Auxiliary screening device for electronic element quality detection

A technology for quality testing and electronic components, which is applied in the field of auxiliary screening devices for quality testing of electronic components, can solve problems such as damage, high impact force, and fast delivery of electronic components, and prevent the delivery speed from being too fast and the moving speed from being too fast fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

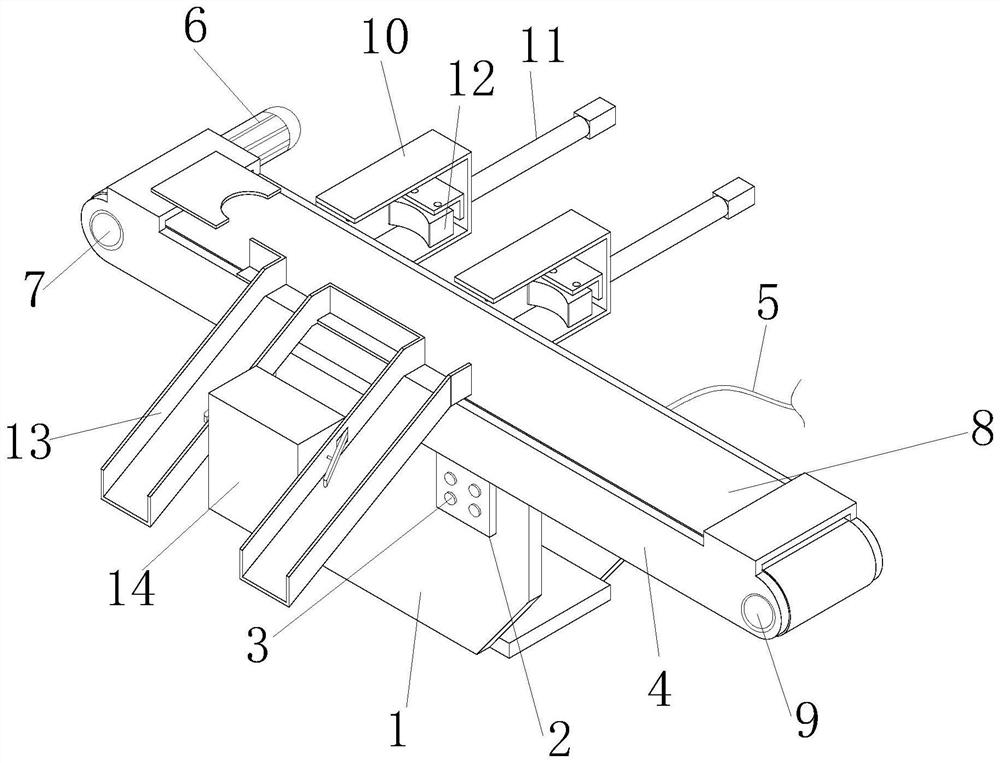

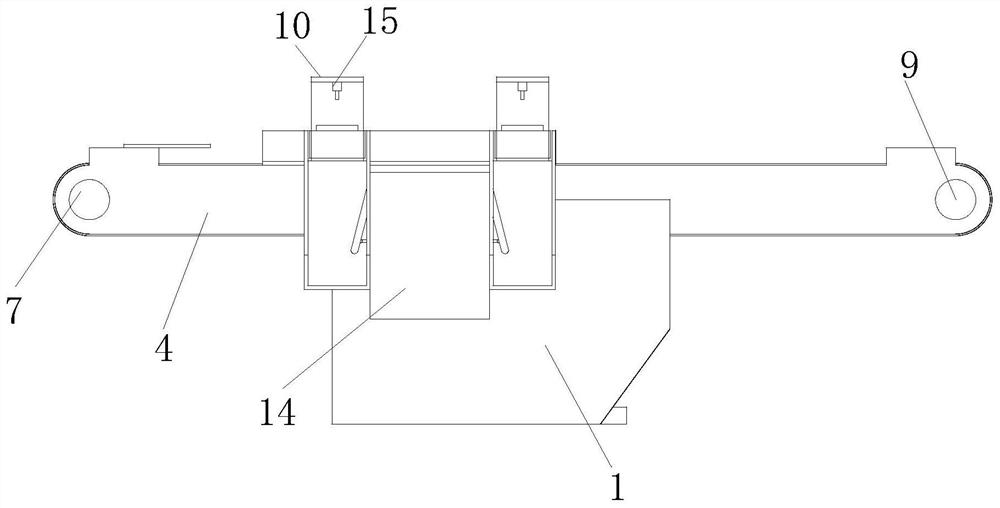

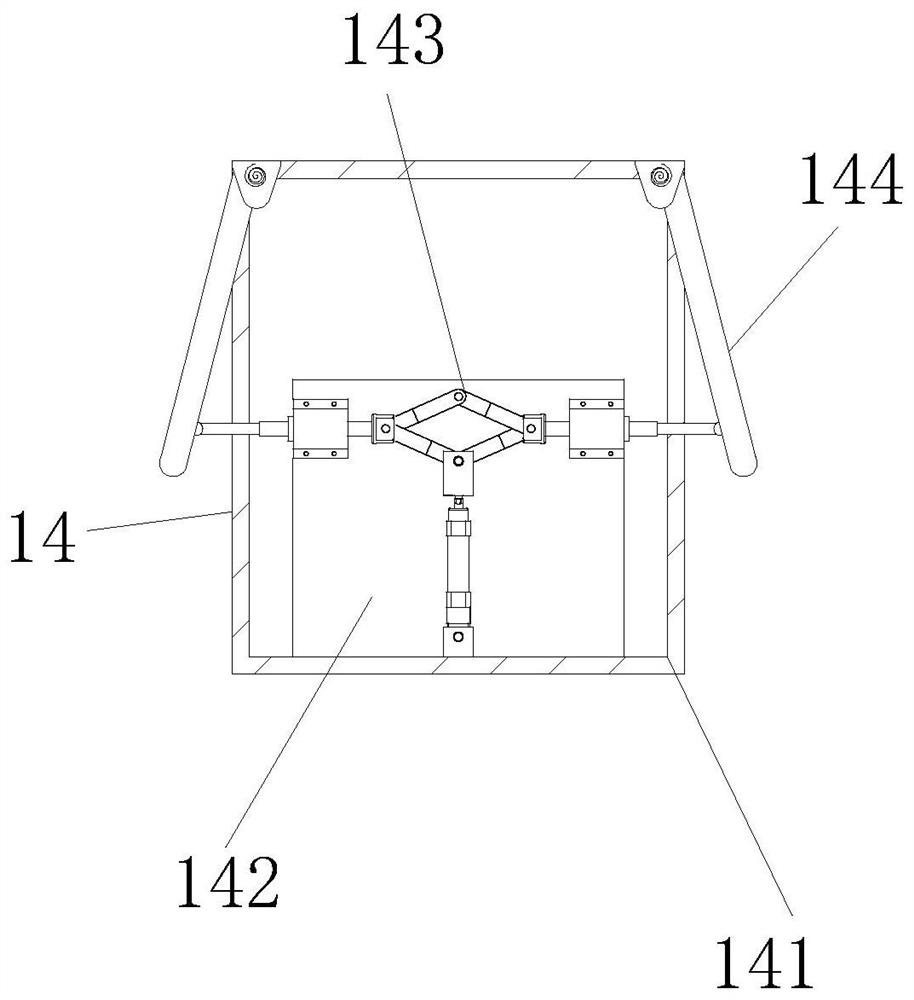

[0029] see figure 1 with figure 2 , the present invention provides an auxiliary screening device for quality detection of electronic components through improvement, including a support base 1, a motor 6, a first roller 7, a conveyor belt 8, a push block 12, a detection probe 15 and a flow blocking buffer mechanism 14 , the front end of the support seat 1 is provided with a control panel 2, the front end of the control panel 2 is equipped with a button 3, the support seat 1 is fixedly connected with the bottom of the support frame 4, the rear end of the support seat 1 is fixed with a power wire 5, the flow resistance buffer mechanism 14 is connected with the discharge pipe 13 The middle part is fixedly connected, the support seat 1 is locked and fixed with the front end of the motor 6 through screws, the output end of the motor 6 is connected to the first rotating roller 7 in rotation, the first rotating roller 7 is connected to the second rotating roller 9 through a conveyor ...

Embodiment 2

[0034] The present invention provides an auxiliary screening device for quality detection of electronic components through improvement. The first rotating roller 7 and the second rotating roller 9 have the same size, and the first rotating roller 7 and the second rotating roller 9 are distributed horizontally. It is beneficial to play the role of smooth transmission of the conveyor belt 8. There are two fixed mounts 10, the first cylinder 11 and the push block 12, which are respectively located on the left and right sides of the rear end of the discharge pipe 13, which is beneficial to screen the electronic components. Function, the upper end of the inclined plate 1443 is provided with a rubber pad 14431, which is beneficial to Tiida to protect the electronic components.

[0035] The present invention provides an auxiliary screening device for quality detection of electronic components through improvement, and its working principle is as follows;

[0036] First, before use, pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com