A kind of impregnation resin and preparation method thereof

A technology of impregnating resin and polyester resin, used in coatings, polyester coatings, etc., can solve the problems of insolubility, unfavorable structure control, failure, etc., to achieve high adhesion, excellent electrical properties and flexibility, curing low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

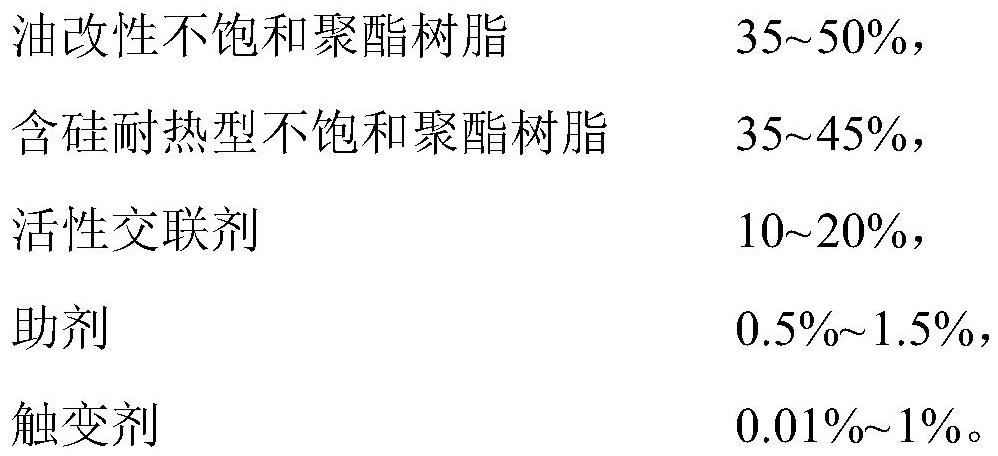

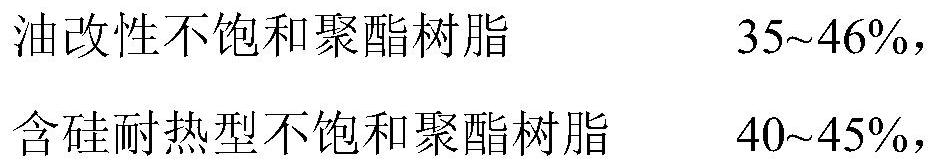

Method used

Image

Examples

Embodiment 1

[0059]After mixing 150g of soybean oil, 11g of monoethanolamine, 15g of glycerin, and 0.2g of sodium methoxide, they were incubated at 180°C for 4 hours, and the reaction was stopped until the amine value was less than or equal to 2mgKOH / g to obtain an intermediate.

[0060] After mixing 500g of neopentyl glycol, 270g of maleic anhydride, 270g of phthalic anhydride, and 176g of intermediates, add 0.5g of hydroquinone, and keep the temperature at 210°C for 3 hours, and control the atmospheric temperature to ≤105°C until the acid value ≤28mgKOH / g, the reaction is stopped to obtain an oil-modified unsaturated polyester.

[0061] 40g oil-modified unsaturated polyester resin, 45g silicon-containing heat-resistant unsaturated polyester resin (JR01 resin produced by Nantong Tianhe Company), 20g styrene, 0.1g cobalt naphthenate, 0.8g diisoperoxide Propylbenzene, 0.06g of p-tert-butylcatechol, and 0.5g of hydrogenated castor oil are mixed evenly, then dispersed evenly under the action ...

Embodiment 2

[0063] (1) After mixing 130g of soybean oil, 9.5g of monoethanolamine, 20g of glycerin, and 0.2g of sodium methoxide, the mixture was incubated at 175°C for 3 hours, and the reaction was stopped until the amine value was less than or equal to 2mgKOH / g to obtain an intermediate.

[0064] (2) After mixing 525g of neopentyl glycol, 275g of maleic anhydride, 275g of phthalic anhydride, and 139.5g of intermediates, add 0.5g of hydroquinone, and keep the temperature at 205°C for 3.5 hours, and control the weather temperature to ≤105°C , stop the reaction until the acid value ≤ 28mgKOH / g, and obtain the oil-modified unsaturated polyester.

[0065] (3) 40g oil-modified unsaturated polyester resin, 40g silicon-containing heat-resistant unsaturated polyester resin (JR01 resin produced by Nantong Tianhe Company), 15g styrene, 0.1g cobalt naphthenate, 0.8g supernatant Mix dicumyl oxide, 0.06g p-tert-butylcatechol, and 0.5g white carbon black evenly, then disperse evenly under high shear a...

Embodiment 3

[0067] After mixing 120g of soybean oil, 8.7g of monoethanolamine, 25g of glycerin, and 0.2g of sodium methoxide, the mixture was incubated at 170°C for 2.5 hours, and the reaction was stopped until the amine value was less than or equal to 2mgKOH / g to obtain an intermediate.

[0068] After mixing 550g of neopentyl glycol, 278g of maleic anhydride, 276g of phthalic anhydride, and 128.7g of intermediates, add 0.5g of hydroquinone, and keep the temperature at 200°C for 4 hours. When the value is less than or equal to 28mgKOH / g, the reaction is stopped to obtain an oil-modified unsaturated polyester.

[0069] 45g oil-modified unsaturated polyester resin, 40g silicon-containing heat-resistant unsaturated polyester resin (JR01 resin produced by Nantong Tianhe Company), 12g styrene, 0.1g cobalt naphthenate, 0.8g diisoperoxide Propylbenzene, 0.06g of p-tert-butylcatechol, and 0.5g of hydrogenated castor oil are mixed evenly, then dispersed evenly under the action of high shear at a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com