Cathode active material for lithium secondary battery, production method therefor, cathode comprising same for lithium secondary battery, and lithium secondary battery comprising same

A cathode active material, lithium secondary battery technology, used in secondary batteries, electrode manufacturing, battery electrodes, etc., can solve problems such as the decline of discharge capacity and output characteristics, achieve excellent output characteristics, reduce manufacturing costs, and improve structural stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] In the preparation of the positive electrode active material precursor, it is possible to control the pH in such a manner that it decreases as the nickel content in the mixed solution decreases.

[0082] For example, the pH may gradually decrease within the range of 13 to 9, preferably 12.5 to 9, most preferably 12 to 10 as the nickel content in the mixed solution decreases. In the case of controlling the gradual decrease in pH as the nickel content decreases during the preparation of the cathode active material precursor as described above, the c-axis direction on the surface of the finally prepared cathode active material particle can be effectively controlled.

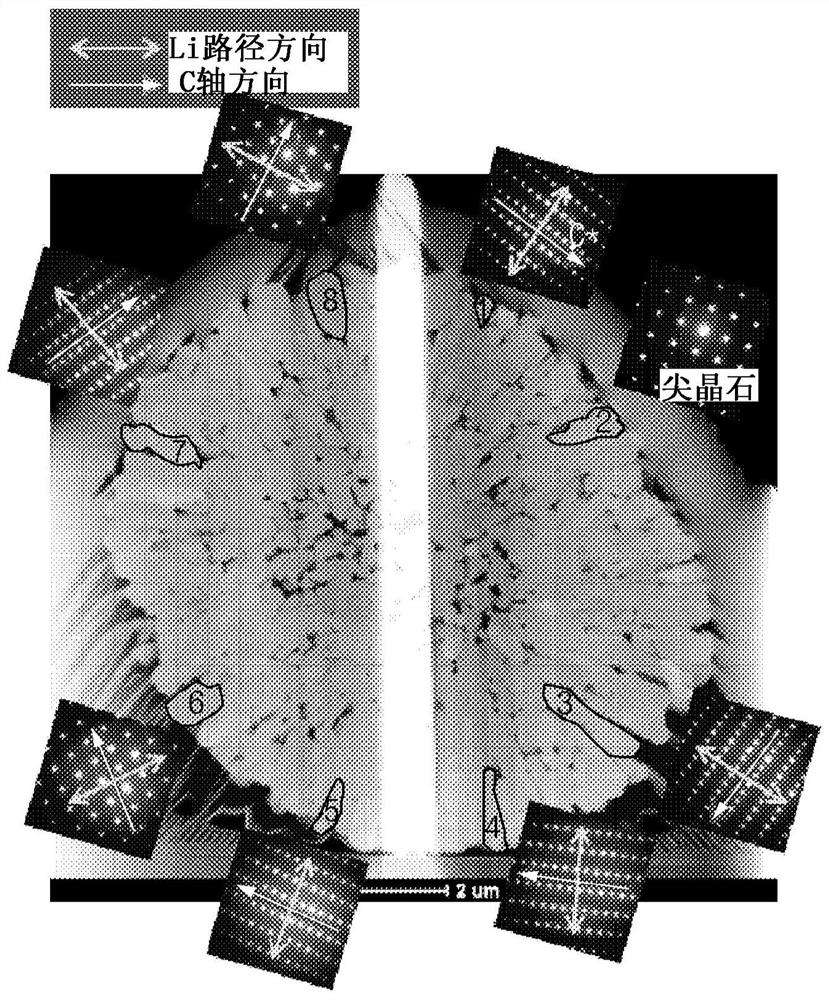

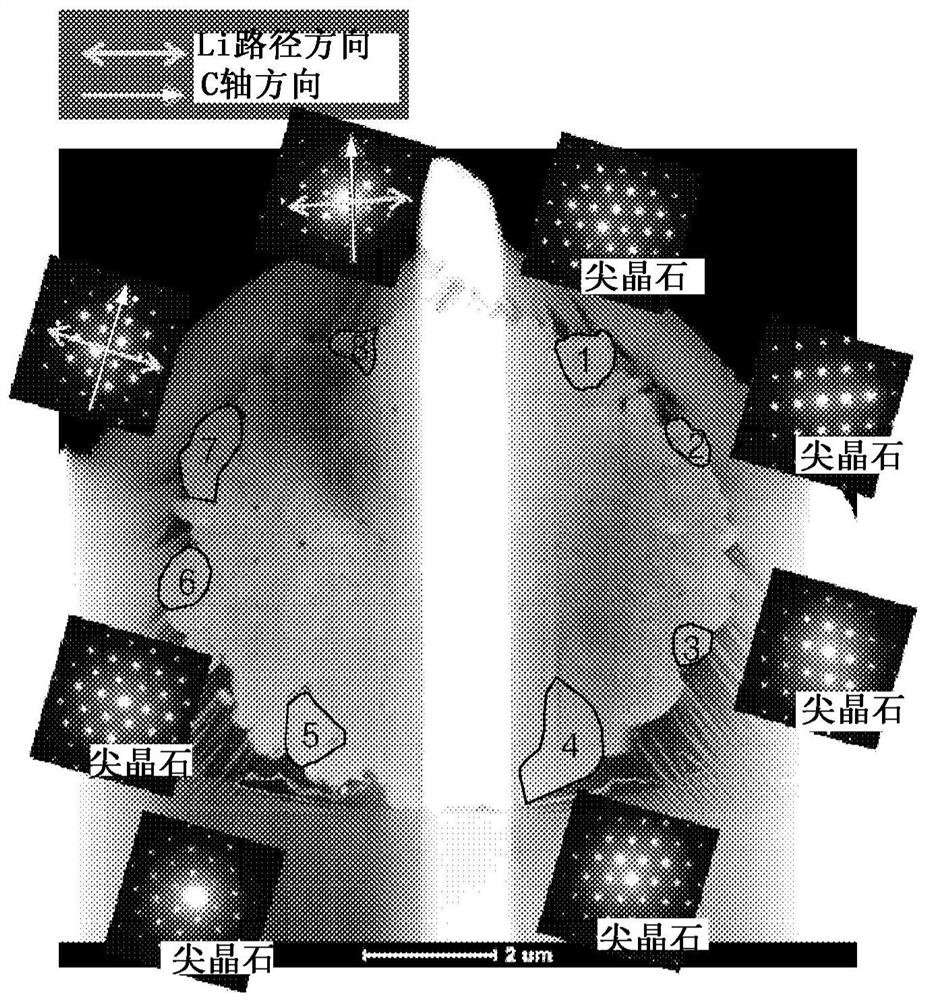

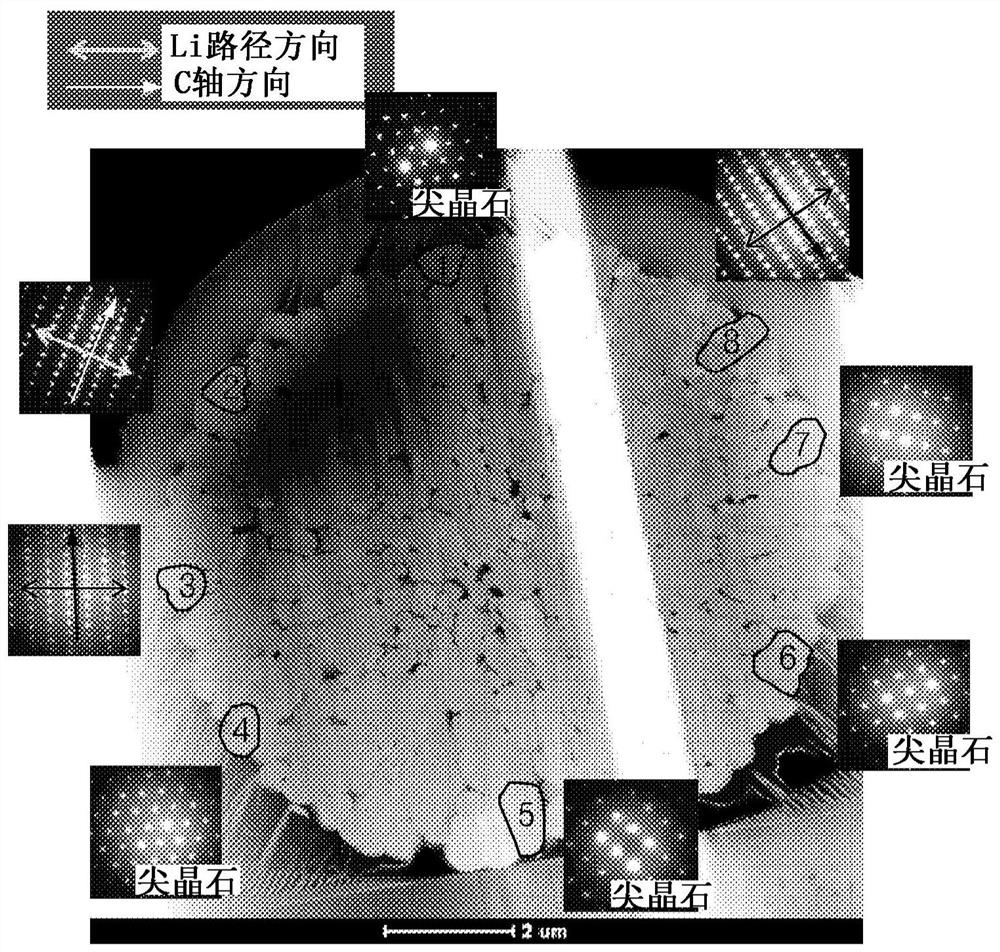

[0083] Specifically, at least 8 points on the surface of the positive electrode active material, the angle between the c-axis direction measured by TEM analysis and the growth direction at the measurement point satisfies a ratio of 85° to 95° as More than 60% of the way to form the positive electrode active m...

Embodiment approach

[0133] Hereinafter, the present invention will be described in detail based on specific examples. This invention may, however, be embodied in many different forms and should not be construed as limited to the embodiments set forth herein. Rather, these example embodiments are provided so that this description will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art.

Embodiment 1

[0136] (Preparation of positive electrode active material)

[0137] By adding NiSO in such an amount that the nickel:manganese molar ratio 4 and MnSO 4 Mix in water to prepare a first transition metal-containing solution at a concentration of 2.3M.

[0138] In addition, by adding NiSO 4 、CoSO 4 and MnSO 4 Mix in water to prepare a second transition metal-containing solution at a concentration of 2.3M.

[0139] The vessel containing the first transition metal-containing solution and the vessel containing the second transition metal-containing solution were connected to a 250 L reactor set at 53°C. Alternatively, prepare a solution of 25% NaOH and 15% NH 4 OH aqueous solution and connect it to the reactor separately.

[0140] Subsequently, 55 L of deionized water was put into the reactor, and then the reactor was purged with nitrogen gas at a rate of 200 L / min to remove dissolved oxygen in the water and create a non-oxidative atmosphere in the reactor. Thereafter, 50 mL ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap