Water vapor detection, sampling and cooling tank

A cooling tank and water vapor technology, applied in sampling devices, measuring devices, instruments, etc., can solve problems such as difficulty in ensuring the circumferential sealing of the interface, loose air intake pipes, and popping out of the outer ring of the seal, so as to improve work efficiency and service life. Guaranteed sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

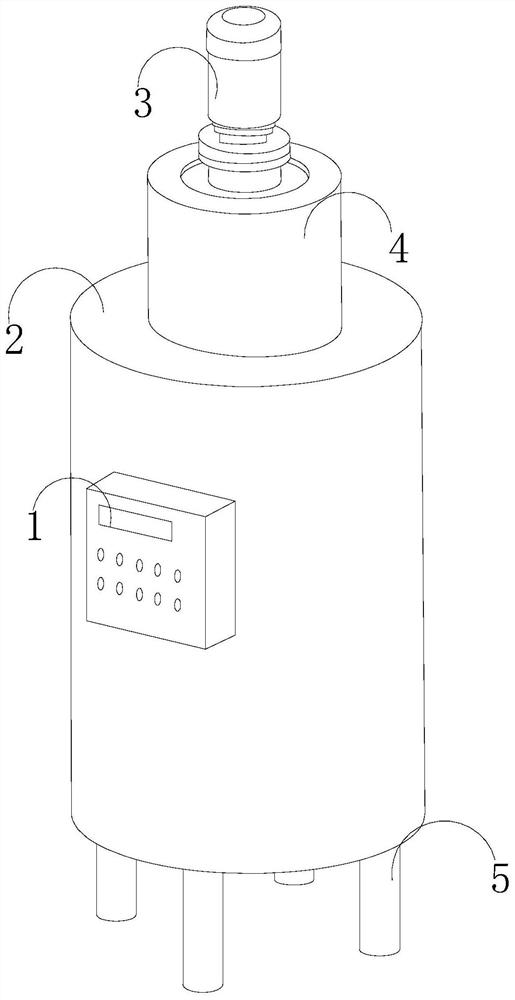

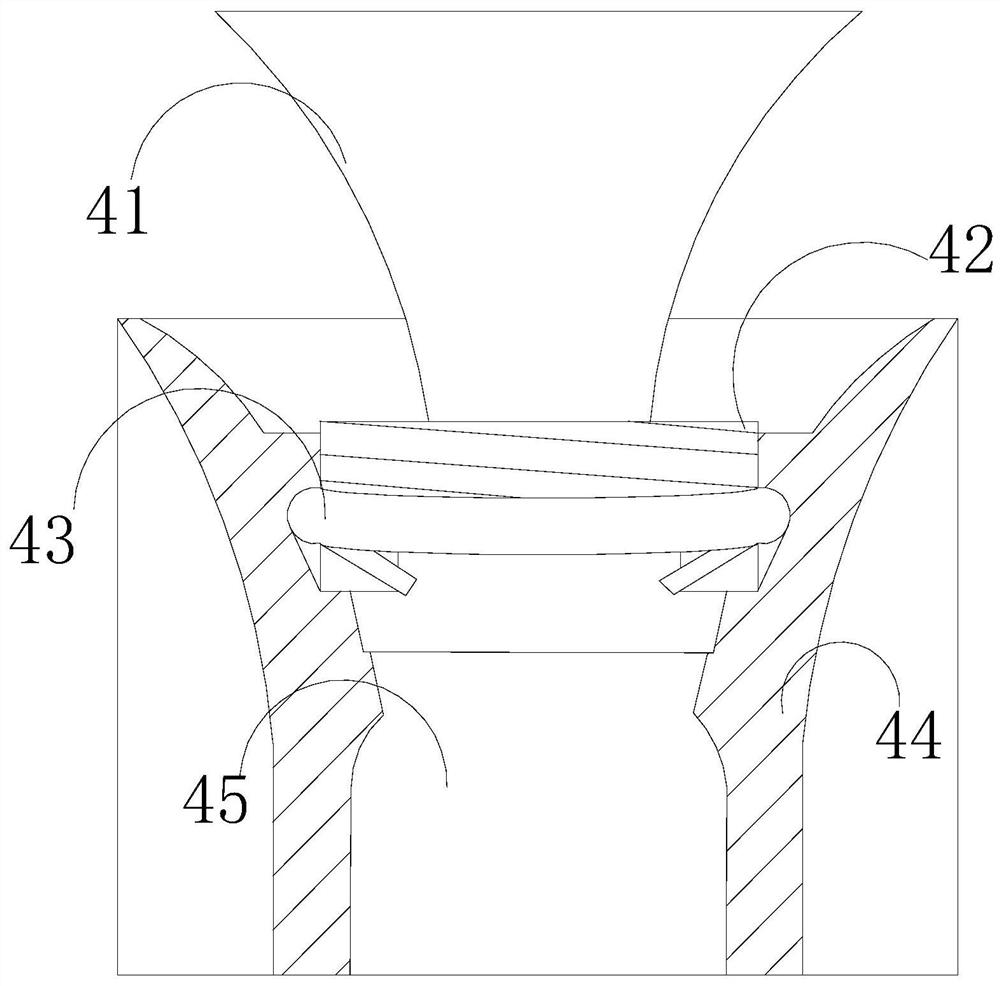

[0030] Such as Figure 1-Figure 4 As shown, the present invention provides a water vapor detection sampling cooling tank, the structure of which includes a control panel 1, a cooling host 2, a motor 3, a sampling introduction structure 4, and a support bracket 5. The control panel 1 is fixedly connected to the outer surface of the cooling host 2 , and the four corners of its bottom are welded to connect with support Jiao 5, and its top is equipped with a sampling introduction structure 4, and the bottom of the sampling introduction structure 4 extends to the inside of the cooling host 2, and is electrically connected with the motor 3, and the sampling introduction structure 4 includes Funnel inlet 41, air inlet pipe 42, top support structure 43, tank mouth 44, container