Drawing test device for processing of nylon heat insulation strip

A nylon heat-insulating strip, pull-out testing technology, applied in measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the problems of troublesome testing, unrepresentative, single function, etc. Convenience, perfect measurement data, and the effect of diversifying test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

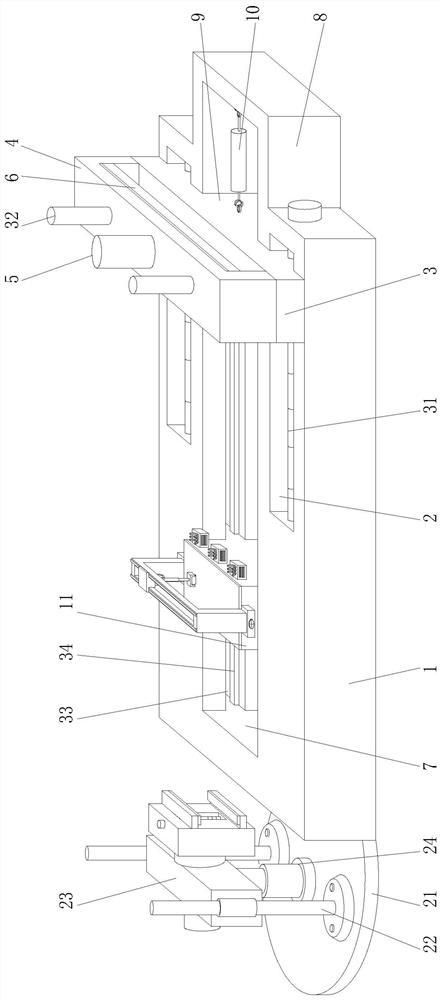

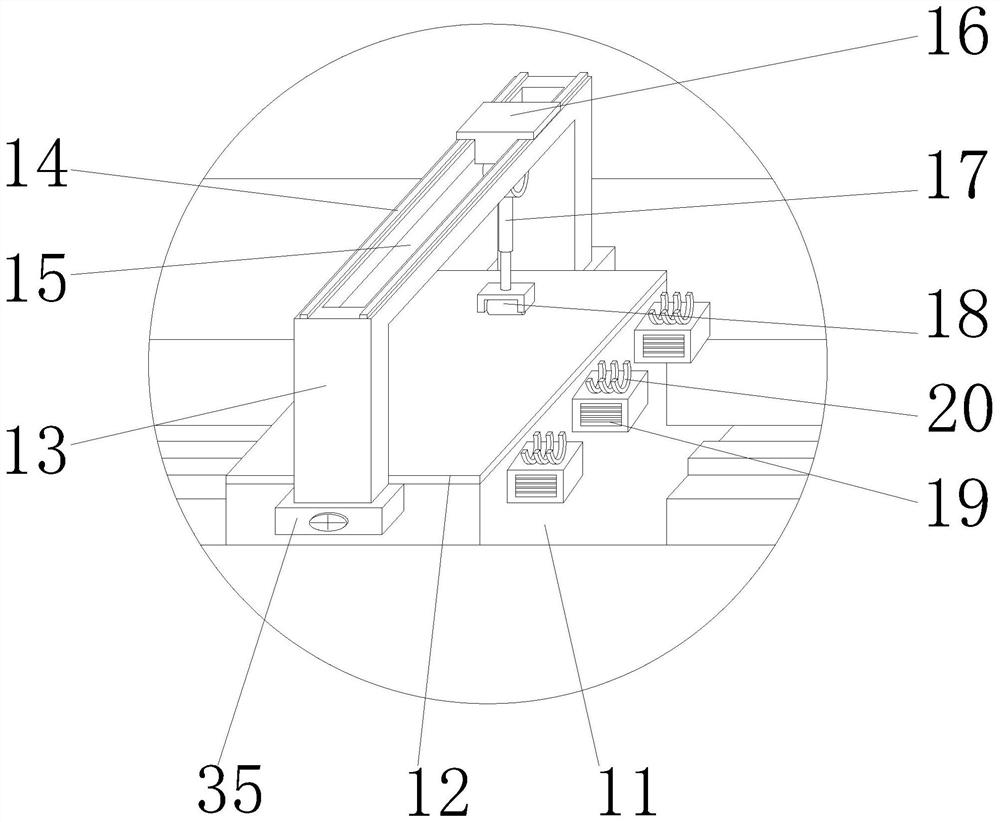

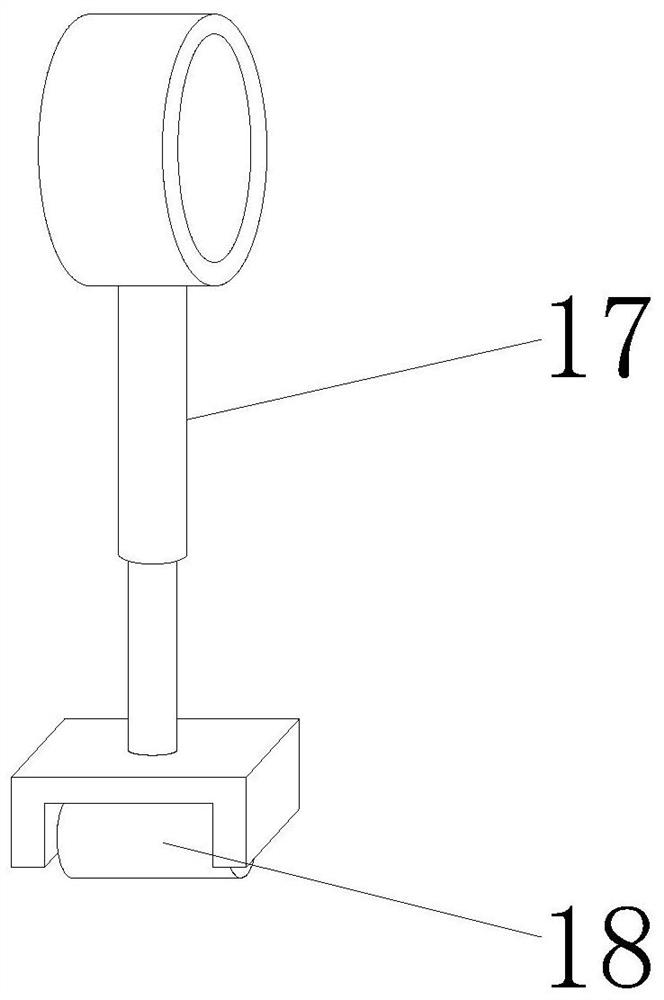

[0019] according to figure 1 , 2 , 3, and 4, this embodiment proposes a pull-out test device for processing nylon heat-insulating strips, including a base 1 and a clamping assembly, and both ends of the top side of the base 1 are provided with a first chute 2. A slide plate 3 is movably installed on the first chute 2, a U-shaped frame 4 is provided on the slide plate 3, and a first air cylinder 5 is provided at the middle position of the top of the U-shaped frame 4, and the first air pressure The output end of the cylinder 5 runs through the U-shaped frame 4 and is provided with a clamping plate 6, the middle position of the top of the base 1 is provided with a second chute 7, and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com