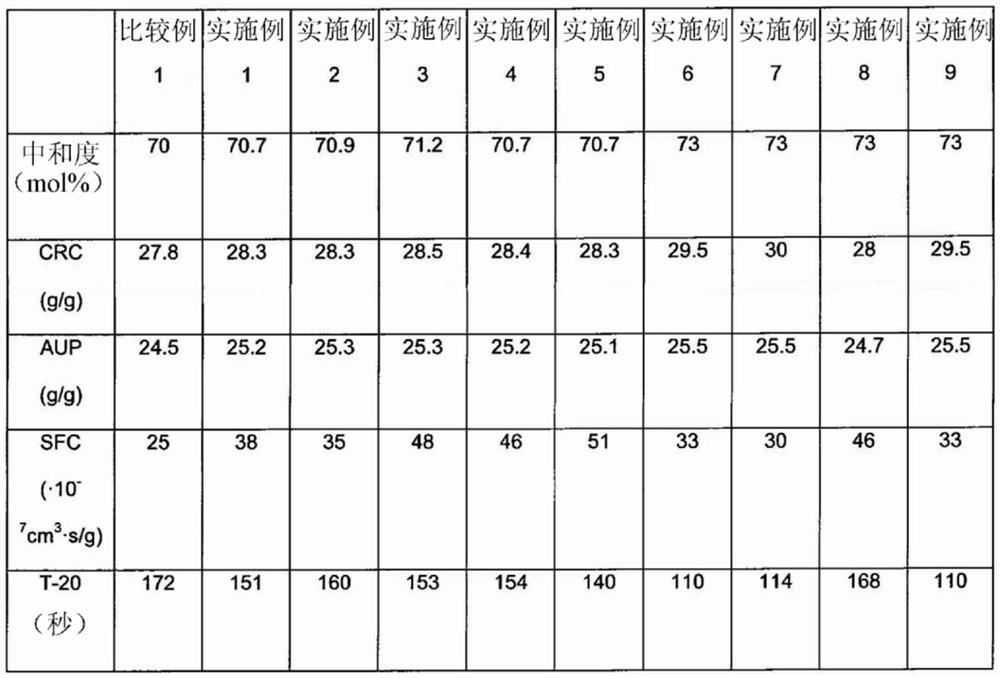

Examples

Embodiment 1

[0124] [Example 1]: Preparation of superabsorbent polymer

[0125] A base resin powder was prepared in the same manner as in Comparative Example 1, and a surface treatment process using ethylene carbonate was also performed in the same manner as in Comparative Example 1.

[0126] After the surface treatment, the temperature of the superabsorbent polymer was cooled to 90° C., and based on 100 g of superabsorbent polymer was mixed with 2.0 g of 5% by weight sodium hydroxide solution for an additional neutralization process.

[0127] Thereafter, the additionally neutralized superabsorbent polymer was dried in an oven at 40° C. for 30 minutes, and a surface-treated superabsorbent polymer having a particle diameter of 150 μm to 850 μm was obtained using a sieve. Fine powders with a particle size of less than 150 μm are contained in the superabsorbent polymer at less than 2% by weight.

Embodiment 2

[0128] [Example 2]: Preparation of superabsorbent polymer

[0129] A base resin powder was prepared in the same manner as in Comparative Example 1, and a surface treatment process using ethylene carbonate was also performed in the same manner as in Comparative Example 1.

[0130] After the surface treatment, the temperature of the superabsorbent polymer was cooled to 90° C., and based on 100 g of superabsorbent polymer was mixed with 10.0 g of 5% by weight sodium hydroxide solution for an additional neutralization process.

[0131] Thereafter, the additionally neutralized superabsorbent polymer was dried in an oven at 40° C. for 30 minutes, and a surface-treated superabsorbent polymer having a particle diameter of 150 μm to 850 μm was obtained using a sieve. Fine powders with a particle size of less than 150 μm are contained in the superabsorbent polymer at less than 2% by weight.

Embodiment 3

[0132] [Example 3]: Preparation of superabsorbent polymer

[0133] A base resin powder was prepared in the same manner as in Comparative Example 1, and a surface treatment process using ethylene carbonate was also performed in the same manner as in Comparative Example 1.

[0134] After the surface treatment, the temperature of the superabsorbent polymer was cooled to 90° C. and based on 100 g of superabsorbent polymer mixed with 20.0 g of 5% by weight sodium hydroxide solution for an additional neutralization process.

[0135] Thereafter, the additionally neutralized superabsorbent polymer was dried in an oven at 40° C. for 30 minutes, and a surface-treated superabsorbent polymer having a particle diameter of 150 μm to 850 μm was obtained using a sieve. Fine powders with a particle size of less than 150 μm are contained in the superabsorbent polymer at less than 2% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com