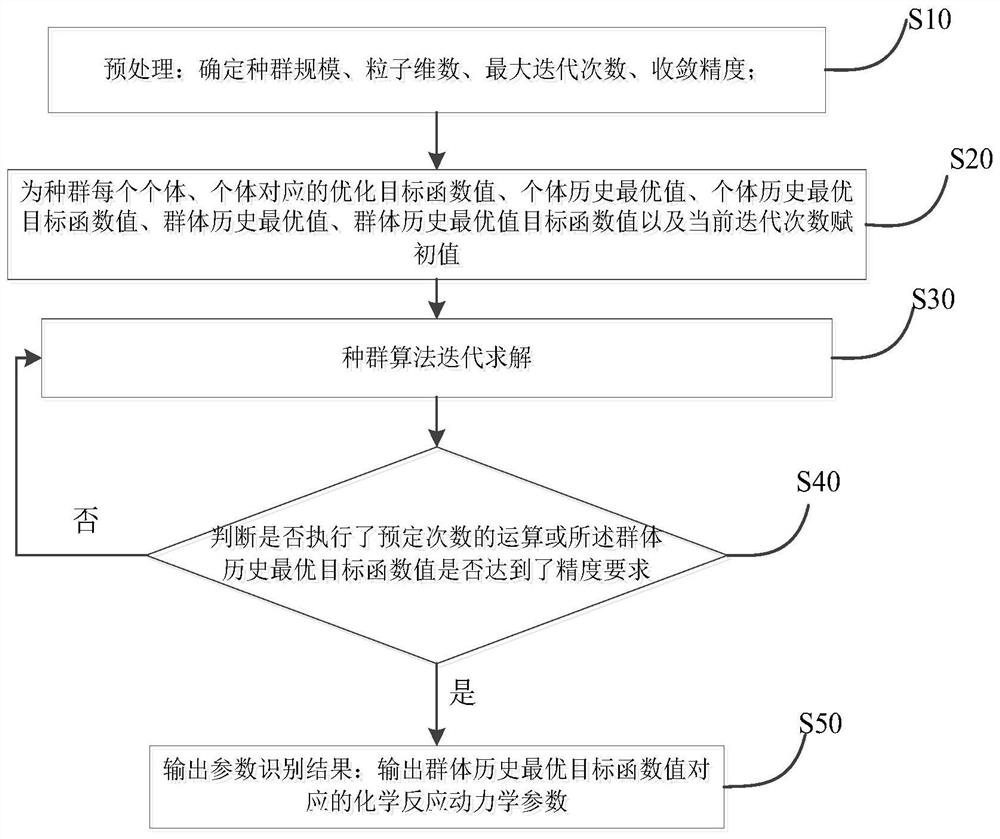

High polymer slurry parameter recognition method based on swarm intelligence optimization algorithm

An intelligent optimization algorithm and optimization algorithm technology, applied in the field of chemical grouting, can solve the problems of inaccuracy and slow identification of chemical reaction kinetic parameters, etc., and achieve the effect of fast and accurate identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