mouth 45, described funnel inlet 41 is fixed with the inside of air inlet pipe 42, described air inlet pipe 42 and tank mouth 44 adopt the mode of threaded connection, two The supporting structure 43 is install...

Embodiment 2

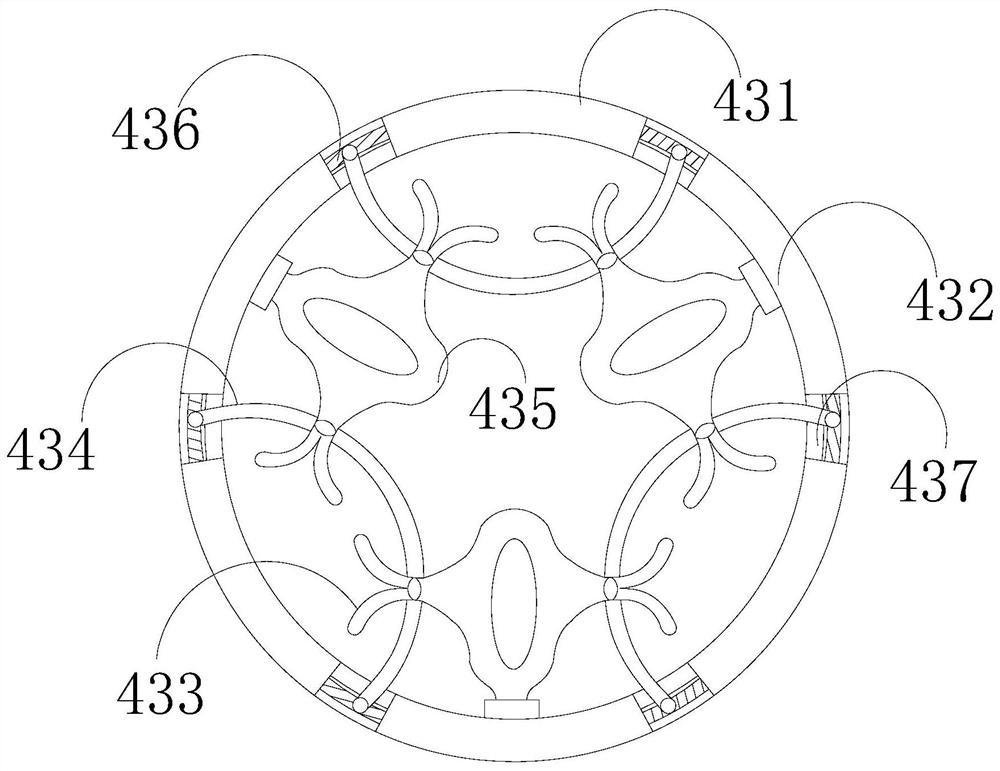

[0032] Such as Figure 5-Figure 7As shown, on the basis of Embodiment 1, the present invention combines the mutual cooperation of the following structural components. The limiting structure 436 includes a support plate 361, a rotating shaft 362, an intermediate piece 363, an expansion spring 364, and a positioning structure 365. The supporting plate 361 is arranged between the expansion spring 364 and the positioning structure 365, and the middle part of the expansion spring 364 is fixed with a rotating shaft 362. , the middle part of the middle part 363 is clearance-fitted on the periphery of the sealing part 437, the positioning structure 365 includes a running-in part 5a1, a crescent plate 5a2, a connecting frame 5a3, and a reinforcing chute 5a4, and the running-in part 5a1 is installed on the reinforcing chute 5a4 In between, two ends of the reinforcement chute 5a4 are fixedly connected with a connecting frame 5a3, and two crescent plates 5a2 are arranged symmetrically ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com