Indirect water cooling device for oriented silicon steel high-temperature annular furnace

A technology of water cooling device and oriented silicon steel, applied in furnace cooling devices, furnaces, heat treatment furnaces, etc., can solve the problems of slow cooling speed, hindering the production output of silicon steel, and large constraints, so as to improve cooling speed, good application prospects, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

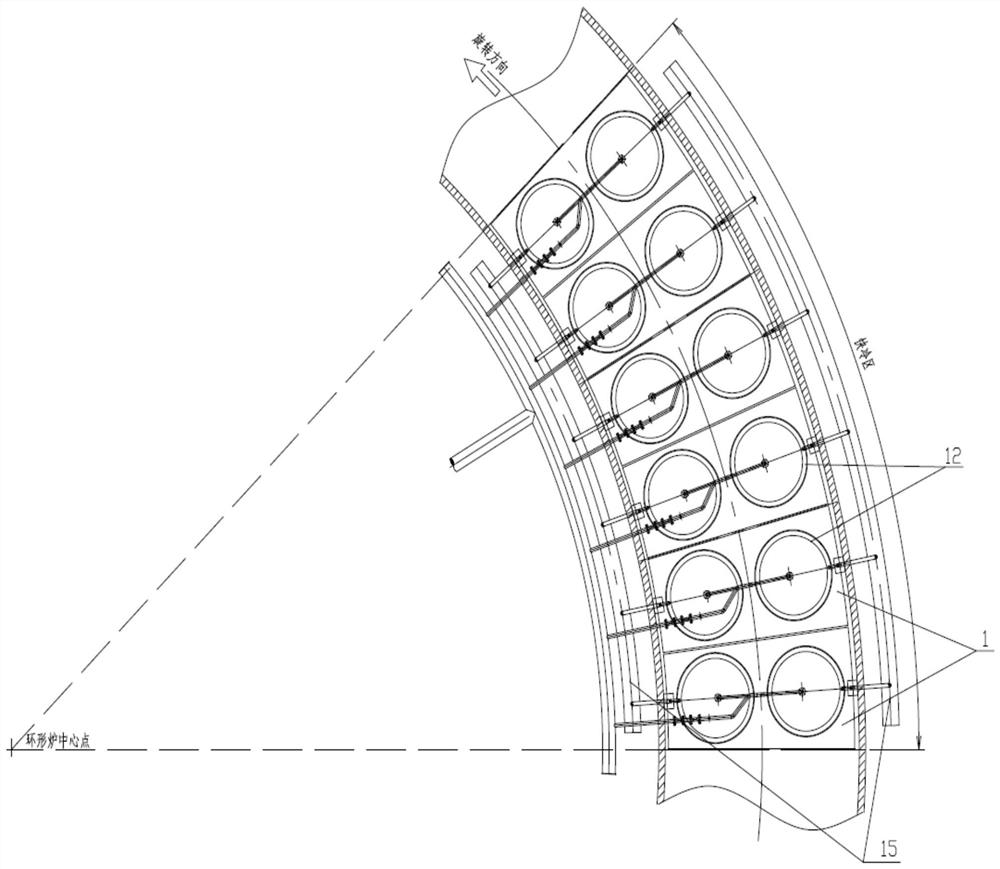

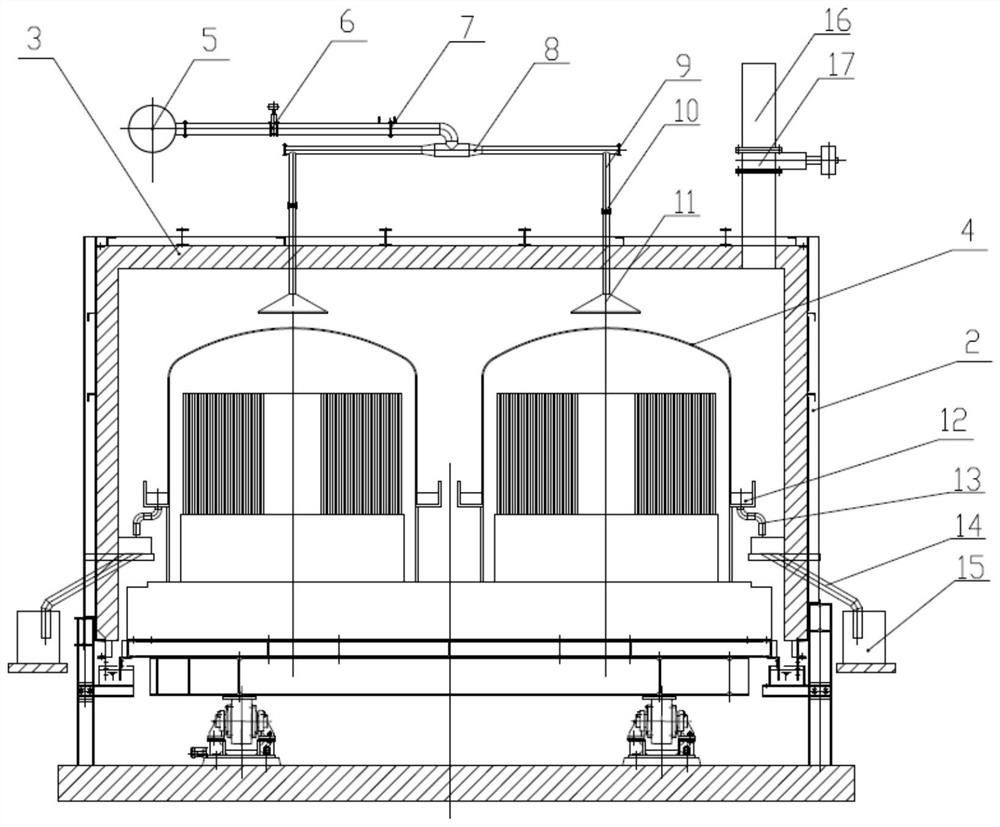

[0012] The silicon steel annular furnace cooling device of the present invention will be described below in conjunction with the accompanying drawings.

[0013] The present invention comprises a cooling water main pipeline 5, a cooling water section pipeline 8, a cooling water branch pipeline 9, an inner cover 4, a spraying device 11, a water collection tank 12, a drainage pipe 13, a water diversion tank 14, a water tank 15, a steam discharge pipe 16, The discharge valve 17 and accessories form a complete spray cooling system.

[0014] The cooling water main pipe 5 is used to supply water to the cooling zone of the annular furnace, which is fixed on the steel structure of the annular furnace roof 3, either inside or outside, and is about 400mm higher than the furnace roof 3, and is made of carbon steel pipes. The number of hearths 1 in the cooling zone, usually the number of hearths in the cooling zone of the silicon steel annular furnace is 6 to 8 sets, and a corresponding nu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap