Linear Compressor Magnetic Barrel Processing Method

A technology of linear compressors and processing methods, which is applied in the production field of compressor components, can solve problems such as uneven stress distribution, poor consistency and uniformity, and increase manufacturing costs, and achieve good consistency and uniformity and ensure uniform thickness Sexuality and the effect of reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the examples.

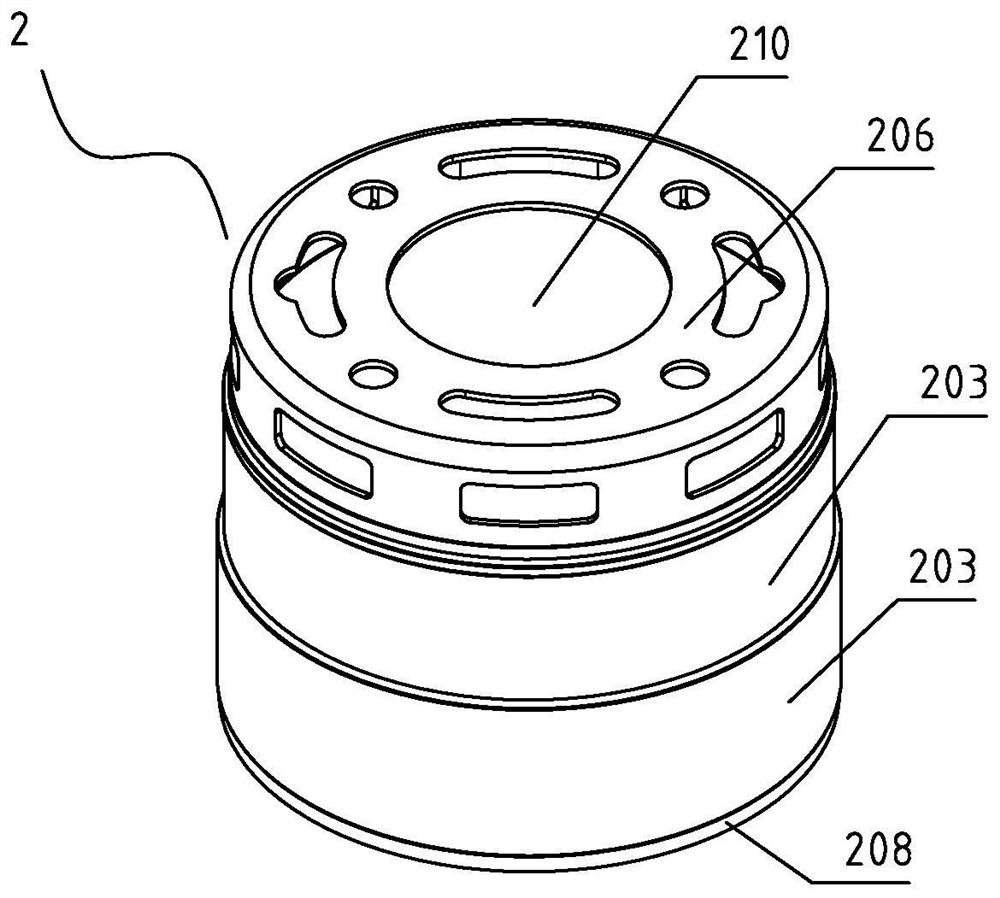

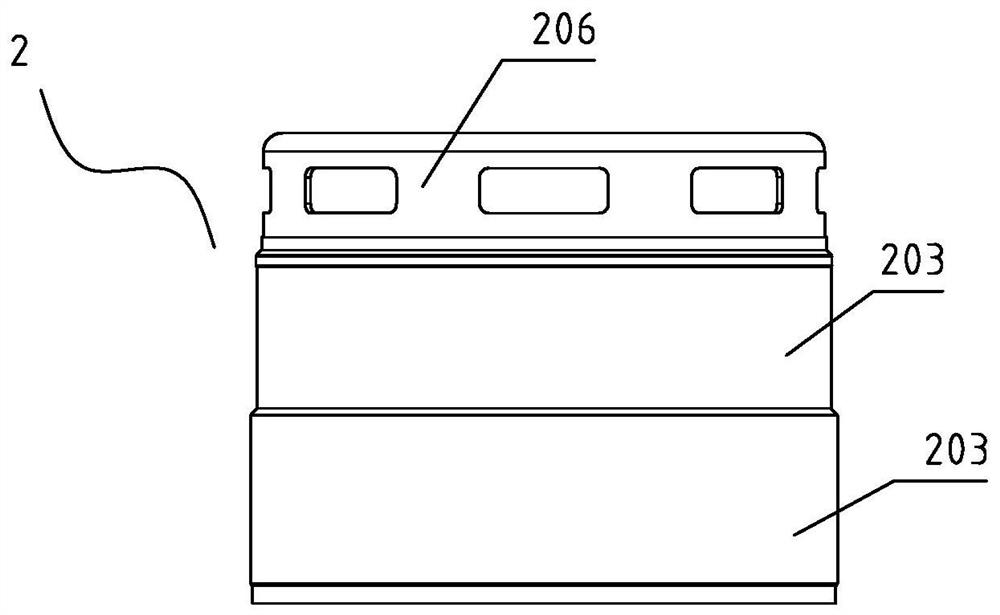

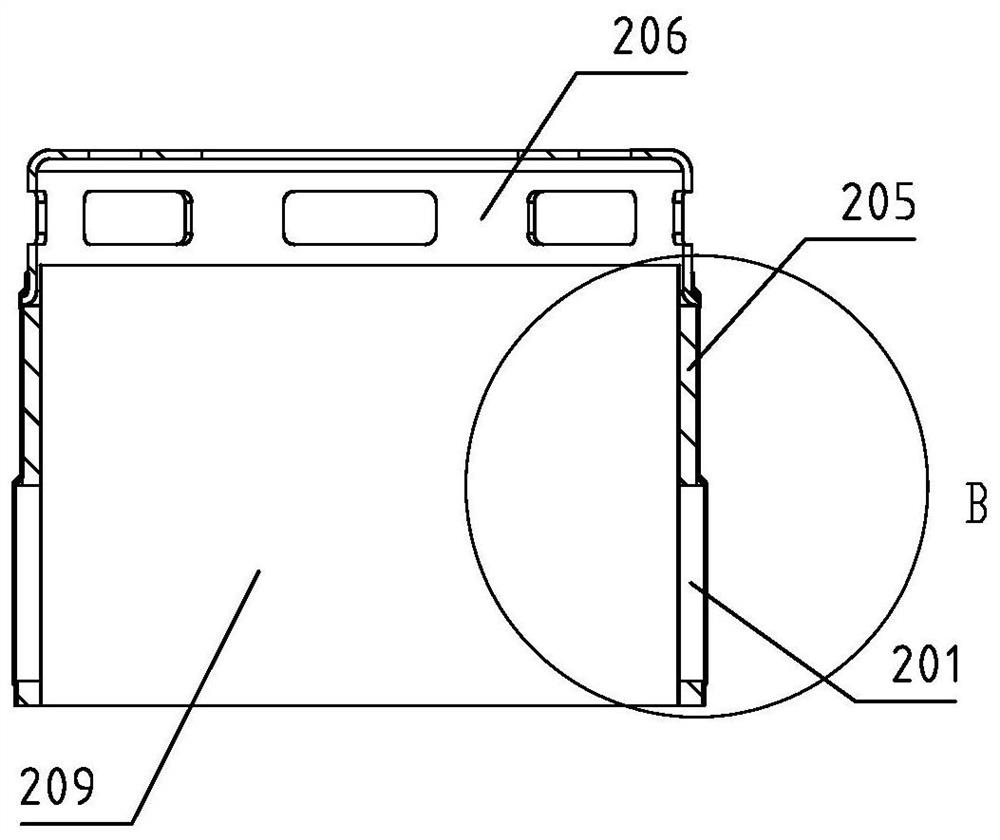

[0051] Figure 1-Figure 18 It is an embodiment of a linear compressor magnetic barrel processing method of the present invention, comprising the following steps:

[0052] (1) Prepare the tooling 1 for making the magnetic barrel of the linear compressor, set the ejector sleeve 102 on the outer surface of the winding part 108, and place the ejector sleeve 102 and the tooling 1 for the magnetic barrel of the linear compressor on the outer surface of the winding part 108. Apply mold release agent on the surface, then heat in the oven;

[0053] (2) Winding the inner layer prepreg 202 on the outer surface of the winding part 108;

[0054] (3) Set the permanent magnet end positioning sleeve 204 on the outer surface of the inner layer prepreg 202, and set the permanent magnet end positioning sleeve 204 at the bottom position of the manufacturing tooling 1, which is located at the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com