Self-cleaning detection method of range hood based on DC motor drive

A range hood and DC motor technology, which is applied in the fields of oil fume removal, heating method, household stove/stove, etc., can solve the problems of high hardware installation cost, high cost, and high power consumption, so as to solve the problem of inaccuracy and reduce the The effect of energy consumption and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

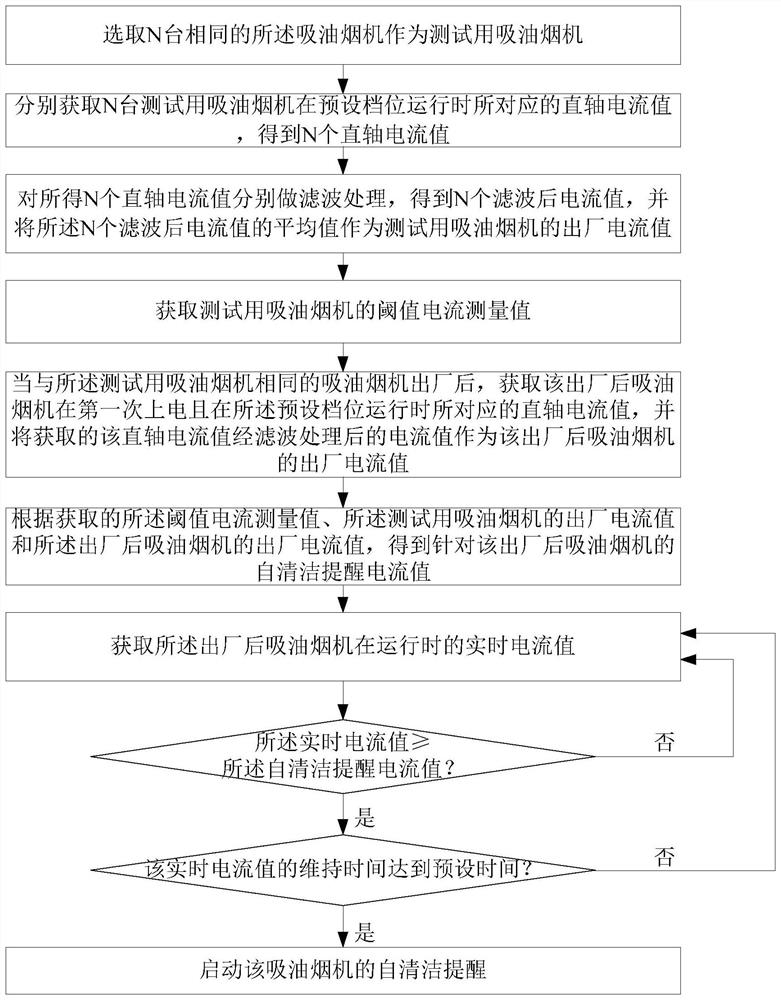

[0036] see figure 1 As shown, this embodiment provides a self-cleaning detection method for a range hood driven by a DC motor. The self-cleaning detection method for a range hood includes the following steps 1 to 8:

[0037] Step 1, select N identical range hoods as test range hoods; wherein, N≥1; for example, select 10 identical range hoods in this embodiment, that is, set N=10;

[0038] Step 2, respectively obtain the direct-axis current values corresponding to N sets of test range hoods operating in preset gears, and obtain N direct-axis current values; wherein, the i-th test range hood is in the preset The corresponding direct-axis current value during gear operation is marked as Id(i), 1≤i≤N; in addition, the term "direct-axis current" belongs to the common knowledge of those skilled in the art, and will not be repeated here;

[0039]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com