Veneer pasting device for furniture production

A technology for laminating and furniture, applied in the field of furniture, can solve problems such as uneven lamination, avoid clamping damage and increase work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

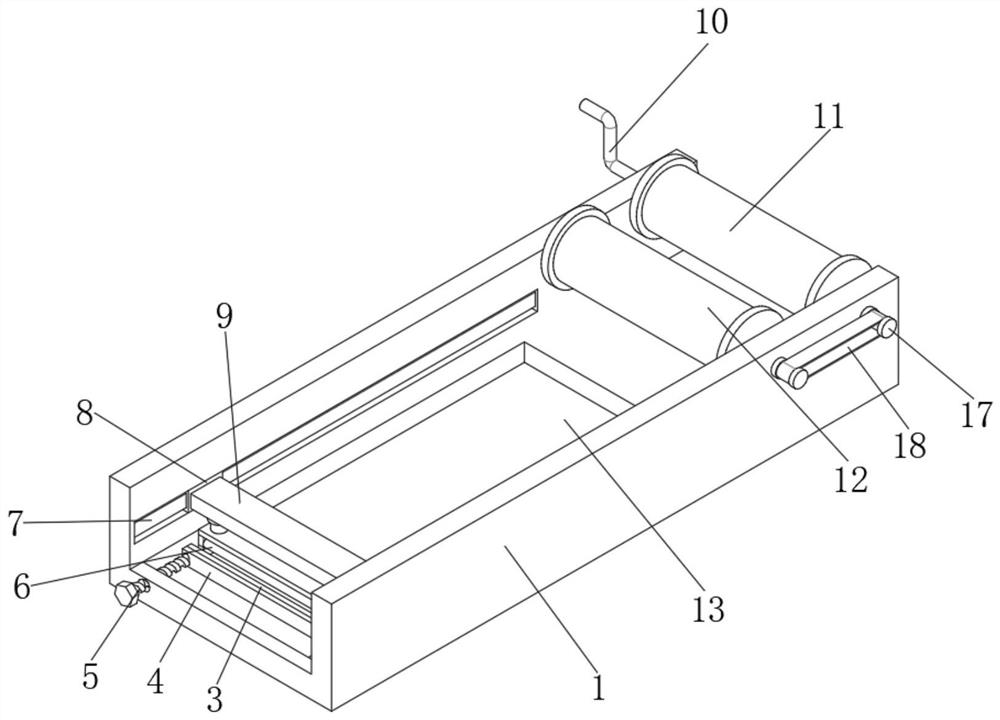

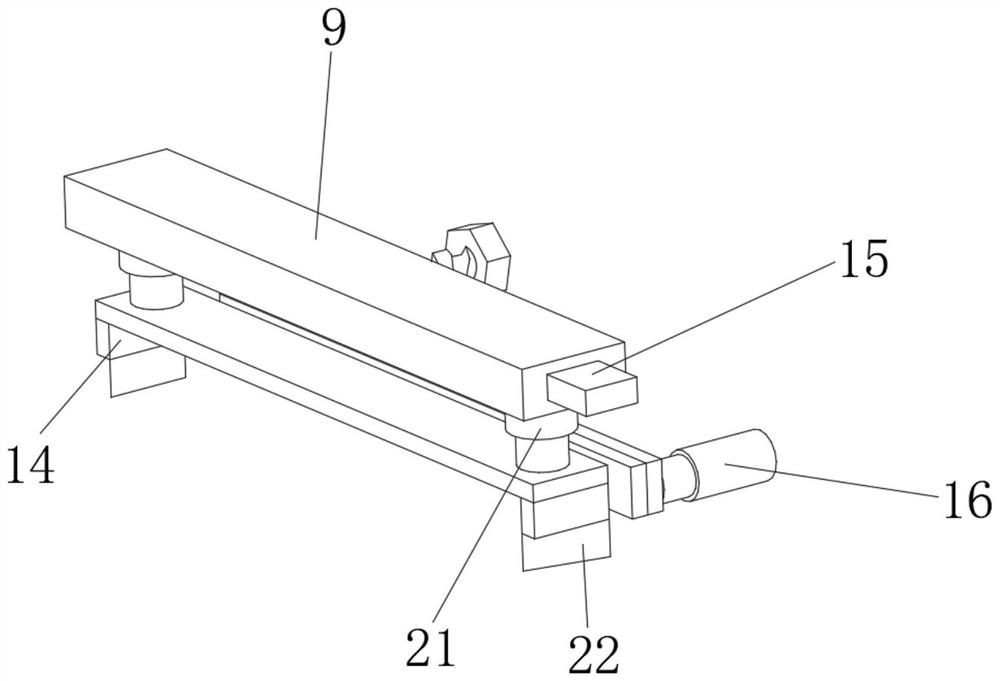

[0023] refer to Figure 1-2 , a skinning device for furniture production, comprising a base 1, a first chute is opened on one side of the inner wall of the base 1, and an electric slide rail 7 is connected to the two inner walls of the first chute by bolts, and the electric slide rail 7 An electric slider 8 is slidably connected to the outer walls around, and one side outer wall of the electric slider 8 is connected with a connecting plate 9 by bolts, and the inner wall of one side of the base 1 is provided with a second chute, and the inner wall of the second chute is slidably connected with a Slider 15, the outer wall of the opposite side of slider 15 and electric slider 8 is connected with the same connecting plate 9 by bolts, and the bottom