Method for producing super absorbent polymer, and super absorbent polymer

A superabsorbent, polymer technology, applied in the field of superabsorbent polymer and its preparation, can solve the problems of reduced efficiency, deterioration of physical properties of fine powder reassembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

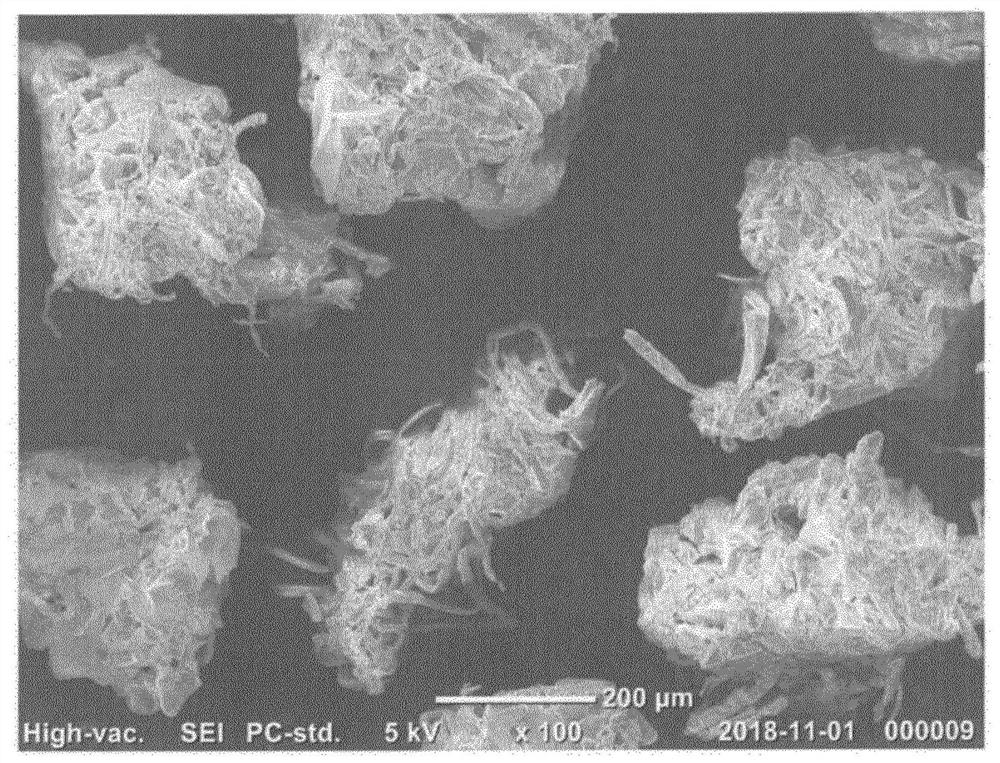

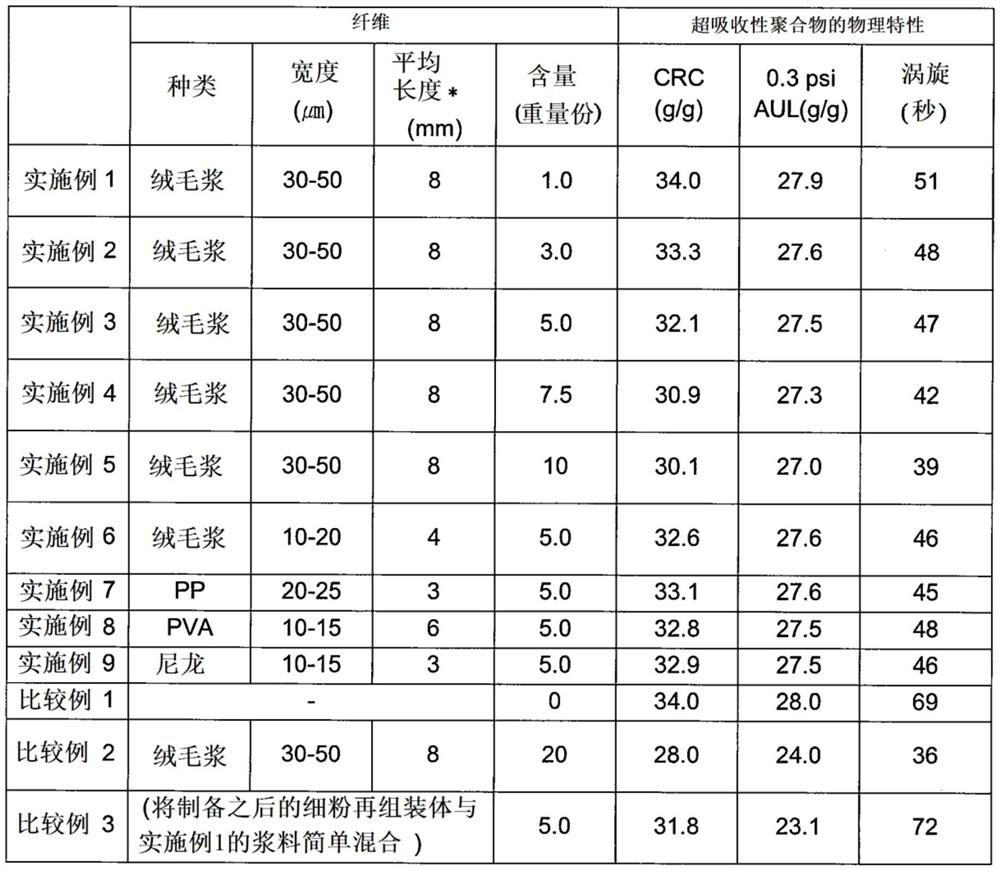

[0036] A method for preparing a superabsorbent polymer according to an embodiment of the present invention may include the step of performing thermal polymerization or photopolymerization of a monomer composition comprising a water-soluble ethylenically unsaturated monomer and a polymerization initiator to prepare a water-containing the gel polymer; the aqueous gel polymer is dried, pulverized and size-sorted to classify the aqueous gel polymer into fine powder with a particle size of less than 150 μm and regular particles with a particle size of 150 μm to 850 μm; one or more of the fluff pulp and the synthetic polymer fibers are mixed with the fine powder and water to prepare an aqueous fine powder solution; and the aqueous fine powder solution is agitated to prepare a fine powder reassembly.

[0037] For reference, as used herein, "polymer" means a polymerized state of a water-soluble ethylenically unsaturated monomer, and may encompass polymers in all water content ranges, p...

preparation example 1

[0116] 100g of acrylic acid, 3.0g of polyethylene glycol diacrylate (PEGDA, Mw=523) as a crosslinking agent, 0.008g of phenylbis(2,4,6-trimethylbenzoyl) as a photoinitiator Phosphine oxide, 0.08 g of sodium persulfate (SPS) as a thermal initiator, 128 g of caustic soda (NaOH) and 63.5 g of water were mixed with each other. To this mixture, each fiber in Table 1 below was added in an amount of 5 parts by weight relative to 100 parts by weight of the monomer composition to prepare a monomer composition.

[0117] Thereafter, the monomer composition was placed on a continuously moving conveyor belt and irradiated by UV (UV intensity: 2mW / cm 2 ) was UV polymerized for 2 minutes to obtain an aqueous gel polymer sheet.

[0118] The aqueous gel polymer sheet was cut into a size of 3 cm x 3 cm and minced using a meat grinder (hole size 16 mm, speed 60 Hz) to prepare crumbs. The chips are dried in an oven capable of moving the air flow up and down. Specifically, the chips were unifor...

Embodiment 1 to 9

[0121] (1) Preparation of fine powder reassembled body

[0122] Each fiber of Table 1 below was added in an amount as described in Table 1 with respect to 100 parts by weight of the fine powder having a particle size of less than 150 μm obtained in Preparation Example 1, and allowed to mix with each other for 1 minute. Then, 150 parts by weight of water was added, and further mixed for 10 seconds to prepare a fine powder reassembled body.

[0123] (2) Preparation of Superabsorbent Polymer Containing Fine Powder Reassembled Body

[0124] The hydrous gel polymer minced using a meat grinder (hole size: 16 mm) and the fine powder reassembled body in Preparation Example 1 were mixed in a weight ratio of 75:25 to obtain a coarsely pulverized hydrous gel polymer . Thereafter, the steps of drying, pulverization and size classification were performed in the same manner as in Preparation Example 1 to prepare a base polymer.

[0125] Thereafter, a surface crosslinking solution (6.2 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com