Quartz continuous melting furnace capable of reducing pipe wall deflection

A continuous melting furnace and partial wall technology, which is applied in the field of quartz continuous melting furnace production equipment, can solve problems such as core rod shaking and instability, and achieve the effects of ensuring stability, avoiding partial wall, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

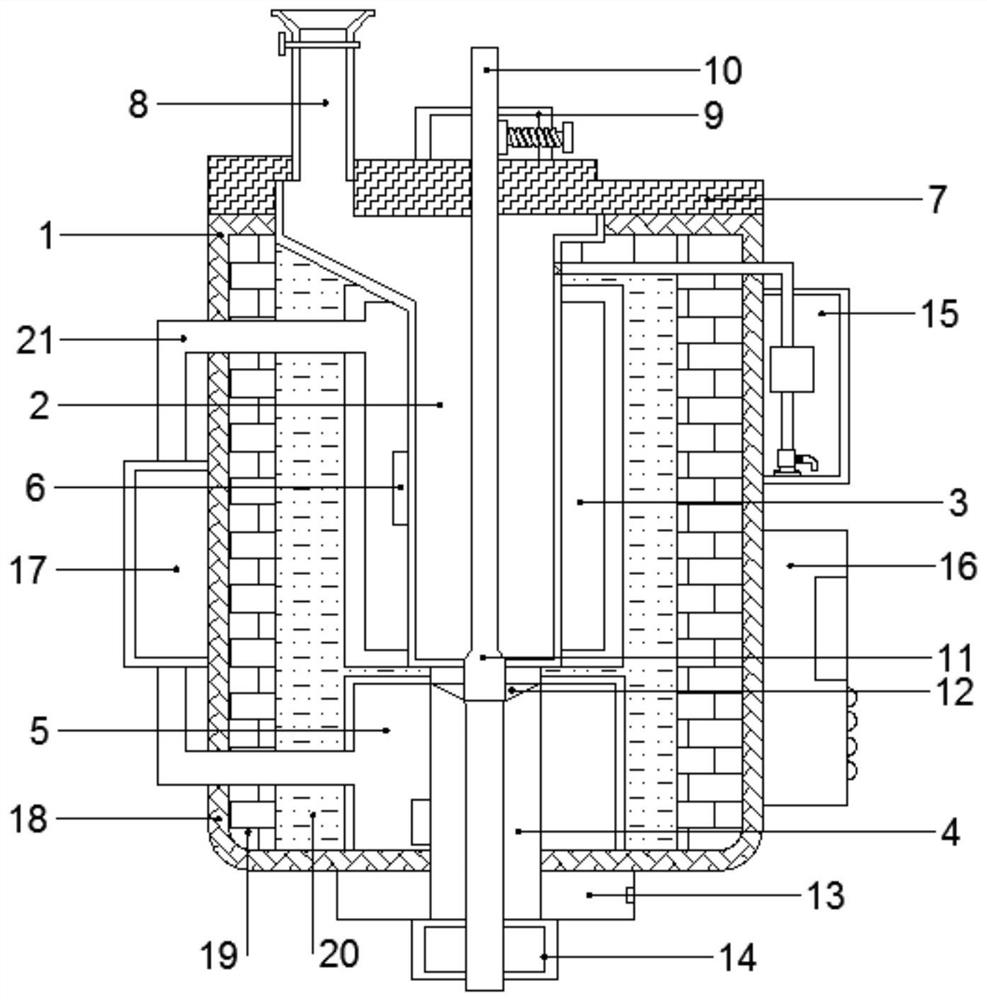

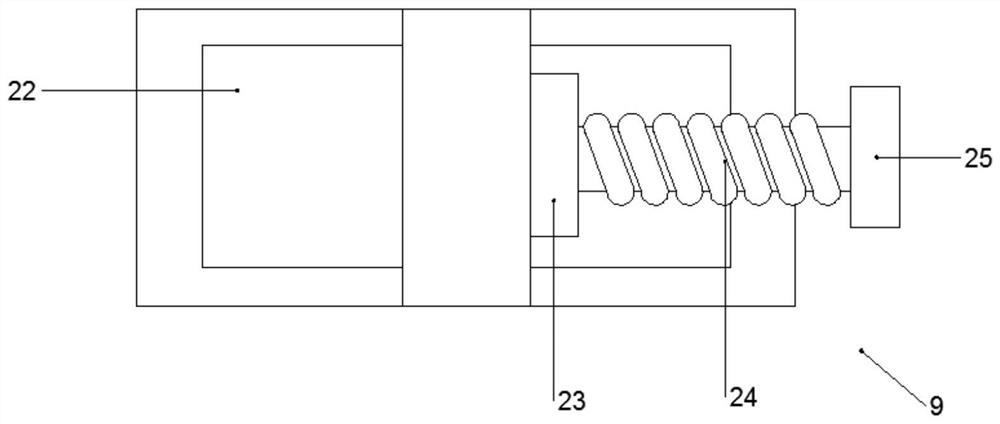

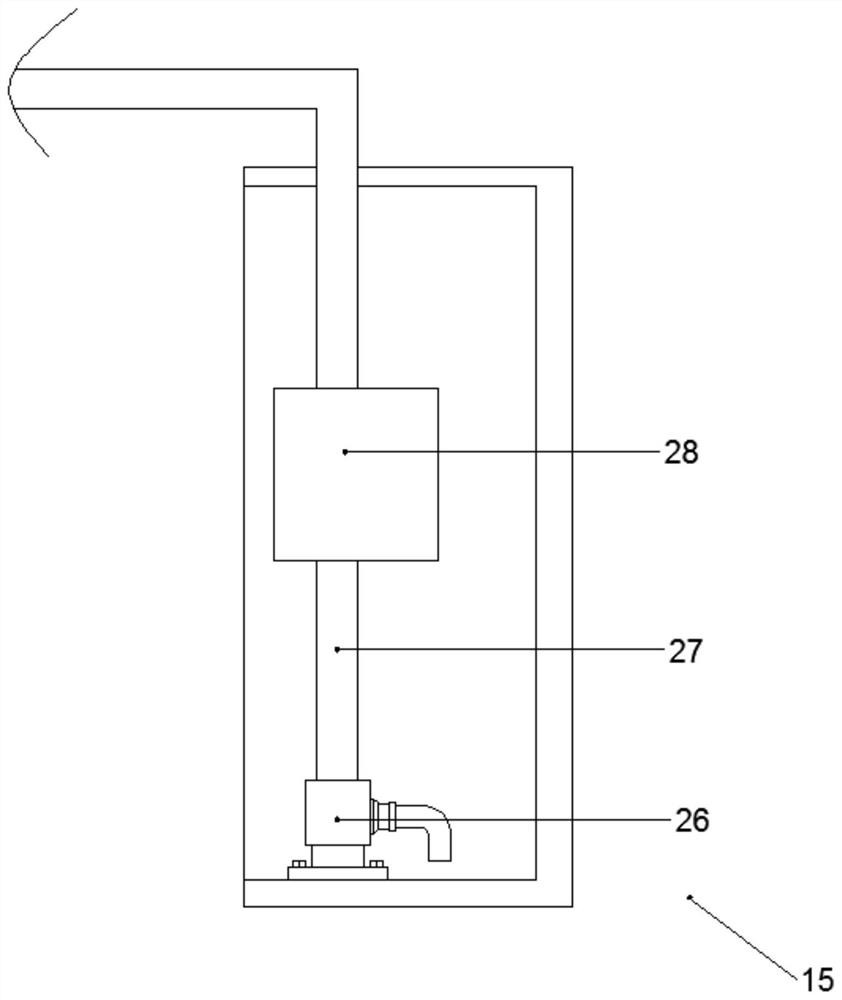

[0020] Example: such as Figure 1-3 As shown, the present invention is a quartz continuous melting furnace that can reduce the partial wall of the pipe, including a furnace body 1, a crucible 2 is fixedly installed inside the furnace body 1, a first heating chamber 3 is fixedly installed outside the crucible 2, and the A discharge chamber 4 is fixedly installed at the bottom of the crucible 2, a second heating chamber 5 is fixedly installed outside the discharge chamber 4, and a temperature sensor 6 is fixedly installed inside the first heating chamber 3 and the second heating chamber 5, A furnace cover 7 is fixedly installed on the top of the furnace body 1, a feed pipe 8 is fixedly installed on the top of the furnace cover 7, and a clamping seat 9 is fixedly installed on one side of the feed pipe 8, and the inside of the clamping seat 9 is A core rod 10 is fixedly installed, and the core rod 10 extends through the furnace cover 7 to the inside of the crucible 2, and a former...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com