Wafer bonding and packaging method of silicon-based OLED

A packaging method and silicon-based technology, which is applied in the manufacturing of electrical components, electrical solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of easy clogging of the glue application needle, unsmooth glue dispensing, and long glue application time, so as to avoid defects. Side effects, improving production efficiency, and speeding up the effect of gluing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be explained more clearly and completely through the description of preferred embodiments of the present invention in conjunction with the accompanying drawings.

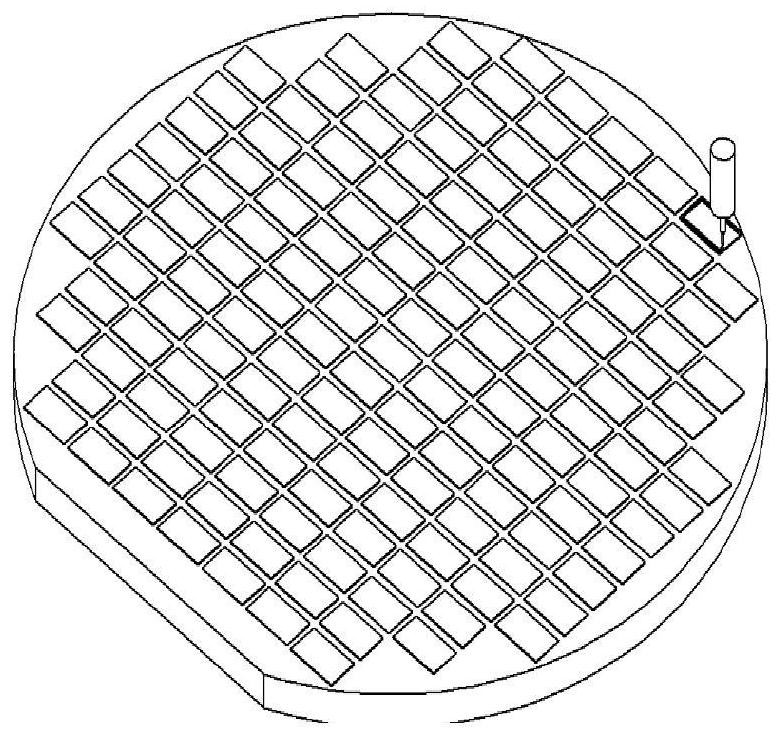

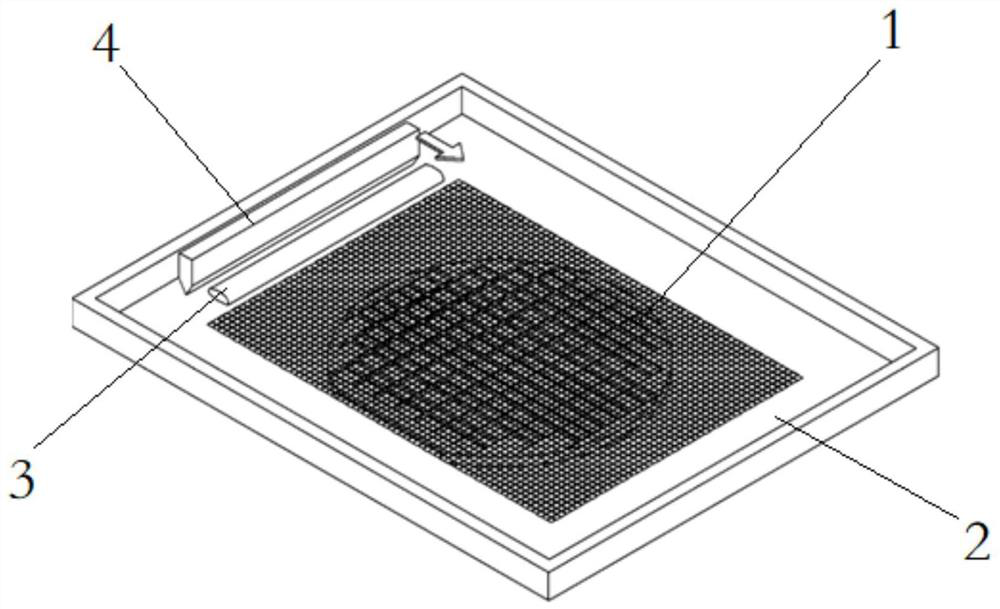

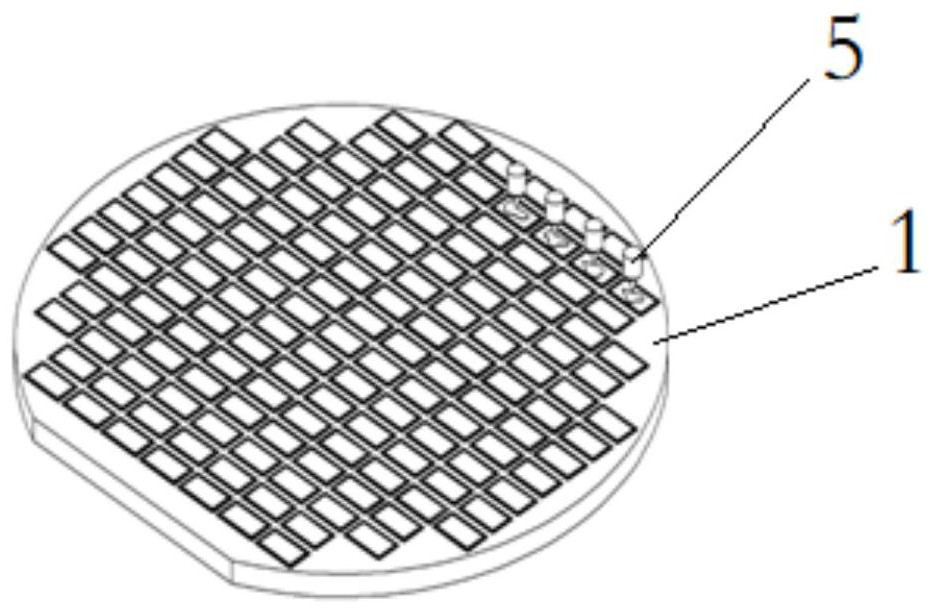

[0025] like Figure 2 to Figure 4 As shown, the silicon-based OLED wafer bonding and packaging method of the preferred embodiment of the present invention includes the following steps:

[0026] Step 1: Apply the structural adhesive to the silicon-based substrate by screen printing technology.

[0027] Specifically, the first step is: place the screen 2 on the silicon substrate 1, place the structural glue 3 on one side of the screen 2, and apply the structural glue 3 on the outside of the structural glue 3 along one direction with the scraper 4. On the mesh plate 2 and the silicon base substrate 1. Preferably, the porosity of the mesh plate is 2%-59%.

[0028] Preferably, after the structural adhesive is coated, UV curing structural adhesive is used.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com