Environmentally-friendly high-paint-hanging-amount pure resin impregnated insulating paint and preparation method thereof

A technology of resin impregnation and insulating varnish, applied in the direction of polyester coating, coating, etc., can solve the problems of environmental impact, less paint hanging on motors, waste of insulating paint, etc., to improve quality, increase paint hanging, and reduce pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

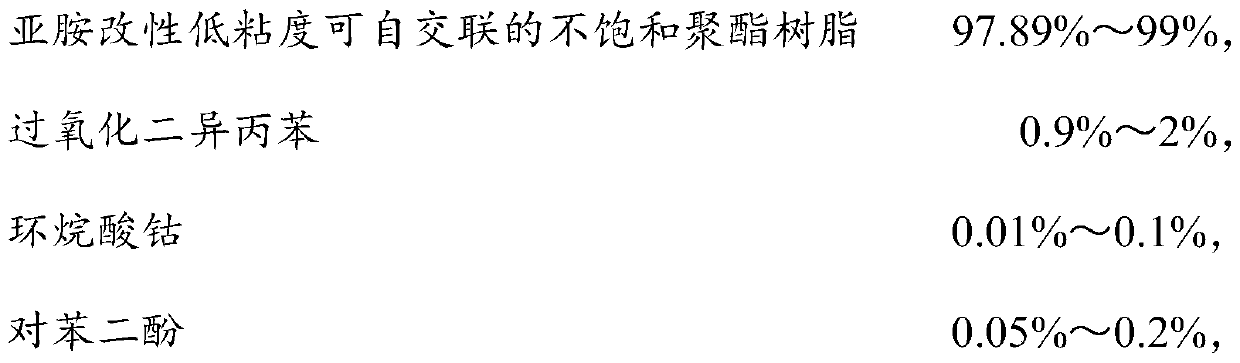

[0036] This embodiment 1 provides an environment-friendly high-hanging paint volume pure resin impregnated insulating varnish, including the following components by weight percentage:

[0037]

[0038]

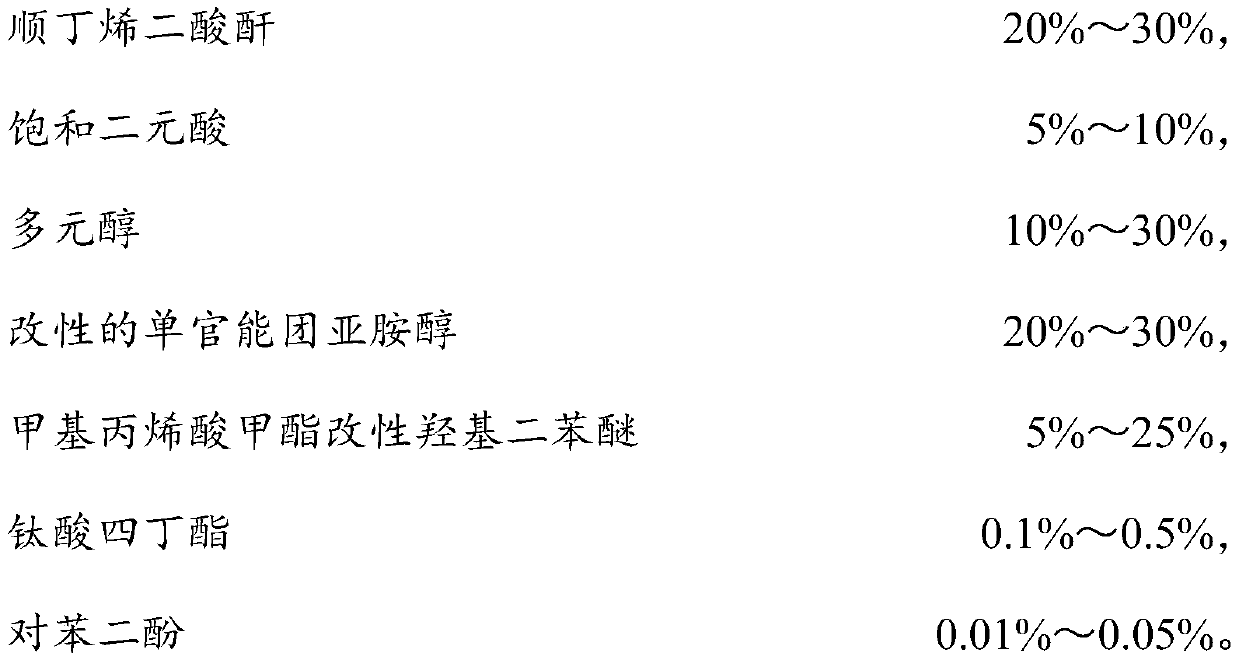

[0039] Wherein, by weight percentage, imine-modified low-viscosity self-crosslinkable unsaturated polyester resin is made from the following raw materials:

[0040]

