Paint consumption prediction

A technology that consumes materials and computers, applied in the field of prospective maintenance, can solve problems such as the advantages of undisclosed big data applications put into use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

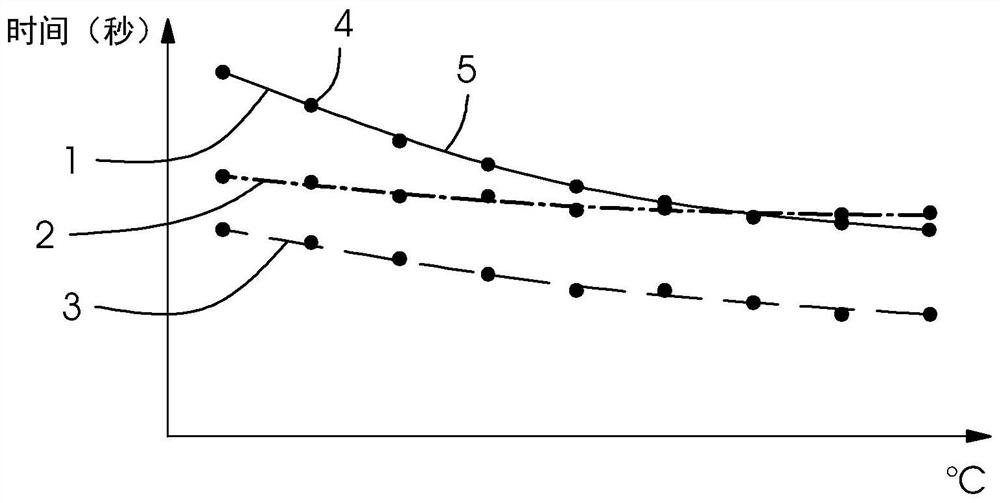

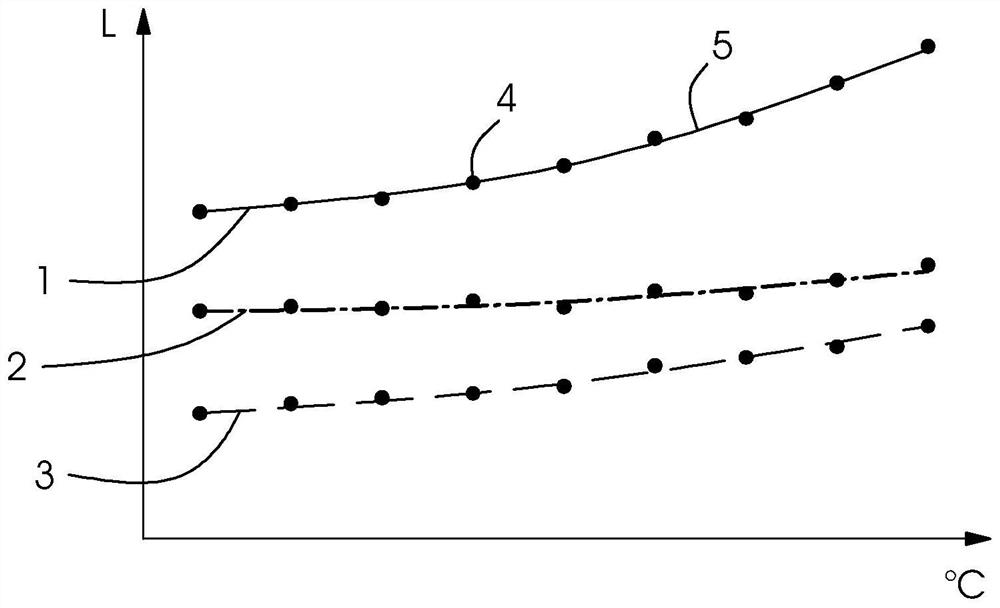

[0022] The invention assumes that, on the one hand, relevant data from the prepress stage (Druckvorstufe) regarding the parameters of the corresponding printing job and, on the other hand, from warehouse management regarding fluid consumables (mainly varnishes, but also inks or Wetting agent) removal data are processed in order to generate accurate consumption models.

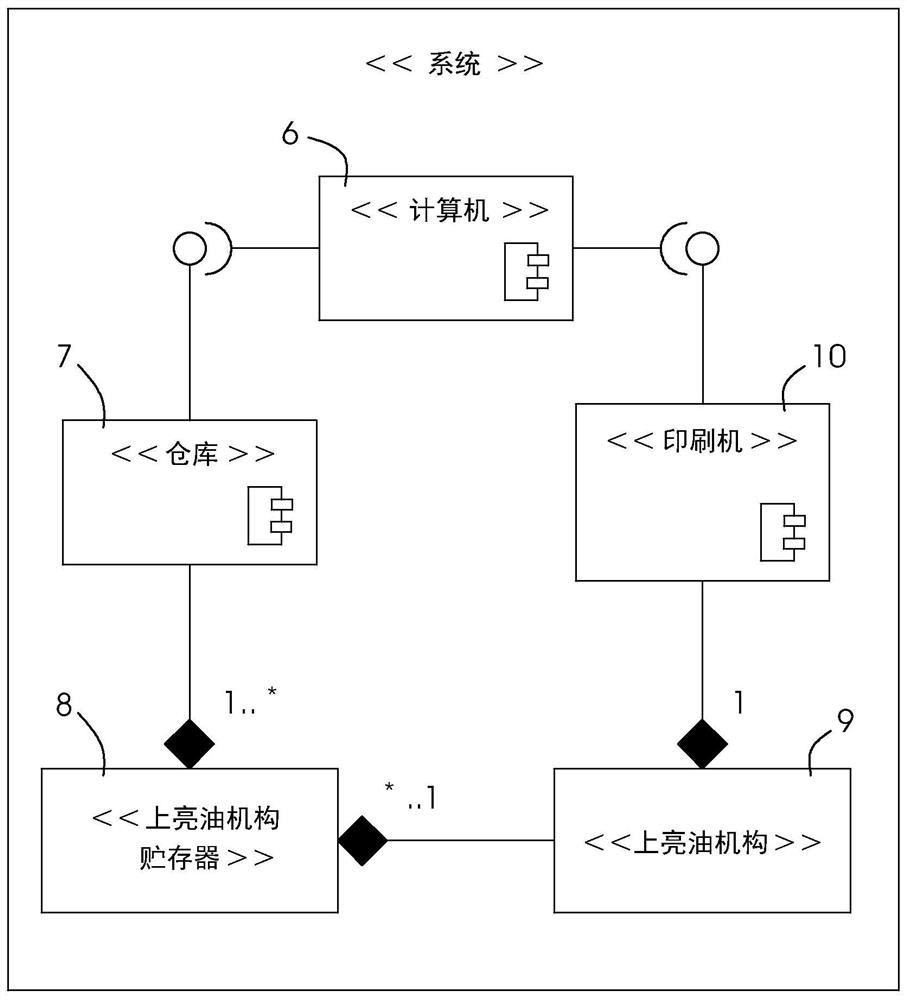

[0023] image 3 The structure of the logistics system between the printing press 10 and the warehouse 7 is schematically shown. The computer 6 , which has access to the data of all the components involved, checks here all relevant consumption data and warehouse data of the printing press 10 used. In the case of varnish as fluid consumable material, the varnish is applied in the varnishing unit 9 of the printing press 10 . If the reserve is exhausted, another bright oil reservoir 8 must be provided from the warehouse 7 in order to replenish the reserve of the bright oil device 9 accordingly. The varnish consu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com