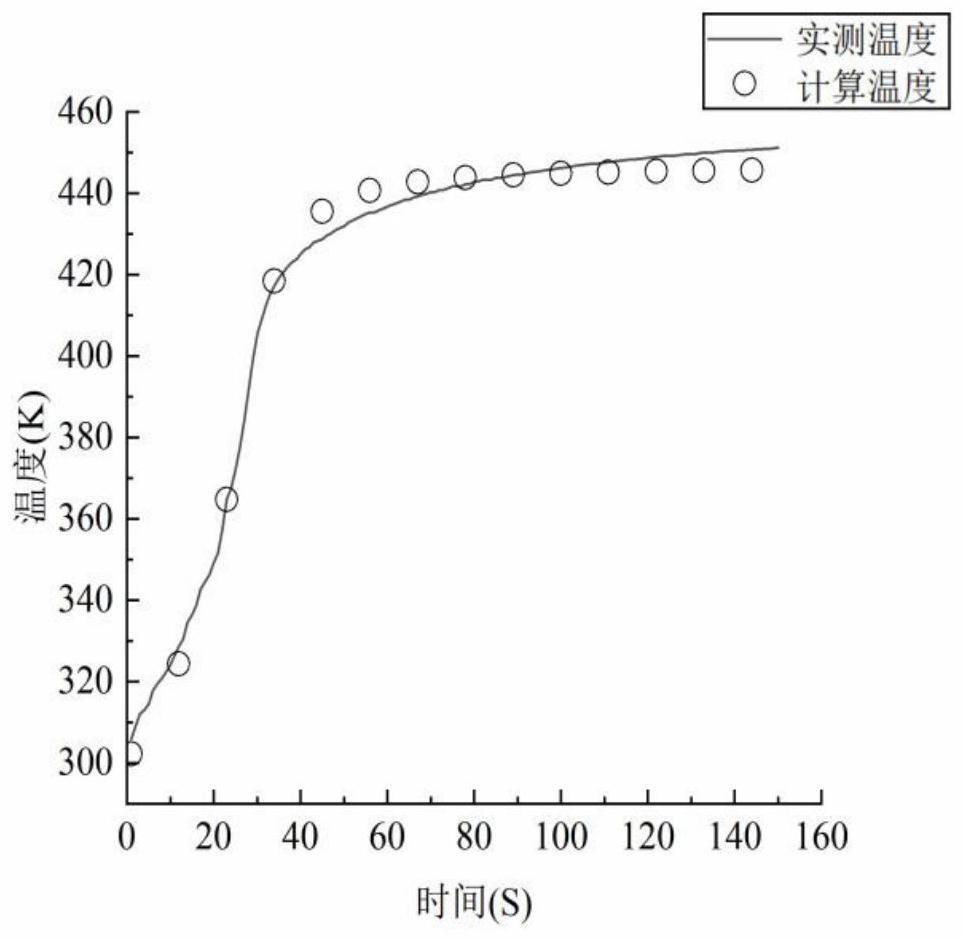

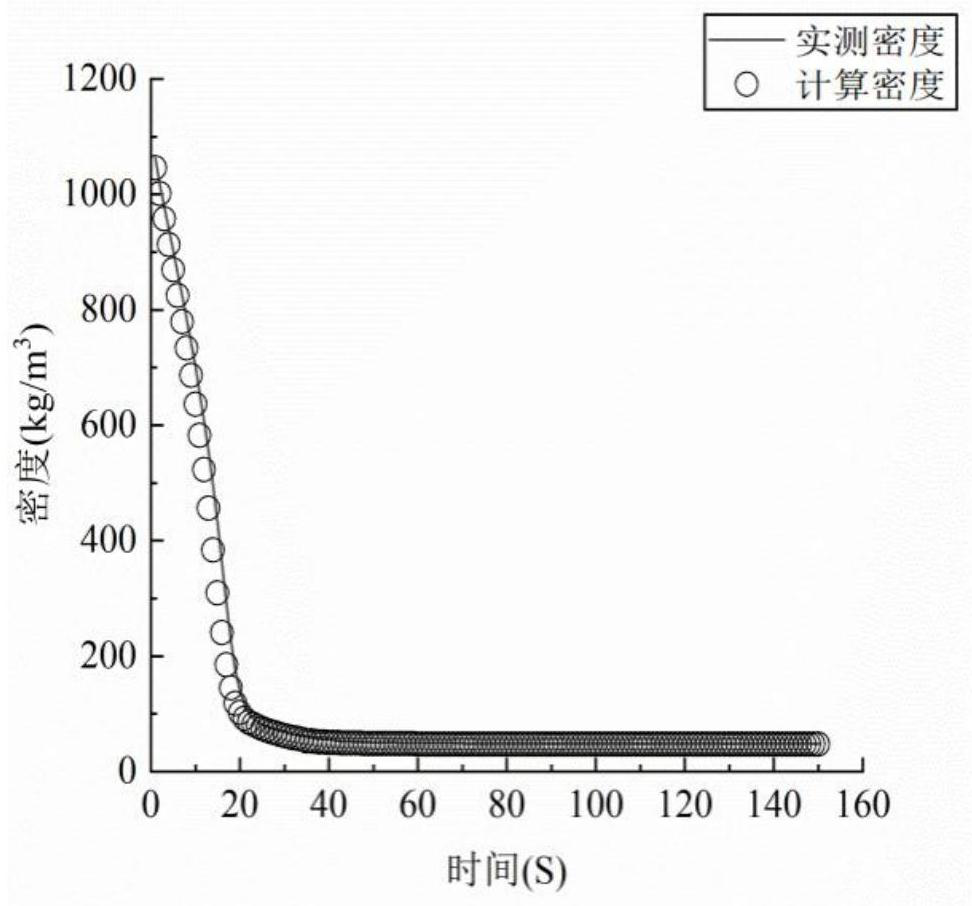

[0050] In this embodiment, the self-expanding polymer slurry chemical reaction kinetics parameter identification method based on the swarm intelligence optimization algorithm is adopted, combined with the temperature and density test data during the chemical reaction process of the self-expanding polymer slurry, the slurry chemical reaction kinetics parameter identification. First set the component parameters and related physical parameters of the self-expanding polymer slurry: the component concentration of the slurry c OH,0 4079.6mol / m 3 , c NCO,0 4557.7mol / m 3 , c W,0 294.7mol / m 3 , density ρ p 1100kg / m 3 , ρ W 1000kg / m 3 , heat of reaction (-△H) W 8.6×10 4 J·mol -1 , (-△H) OH is 7.075×10 4 J·mol -1 , r BL,0 1228kg / m 3 , 4.4×10 4 , C p is 1800J / (kg·K), is 836.6J / (kg·K), C BL is 1159J / (kg·K), C BG is 1000J / (kg·K), and λ is 206.8kJ / kg.

[0051] The swarm intelligence optimization algorithm in this embodiment specifically adopts the particle swarm opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com