Preparation method of full dull polyester fiber hygroscopicity and perspiration silk fiber raschel blanket

A raschel blanket, silk fiber technology, applied in the direction of dyeing, heating/cooling fabric, roughening, etc., can solve the problems of inability to meet the diverse needs of consumers, poor use comfort, poor moisture wicking performance, etc. , to achieve the effect of good moisture absorption and quick drying performance, good printing quality and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

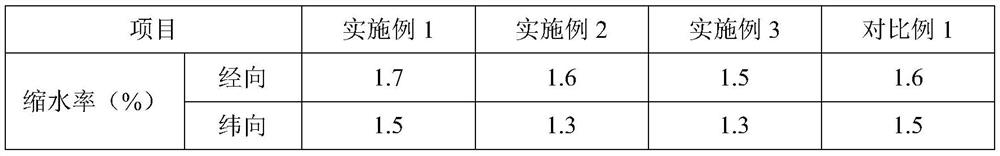

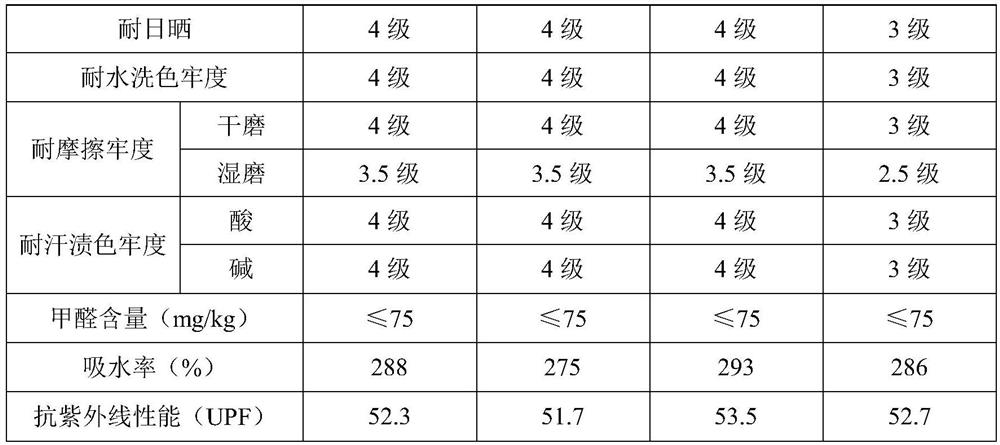

Embodiment 1

[0044] A method for preparing a Raschel blanket of Fidelon suction and discharge silk fiber, comprising the following steps:

[0045] (1) Weaving: use DTY300D / 96f Fidelity fiber as plush yarn, 150D / 36f polyester full-drawn yarn as bottom yarn, use GE2888 high-speed double-needle bed warp knitting machine, the speed is 590 rpm, let-off The method adopts electronic warp let-off, and the gauge is 18mm, and weaves on a high-speed warp knitting machine by adopting the method of full-threading three-needle and four-needle weft inlay in the same direction to obtain gray cloth;

[0046] (2) Pre-finishing: the gray cloth is scalded first and then pre-set to obtain the gray cloth after pre-finishing; when ironing, it is firstly pre-scalded against the wool, then combed along the wool, and finally alternately ironed against the wool Light; the pre-scalding temperature of reverse wool is 203℃, and the speed is 17m / min; / min, the ironing roller uses W groove; the predetermined temperature...

Embodiment 2

[0057] A method for preparing a Raschel blanket of Fidelon suction and discharge silk fiber, comprising the following steps:

[0058] (1) Weaving: Use DTY300D / 96f Fidelity fiber as plush yarn, 150D / 36f polyester full-drawn yarn as base yarn, use GE2888 high-speed double-needle bed warp knitting machine, the speed is 580 rpm, let-off The method adopts electronic warp let-off with a gauge of 17mm, and weaves on a high-speed warp knitting machine by adopting the method of full-threading three-needle and four-needle weft padding in the same direction to obtain gray cloth;

[0059] (2) Pre-finishing: the gray cloth is scalded first and then pre-set to obtain the gray cloth after pre-finishing; when ironing, it is firstly pre-scalded against the wool, then combed along the wool, and finally alternately ironed against the wool Light; the pre-scalding temperature of reverse wool is 200℃, the speed is 16m / min; the high combing speed of smooth wool is 16m / min; the alternate scalding of ...

Embodiment 3

[0070] A method for preparing a Raschel blanket of Fidelon suction and discharge silk fiber, comprising the following steps:

[0071] (1) Weaving: use DTY300D / 96f Fidelity fiber as plush yarn, 150D / 36f polyester full-drawn yarn as base yarn, use GE2888 high-speed double-needle bed warp knitting machine, the speed is 600 rpm, let-off The method adopts electronic warp let-off, and the gauge is 19mm, and weaves on a high-speed warp knitting machine by adopting the method of full-threading three-needle and four-needle weft inlay in the same direction to obtain gray cloth;

[0072] (2) Pre-finishing: the gray cloth is scalded first and then pre-set to obtain the gray cloth after pre-finishing; when ironing, it is firstly pre-scalded against the wool, then combed along the wool, and finally alternately ironed against the wool Light; the pre-scalding temperature of reverse wool is 205℃, and the speed is 18m / min; the high combing speed of smooth wool is 18m / min; / min, the ironing rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com