A kind of impregnation resin for electric vehicle motor and preparation method thereof

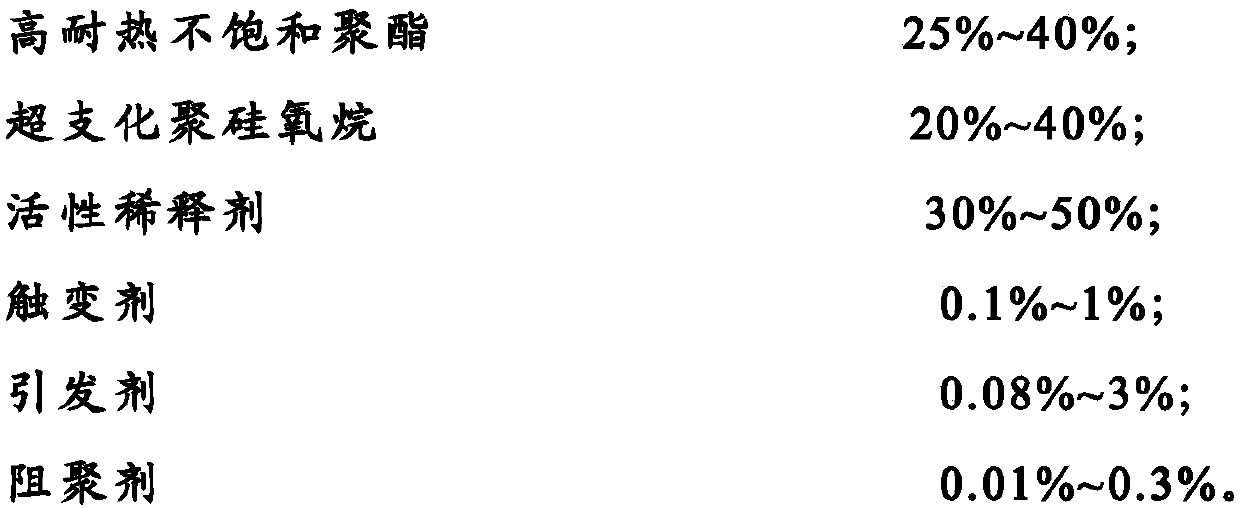

A technology of impregnating resin and formula, which is applied in the field of impregnating resin with high heat resistance, water resistance, oil resistance, high paint hanging capacity, insulation impregnation of motor and electrical winding coil, and can solve the complex and comprehensive process of ultraviolet radiation heat curing It is difficult to promote and apply, and it affects the performance of impregnated resins, etc., to achieve the effects of avoiding easy precipitation, low resin loss, and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

