Automatic replacement equipment for railway sleeper

A technology for automatic replacement of railway sleepers, which is applied to roads, track laying, track superstructure, etc. It can solve problems such as low work efficiency, traffic accidents, and high labor intensity, so as to avoid waste of manpower and material resources and improve practical performance and efficiency. , The effect of simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

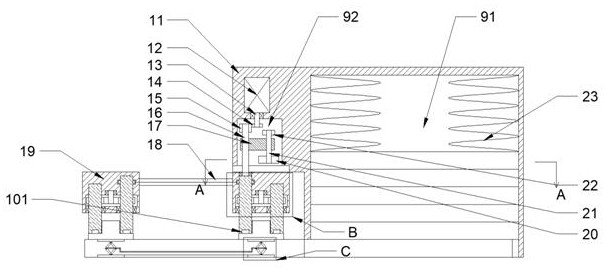

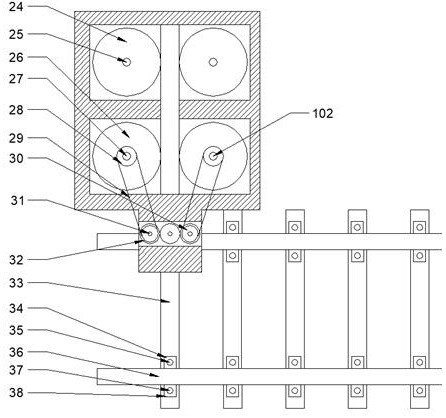

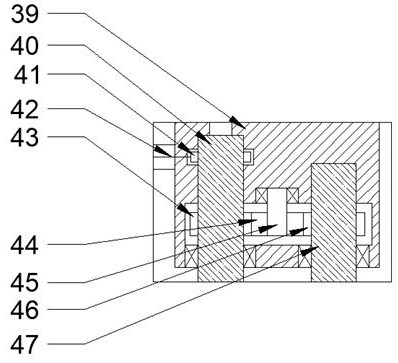

[0015] Combine below Figure 1-4 The present invention is described in detail, wherein for the convenience of narration, the orientations mentioned below are stipulated as follows now: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0016] combined with Figure 1-4 The automatic railway sleeper replacement equipment includes a fuselage 11 and a packing chamber 91 provided inside the fuselage 11, a transmission chamber 92 is provided inside the fuselage 11 on the left side of the filler chamber 91, and the transmission The top of the cavity 92 is fixedly provided with a motor 12 in the body 11, and a motor shaft 13 is rotatably arranged in the motor 12, and a motor gear 14 is fixedly connected to the bottom of the motor shaft 13, and the left end of the motor gear 14 is connected to The wide gear 15 meshes, the wide gear 15 is fixedly connected to the top of the first rotating shaft 16, the first rotating sha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap