Fabricated type concrete-filled steel tube supporting system and construction method thereof

A technology of steel pipe concrete and support system, which is applied in excavation, infrastructure engineering, construction, etc., and can solve the problems of restricting the construction progress on site, non-conformity, and non-environmental protection, etc., and achieves the convenience of factory production, convenient installation and disassembly, and easy circulation The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

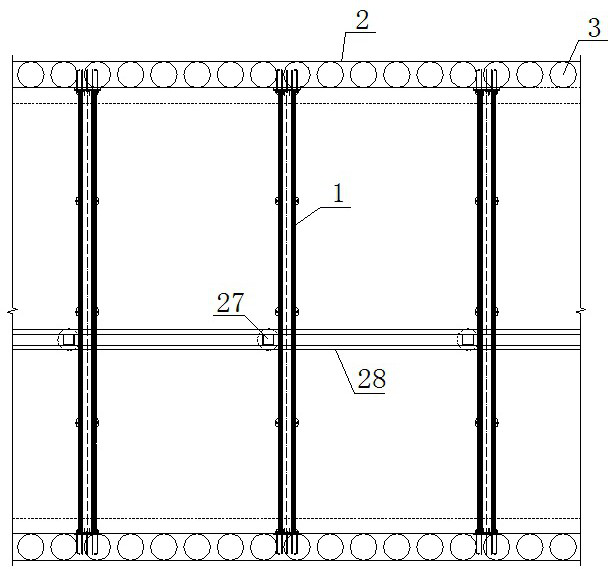

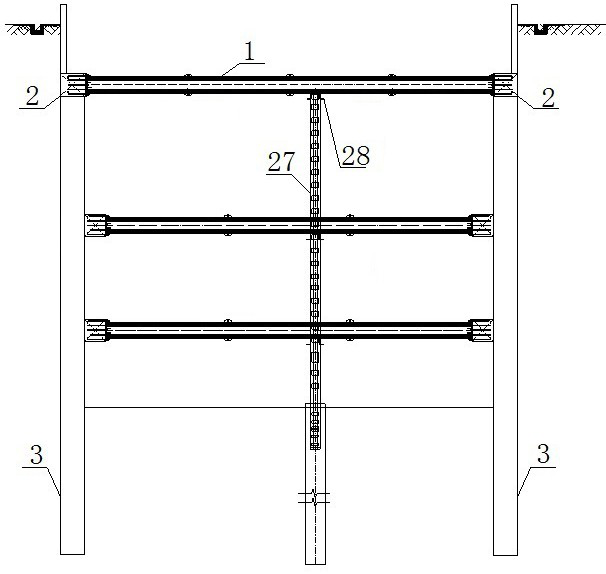

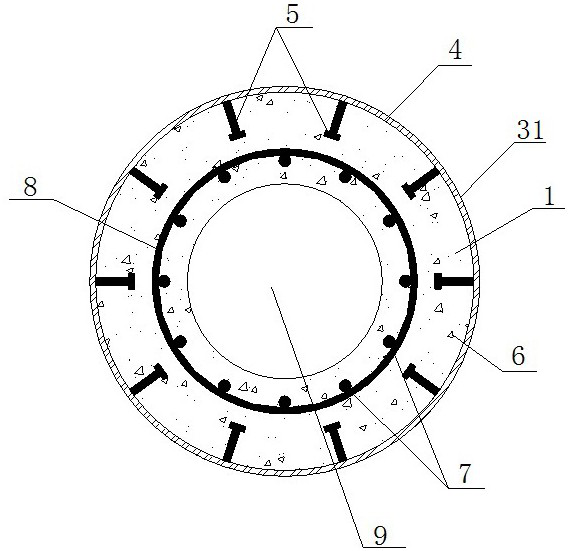

[0055] This embodiment provides a prefabricated concrete-filled steel tube support system, including an enclosure structure 3 and an assembled concrete-filled steel tube support; the top of the enclosure structure 3 is provided with a crown beam 2 , and the The prefabricated steel pipe concrete support is supported by the assembled steel pipe concrete support, which is spliced by a plurality of steel pipe concrete support prefabricated parts 1; The end and the supporting components on both sides are respectively connected by telescopic connectors. The prefabricated steel tube concrete support used in the support system of this embodiment is spliced by multiple steel tube concrete support prefabricated parts 1, and the fabricated steel tube concrete support is detachably connected to the support components in the crown beam 2 through telescopic connectors. Not only is it convenient to assemble and disassemble, but it is also convenient for the recycling of components; and t...

Embodiment 2

[0076] This embodiment provides a construction method for a prefabricated steel pipe concrete support system, including the following steps:

[0077] S1. According to the design drawings, the steel pipe concrete support prefabricated part 1, the construction envelope structure 3 and the lattice column 27 are manufactured in the factory;

[0078] S2. Transport the prefabricated steel tube concrete support 1 to the construction site, and splice the bolts 11 to form the fabricated steel tube concrete support;

[0079] S3, the first U-shaped steel plate 20 is welded to the first end steel plate 18, the anchor bolt 17 passes through the support steel plate 29 with the support leg 30 at the bottom and the first end steel plate 18 in turn, and is fixed by the nut 19;

[0080] S4. Weld the second U-shaped steel plate 21 and the second end steel plate 32, and then fix the second end steel plate 32 and the end of the fabricated steel pipe concrete support with bolts 11;

[0081] S5, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com