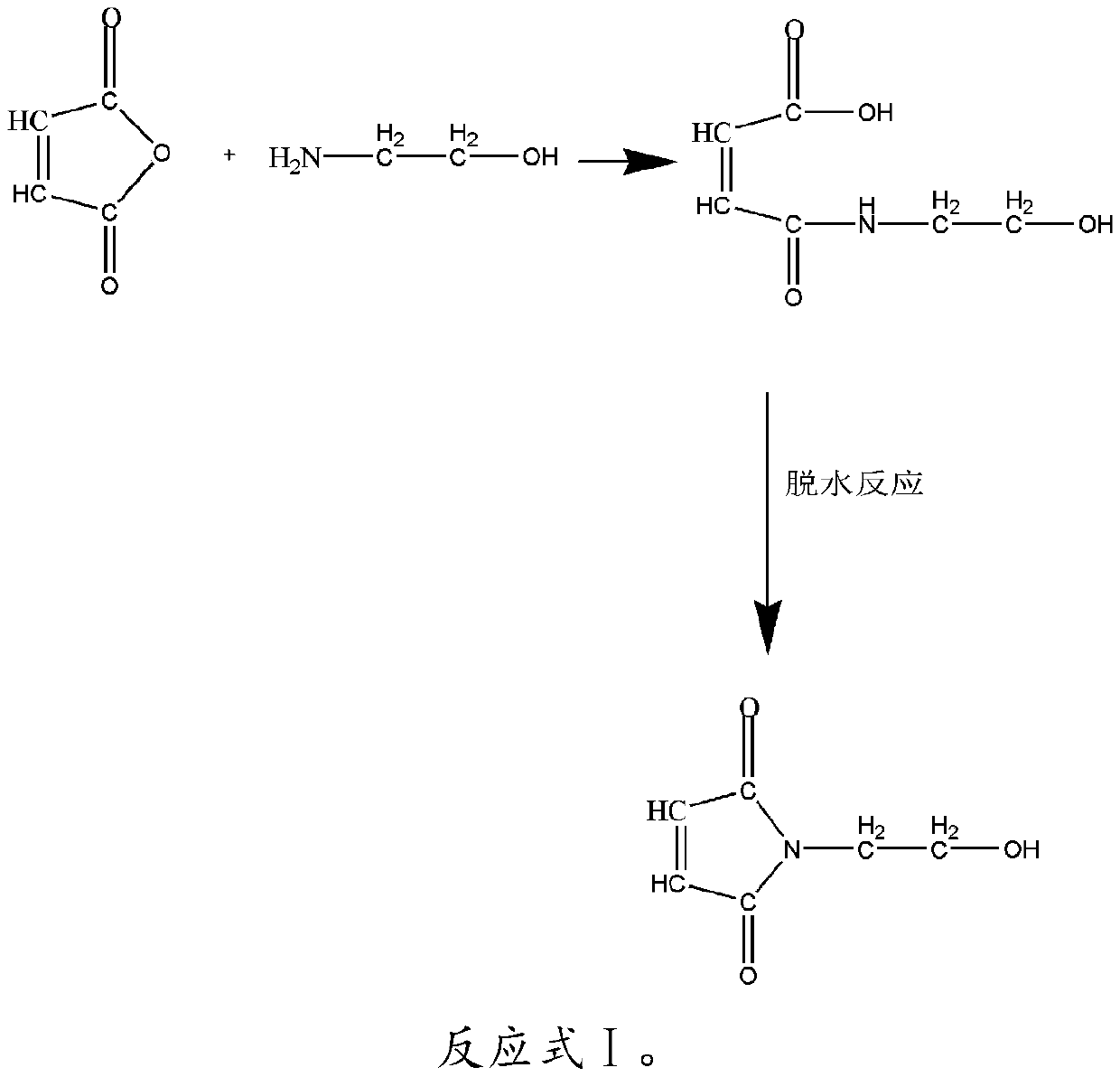

[0041] In terms of weight percentage, the modified monofunctional imino alcohol is synthesized from 61.4% maleic anhydride, 31.3% ethanolamine and 0.3% catalyst butoxytin.

[0042]In percent by weight, methyl methacrylate modified hydroxydiphenyl ether consists of 33% methyl methacrylate, 66.7% 4,4'-dihydroxydiphenyl ether, 0.15% catalyst tetrabutyl titanate and 0.15% polymerization inhibitor hydroquinone is synthesized.

[0043] The preparation method of the above-mentioned environmentally friendly high-hanging paint volume pure resin-impregnated insulating varnish comprises the following steps:

[00...

Embodiment 2

[0049] This embodiment 2 provides an environment-friendly high paint hanging volume pure resin impregnated insulating varnish, including the following components by weight percentage:

[0050]

[0051] Wherein, by weight percentage, imine-modified low-viscosity self-crosslinkable unsaturated polyester resin is made from the following raw materials:

[0052]

[0053] In terms of weight percentage, the modified monofunctional imino alcohol is synthesized from 61.4% maleic anhydride, 31.3% ethanolamine and 0.3% catalyst butoxytin.

[0054] In percent by weight, methyl methacrylate modified hydroxydiphenyl ether consists of 33% methyl methacrylate, 66.7% 4,4'-dihydroxydiphenyl ether, 0.15% catalyst tetrabutyl titanate and 0.15% polymerization inhibitor hydroquinone is synthesized.

[0055] The preparation method of the above-mentioned environmentally friendly high-hanging paint volume pure resin-impregnated insulating varnish comprises the following steps:

[0056] (1) Syn...

Embodiment 3

[0061] This embodiment 3 provides an environment-friendly high-hanging paint volume pure resin impregnated insulating varnish, including the following components by weight percentage:

[0062]

[0063] Wherein, by weight percentage, imine-modified low-viscosity self-crosslinkable unsaturated polyester resin is made from the following raw materials:

[0064]

[0065]

[0066] In terms of weight percentage, the modified monofunctional imino alcohol is synthesized from 61.4% maleic anhydride, 31.3% ethanolamine and 0.3% catalyst butoxytin.

[0067] In percent by weight, methyl methacrylate modified hydroxydiphenyl ether consists of 33% methyl methacrylate, 66.7% 4,4'-dihydroxydiphenyl ether, 0.15% catalyst tetrabutyl titanate and 0.15% polymerization inhibitor hydroquinone is synthesized.

[0068] The preparation method of the above-mentioned environmentally friendly high-hanging paint volume pure resin-impregnated insulating varnish comprises the following steps:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com