outer wall of connecting plate 9 is connected with two electric push rods 21 by bolts, two electric push rods The piston rod of 21 is connected with the same U-shaped plate 14 by bolts, and the opposite side inner wall of the U-shaped p...

Embodiment 2

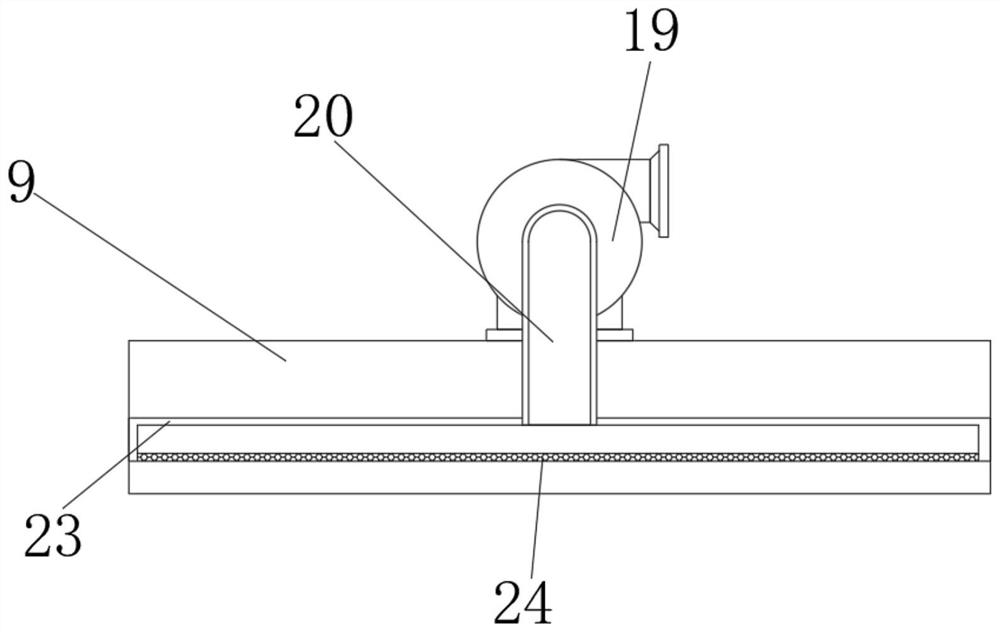

[0031] refer to Figure 1-3 , a skinning device for furniture production, also includes a hot air blower 19 connected to the top outer wall of the connecting plate 9 by bolts, and the exhaust end of the hot air blower 19 is connected with an air outlet pipe 20 by bolts, and one end of the air outlet pipe 20 passes through A gas collecting box 23 is connected by bolts, and a plurality of leakage holes 24 are arranged on the bottom outer wall of the gas collecting box 23 .

[0032] Working principle: During skin lamination, the hot air generated by the hot air blower 19 dries the film through the gas collecting box 23, so as to ensure that the film is quickly bonded to the furniture board and achieve the purpose of increasing work efficiency.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap