High-varnish hanging amount solventless impregnating resin and preparation method thereof

An impregnating resin and solvent-free technology, which is applied in the field of solvent-free impregnating resin with high hanging paint and its preparation, can solve the problems of low loss, environmental pollution, low volatility, etc., and achieve good storage stability, good manufacturability, and high viscosity The effect of high knot strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

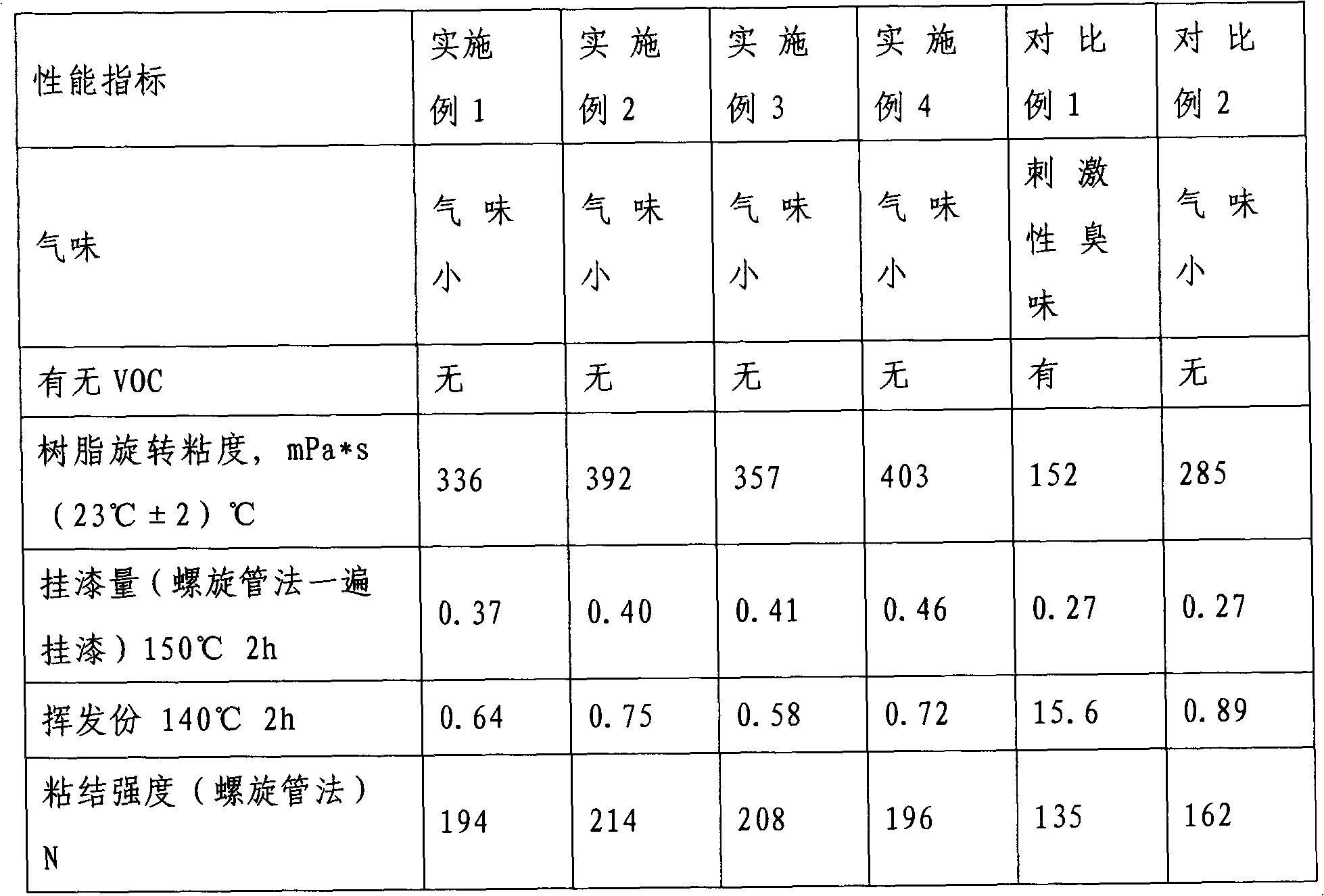

Examples

Embodiment 1

[0037] Weigh 340g of JF-158 into a 500ml three-neck flask, raise the temperature to 105°C, and slowly add 48.2g of acrylic acid solution dropwise, wherein the acrylic acid solution is a mixed solution composed of 45g of acrylic acid, 0.2g of hydroquinone and 0.4g of benzylamine. After about 0.5 hours of the dropwise addition, the temperature was raised to about 120°C, the reaction was carried out until the acid value dropped below 5 mg-KOH / g, and then cooled to room temperature to obtain low-viscosity epoxy acrylate (A).

[0038] Weigh 200g JF-9956, 200g low-viscosity epoxy acrylate (A), 180g 1,6-hexanediol dimethacrylate, 160g 1,4-butanediol dimethacrylate in a 1000ml three-necked flask , heated to 90-120°C, stirred evenly, cooled to 50-60°C, added 8g of zinc isooctanoate, 7.5g of dicumyl peroxide, 0.5g of tert-butylcatechol, stirred evenly, and a solvent-free impregnating resin was obtained.

[0039] Add 7.5g of fumed silica and 3.7g of BYK410 into the solvent-free impregnat...

Embodiment 2

[0041] Weigh 800g of JF-158 into a 2000ml three-neck flask, raise the temperature to 90°C, and slowly add 152.5g of acrylic acid solution dropwise, wherein the acrylic acid solution is a mixed solution consisting of 144g of acrylic acid, 0.5g of hydroquinone and 2.4g of benzylamine. After about 1 hour of dropwise addition, the temperature was raised to about 125°C, and the reaction was carried out until the acid value dropped below 5 mg-KOH / g, and then cooled to room temperature to obtain low-viscosity epoxy acrylate (B).

[0042] Weigh 400g JF-9956, 300g low-viscosity epoxy acrylate (B), 350g propoxylated neopentyl glycol diacrylate, 200g tripropylene glycol diacrylate and 130g 1,4-butanediol dimethyl In a 2000ml three-neck flask, heat up to 90-100°C, stir evenly, cool down to 50-60°C, add 7g of zinc isooctanoate, 13g of dicumyl peroxide, and 0.6g of p-benzoquinone, dissolve evenly, and filter , packaged in solvent-free impregnated resins.

[0043] Add 18g of fumed aluminum ...

Embodiment 3

[0045]Take by weighing 300g JF-9956-1, the low-viscosity epoxy acrylate (B) synthesized by 400g embodiment 2, 400g 1,4-butanediol dimethacrylate and 200g dimethacrylate triethylene glycol Esters, 60g of trimethylolpropane trimethacrylate in a 2000ml three-necked flask, heated to 90-100°C, stirred evenly, cooled to 50-60°C, added 16g of zinc acetylacetonate, 14g of (2-ethyl peroxide ) tert-butyl hexanoate, 0.7g of hydroquinone, dissolved uniformly, filtered, and packaged to obtain a solvent-free impregnated resin matrix. Add 15g of fumed silica and 8g of DeuRHeo 2810 into the solvent-free impregnating resin matrix, and uniformly disperse for 6 minutes under the shearing effect of a homogeneous emulsifier at a line speed of 13m / s. Filtered, packaged high hang paint solvent free impregnation resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com