Detachable prefabricated building wall and dismounting and mounting device thereof

A technology for building walls and prefabricated walls, applied in construction, building maintenance, building components, etc., can solve the problems of reducing the disassembly and assembly efficiency of prefabricated walls, limiting the installation and disassembly efficiency of prefabricated walls, and consuming manpower. The effect of installing prefabricated walls in sequence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

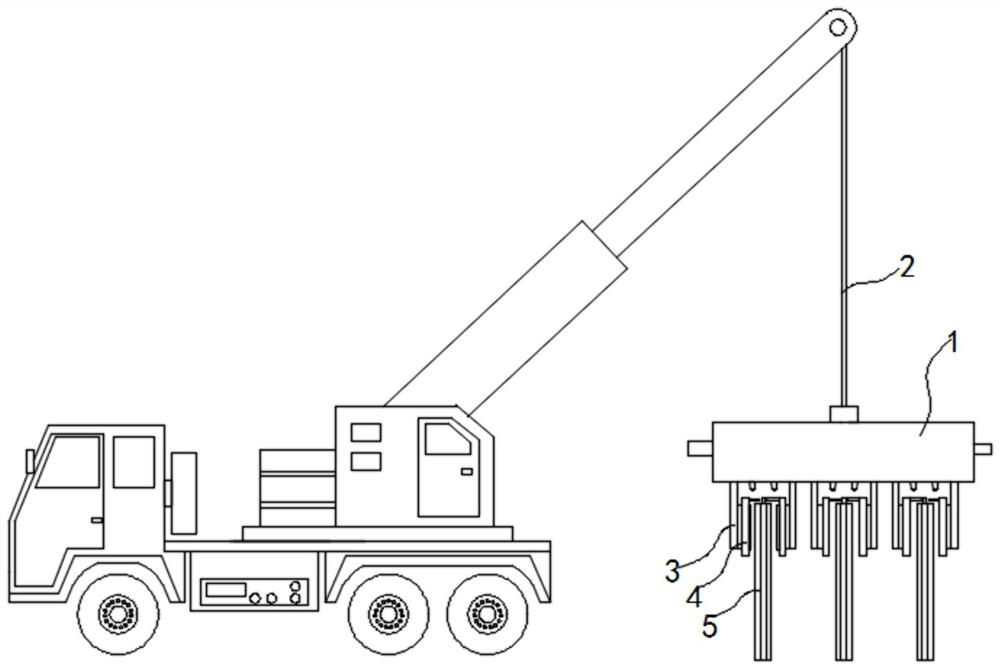

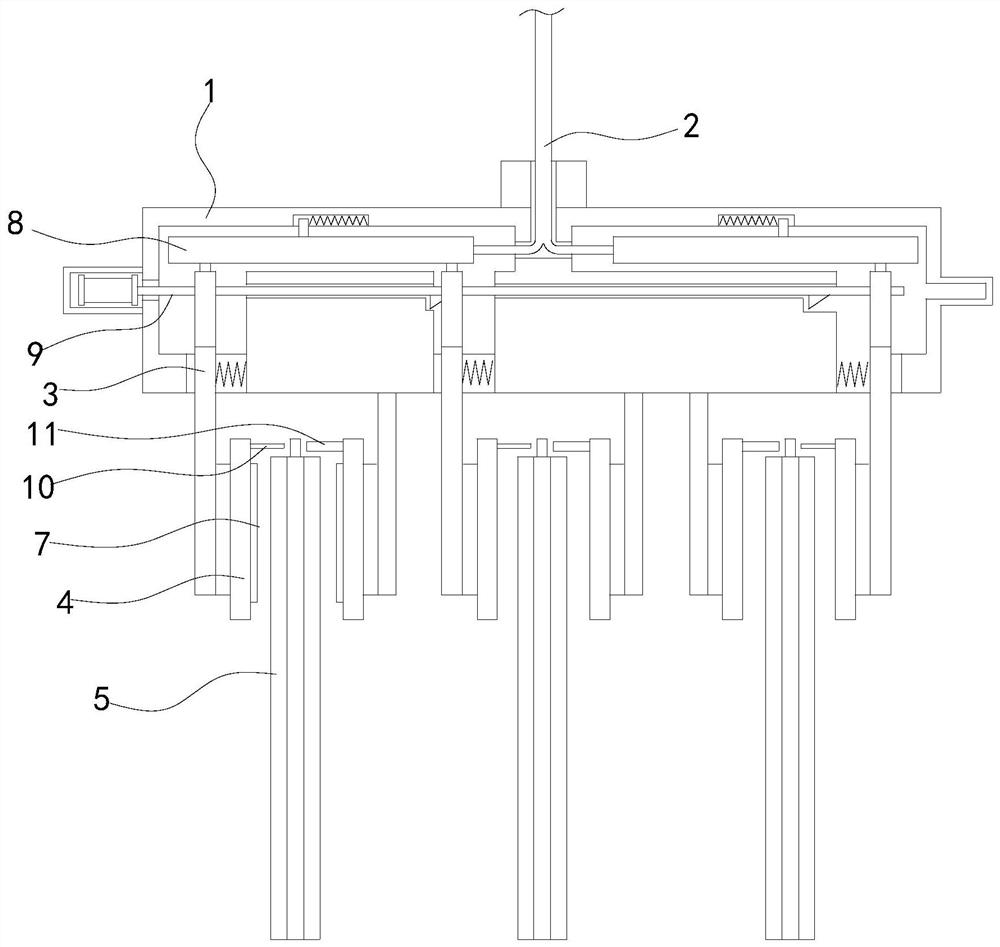

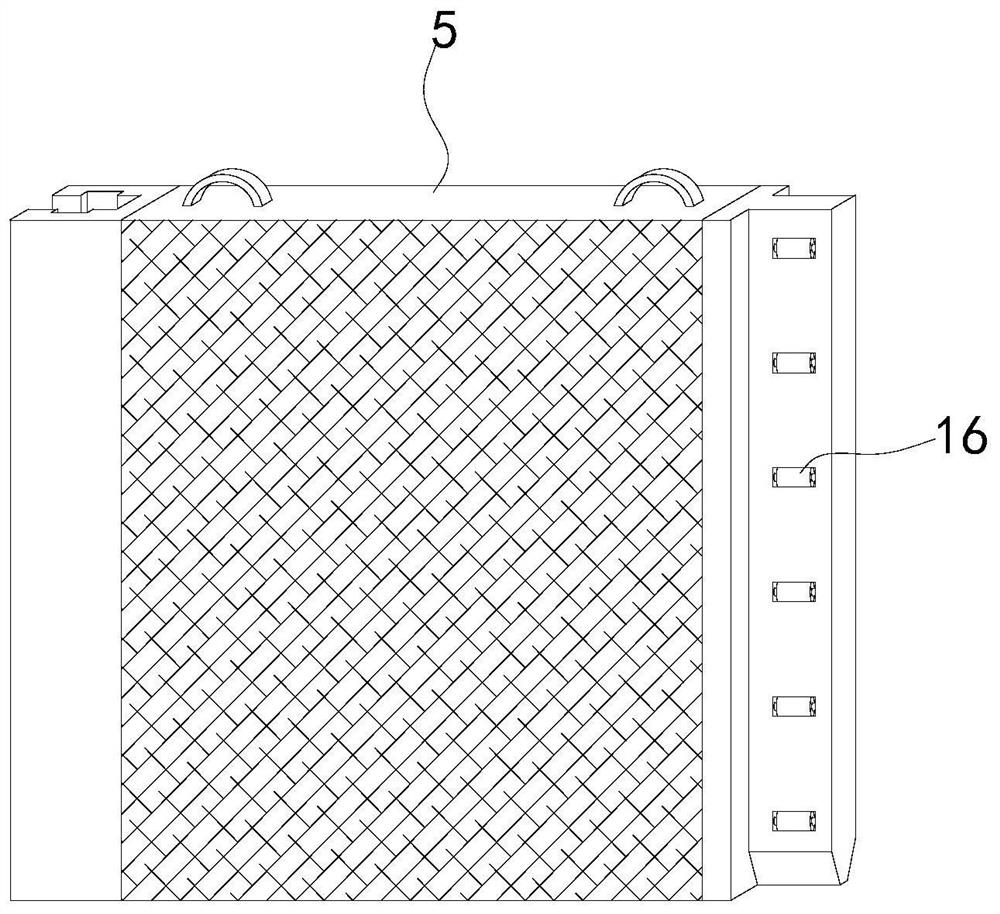

[0024] see Figures 1 to 6 , a schematic diagram of a planar structure and a schematic diagram of a three-dimensional structure of a detachable prefabricated building wall and its disassembly equipment.

[0025] A device for disassembling and assembling a prefabricated building wall, comprising a disassembling device 1 and a sling 2, a clamping device 3 is movably installed on the lower end of the disassembling device 1, and a prefabricated wall 5 is movably installed on the inner side of the clamping device 3 The upper end of the disassembly device 1 is movably equipped with a drive plate 8 , the middle end of the disassembly device 1 is movably equipped with a moving rod 9 , and the upper end of the clamping device 3 is movably equipped with a snapping block 13 .

[0026] In specific implementation, the upper end of the occlusal block is fitted inside the drive plate, one end of the drive plate is connected to the sling, and two symmetrically arranged clamping devices are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com