Method for preparing high-yield and high-aryl ether bond structure lignin from wood fiber biomass

A technology for wood fiber and biomass, which is applied in the field of preparing high yield and high aryl ether bond structure lignin, can solve the problems of low aryl ether bond content and high carbon-carbon bond content, and achieves low cost and high carbon-carbon bond content. High, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

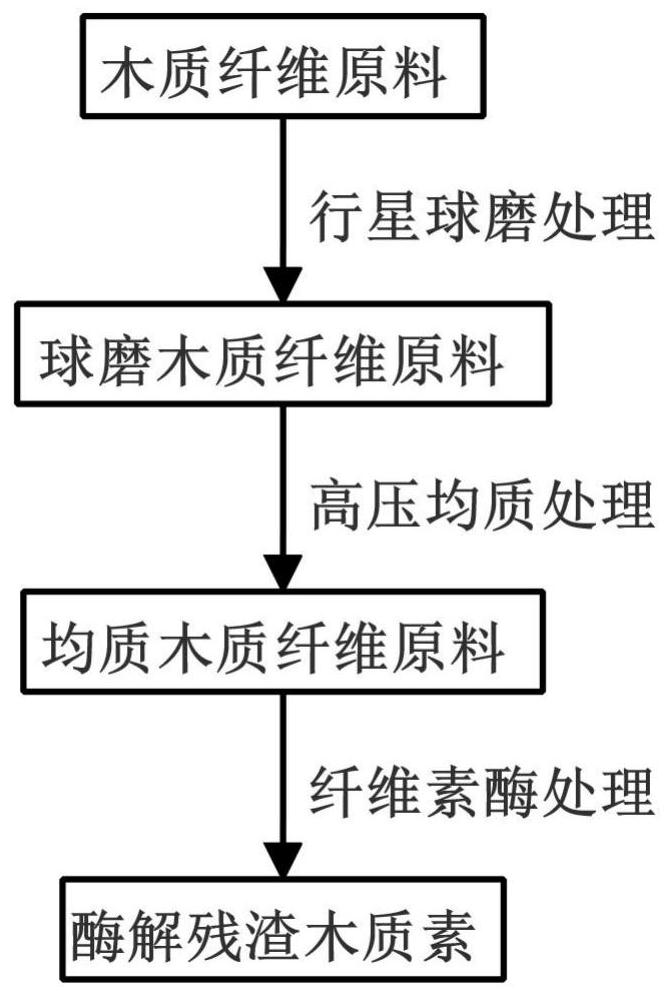

[0036] A method for preparing lignin with high yield and high aryl ether bond structure from lignocellulosic biomass, comprising the steps of:

[0037] 1) Pretreatment: remove impurities from the balsa raw material, crush it to a fineness of 20-60 mesh, and dry it to obtain the lignocellulosic biomass raw material for subsequent use;

[0038] 2) Ball milling: the lignocellulose raw material obtained in step 1) was ball milled at 450 rpm for 2 hours, and set aside;

[0039] 3) Homogenization: Homogenize the pulverized raw materials obtained in step 2) in a homogenizer, control the operating pressure to 150MPa, the homogeneous injection concentration is 2.5%, and the homogenization times are 10 times, and the obtained samples are used for future use ;

[0040]4) Enzymolysis: Add the raw material obtained in step 3) to sodium acetate buffer solution with a pH of 4.8, then add 35 FPU cellulase / gram substrate, and perform enzymolysis at 50° C. for 48 hours.

[0041] 5) Separation...

Embodiment 2

[0044] A method for preparing lignin with high yield and high aryl ether bond structure from lignocellulosic biomass, comprising the steps of:

[0045] 1) Pretreatment: removing impurities from the parenchyma cell raw material of moso bamboo, crushing to a fineness of 20-60 mesh, and drying to obtain the lignocellulosic biomass raw material, which is set aside;

[0046] 2) Ball milling: the lignocellulose raw material obtained in step 1) was ball milled at 400 rpm for 2.5 hours, and set aside;

[0047] 3) Homogenization: the pulverized raw material obtained in step 2) is homogenized in a homogenizer, the control operating pressure is 130MPa, the homogeneous injection concentration is 1.5%, the number of homogenization times is 8 times, and the obtained sample is used for future use ;

[0048] 4) Enzymolysis: Add the raw material obtained in step 3) to sodium acetate buffer solution with a pH of 5.0, then add 30 FPU cellulase / gram substrate, and perform enzymolysis at 45-55° C...

Embodiment 3

[0052] A method for preparing lignin with high yield and high aryl ether bond structure from lignocellulosic biomass, comprising the steps of:

[0053] 1) Pretreatment: removing impurities from the Manila hemp raw material, crushing to a fineness of 100-150 mesh, and drying to obtain the lignocellulosic biomass raw material for subsequent use;

[0054] 2) Ball milling: the lignocellulose raw material obtained in step 1) was ball milled at 500 rpm for 3.5 hours, and set aside;

[0055] 3) Homogenization: Homogenize the pulverized raw materials obtained in step 2) in a homogenizer, control the operating pressure to 140 MPa, the homogeneous injection concentration is 1%, and the homogenization times are 10 times, and the obtained samples are used for later use;

[0056] 4) Enzymolysis: Add the raw material obtained in step 3) to sodium acetate buffer solution with a pH of 5.5, then add 50 FPU cellulase / gram substrate, and perform enzymolysis at 45° C. for 72 hours.

[0057] 5) S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com