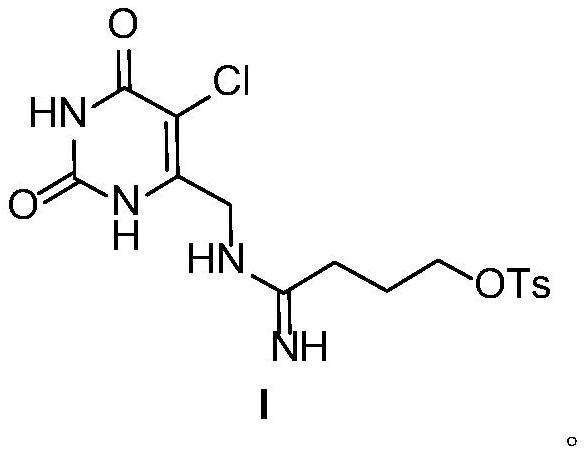

Tipiracil intermediate compound

A technology for tipiracil and intermediates, applied in the field of drug synthesis, can solve the problems of difficult to pass the target product and low yield, and achieve the effect of being suitable for industrial production, easy to operate, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

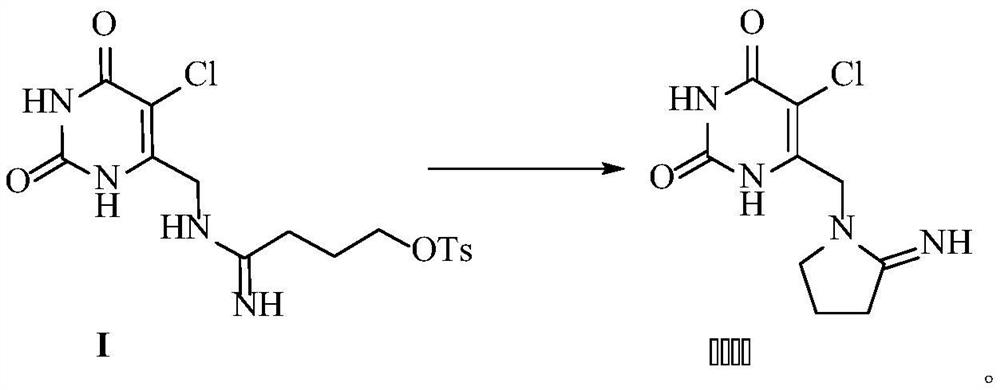

Method used

Image

Examples

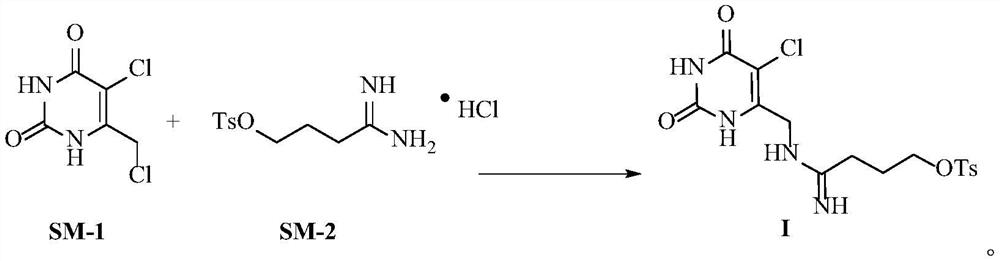

Embodiment 1

[0065] Add SM-1 (9.75g, 50mmol) and SM-2 (18.30g, 62.5mmol) into methanol (80mL), until the materials are completely dissolved, add dropwise a solution of DBU (24.36g, 160mmol) dissolved in methanol (30mL) , the dropwise addition is completed, the temperature is controlled at 45-50°C for 14 hours, the reaction solution is filtered while it is hot, the filtrate is cooled to 0-5°C, stirred and crystallized for 2-3 hours, filtered with suction, and the obtained filter cake is vacuum-dried to obtain the pyrazidine intermediate Compound I, yield 93.5%, purity 99.88%.

Embodiment 2

[0067] Add SM-1 (9.75g, 50mmol) and SM-2 (16.10g, 55.0mmol) into methanol (80mL), until the materials are completely dissolved, add dropwise a solution of DBU (30.45g, 200mmol) dissolved in methanol (30mL) , the dropwise addition is completed, the temperature is controlled at 45-50°C for 14 hours, the reaction solution is filtered while it is hot, the filtrate is cooled to 0-5°C, stirred and crystallized for 2-3 hours, filtered with suction, and the obtained filter cake is vacuum-dried to obtain the pyrazidine intermediate Compound I, yield 90.8%, purity 99.75%.

Embodiment 3

[0069] Add SM-1 (9.75g, 50mmol) and SM-2 (20.50g, 70mmol) in methanol (80mL), until the materials are completely dissolved, add dropwise a solution of DBU (19.03g, 125mmol) dissolved in methanol (30mL), After the dropwise addition is completed, the temperature is controlled at 45-50°C for 14 hours, the reaction solution is filtered while it is hot, the filtrate is cooled to 0-5°C, stirred and crystallized for 2-3 hours, filtered with suction, and the obtained filter cake is vacuum-dried to obtain pyrazidine intermediate I The compound has a yield of 90.5% and a purity of 99.73%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com