Counter-rotating fan structure

A counter-rotating and fan technology, applied in the direction of non-volume pumps, non-variable pumps, electrical equipment structural parts, etc., can solve problems such as poor structural configuration design, influence of fan air outlet efficiency, and negative effects , to achieve the effect of improving characteristic performance, enhancing characteristic performance, and enhancing heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

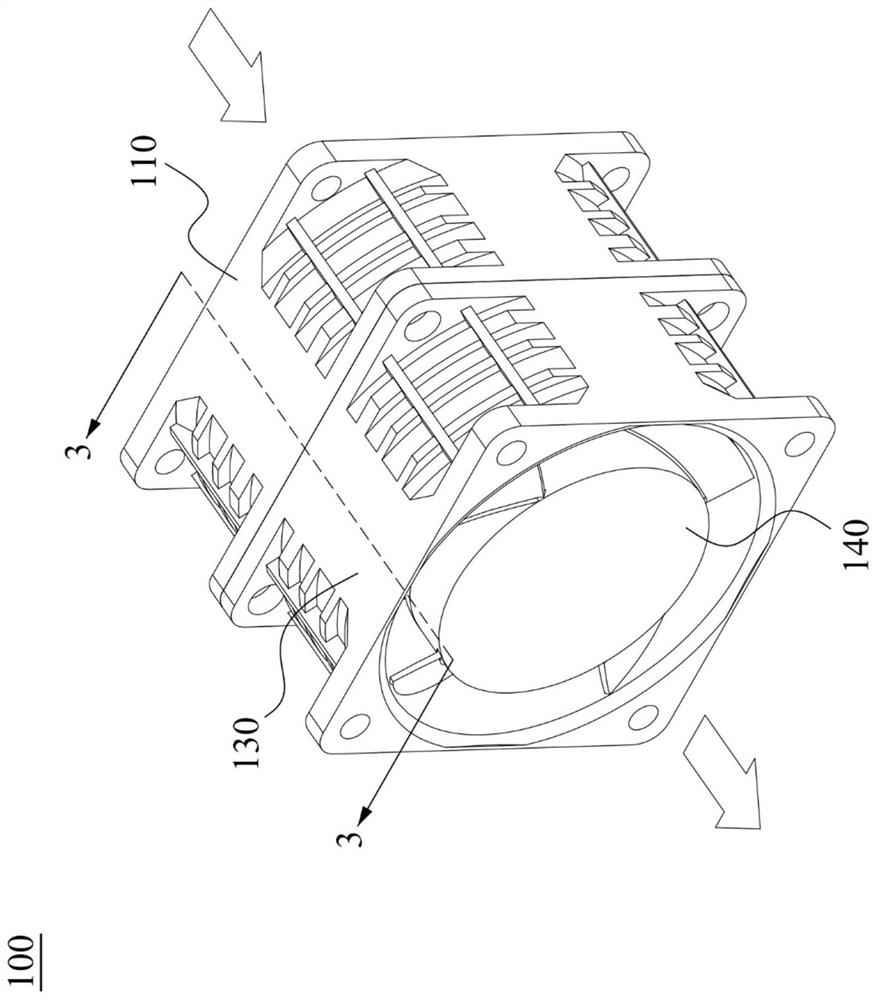

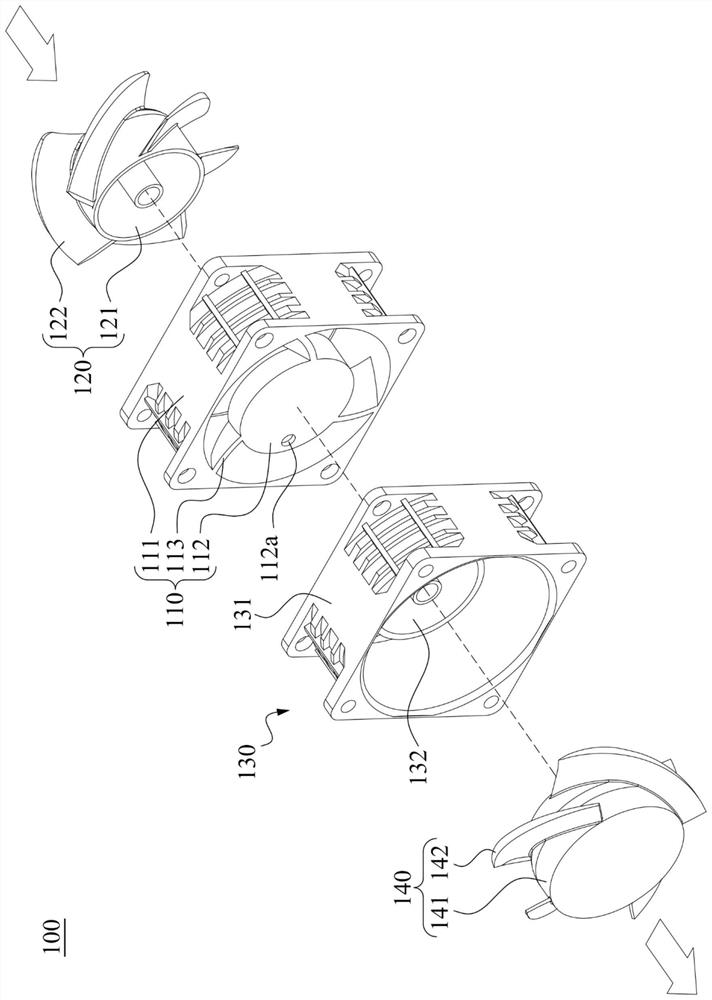

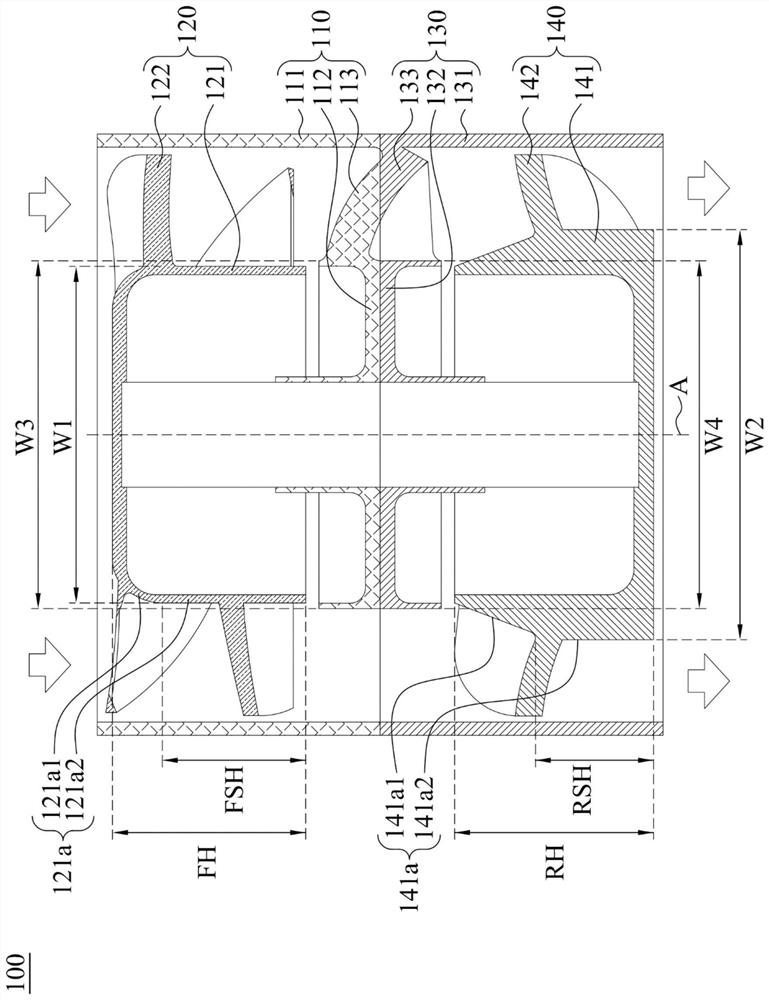

[0058] Please refer to Figure 1 to 3 . figure 1 To draw a stereo combination diagram of the swirl fan structure 100 according to an embodiment of the present invention. figure 2 To draw figure 1 The stereoscopic explosive diagram of the spin type fan structure 100. image 3 To draw figure 1 A cross-sectional view of the inverse fan structure 100 along the line segment 3-3. Figure 1 to 3 The direction of arrows represented is to indicate the direction of the spin fan. like figure 1 and figure 2 As shown in the present embodiment, the swirl fan structure 100 includes a first housing 110, a first fan 120, a second housing 130, and a second fan 140. The connection relationship between the components contained in the rotary fan structure 100 will be described in detail below.

[0059] like figure 2 As shown in the present embodiment, the first housing 110 includes a first outer wall 111, a first base 112, and a plurality of first calibration blades 113. The first outer wall 111 has a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com