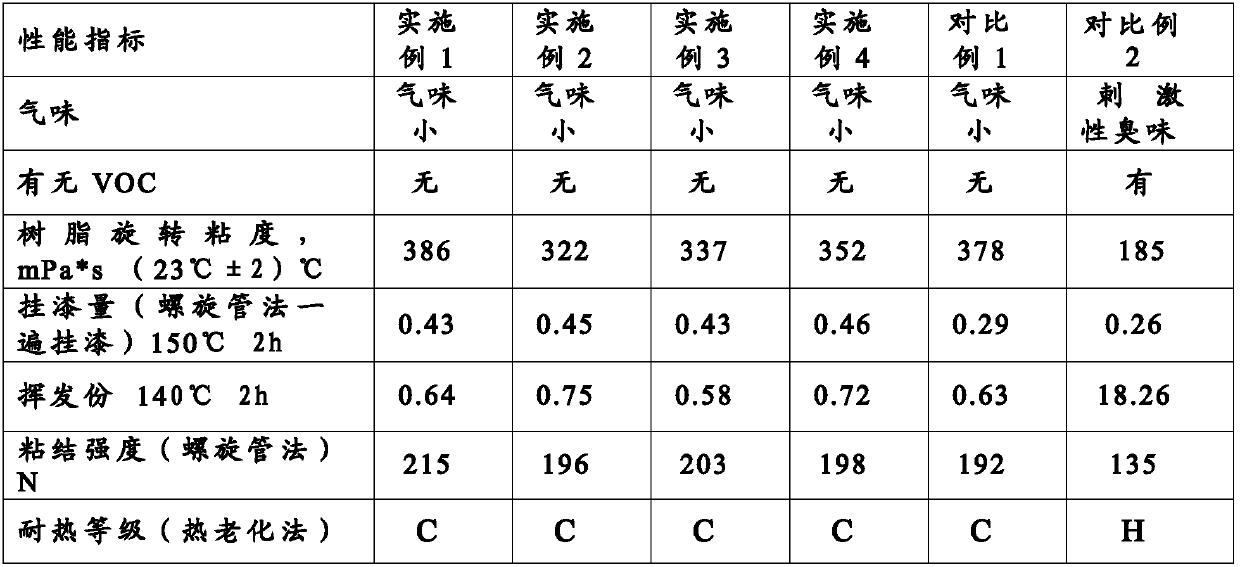

Examples

Embodiment 1

[0029] (1) Weigh 500g of vinyltrimethoxysilane and 20g of deionized water into a three-necked reaction flask, adjust the pH value of the system to 1 with HCl, raise the temperature at 60°C, and react for 3 hours. Add 216g of benzyl alcohol, 0.5g of hydroquinone, 0.22g of stannous chloride, slowly raise the temperature to 140°C, keep the temperature for 3 hours, vacuumize to remove the remaining methanol, end the reaction, cool to room temperature, and prepare hyperbranched polysiloxane alkyl.

[0030] (2) Add 300g of vinyltrimethoxysilane, 878g of hydroxypropyl methacrylate, 1g of hydroquinone, and 0.58g of stannous chloride into a three-necked reaction flask, heat up to 145°C, keep warm for 4 hours, and then vacuumize Remove excess methanol and cool to obtain an active diluent.

[0031] (3) Weigh 200g of high heat-resistant unsaturated polyester, 180g of hyperbranched polysiloxane, 330g of reactive diluent, 2.1g of BYK-431, 7g of dicumyl peroxide, and 0.35g of catechol at 45...

Embodiment 2

[0033] (1) Weigh 850g of vinyltrimethoxysilane and 41.3g of deionized water into a three-necked reaction flask, adjust the pH value of the system to 1.5 with HCl, raise the temperature at 58°C, and react for 3 hours. Add 195g of benzyl alcohol, 0.93g of hydroquinone, and 0.45g of stannous chloride, slowly raise the temperature to 140°C, keep the temperature for 3 hours, vacuumize to remove the remaining methanol, end the reaction, and cool to room temperature to obtain hyperbranched polysiloxane alkyl.

[0034] (2) Add 320g of vinyltrimethoxysilane, 860g of hydroxyethyl methacrylate, 1.1g of hydroquinone, and 0.45g of stannous chloride into a three-necked reaction flask, raise the temperature to 148°C, keep the temperature for 4 hours, and pump Excess methanol was removed in vacuo and cooled to obtain a reactive diluent.

[0035] (3) Weigh 260g of high heat-resistant unsaturated polyester, 190g of hyperbranched polysiloxane, 360g of reactive diluent, 3.24g of BYK-410, 8.5g of...

Embodiment 3

[0037] (1) Weigh 560g of vinyltrimethoxysilane and 31g of deionized water into a three-necked reaction flask, adjust the pH value of the system to 2 with HCl, raise the temperature at 55°C, and react for 3 hours. Add 230g of benzyl alcohol, 0.7g of hydroquinone, and 0.43g of stannous chloride, slowly raise the temperature to 140°C, keep the temperature for 3 hours, vacuumize to remove the remaining methanol, end the reaction, and cool to room temperature to obtain hyperbranched polysiloxane alkyl.

[0038] (2) Add 260g of vinyltrimethoxysilane, 684g of hydroxyethyl methacrylate, 0.95g of hydroquinone, and 0.39g of stannous chloride into a three-necked reaction flask, raise the temperature to 150°C, keep the temperature for 3 hours, and pump Excess methanol was removed in vacuo and cooled to obtain a reactive diluent.

[0039] (3) Weigh 250g of high heat-resistant unsaturated polyester, 170g of hyperbranched polysiloxane, 400g of reactive diluent, 1.28g of DeuRHeo 2810, 2g of BY...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com