Rotor blade tip clearance control method and rotor blade manufactured by the method

A technology of rotor blade and control method, applied in the field of rotor blade tip clearance control and rotor blade field, can solve the problem of uneven radial displacement of rotor blade tip, and achieve the effect of improving aerodynamic performance parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

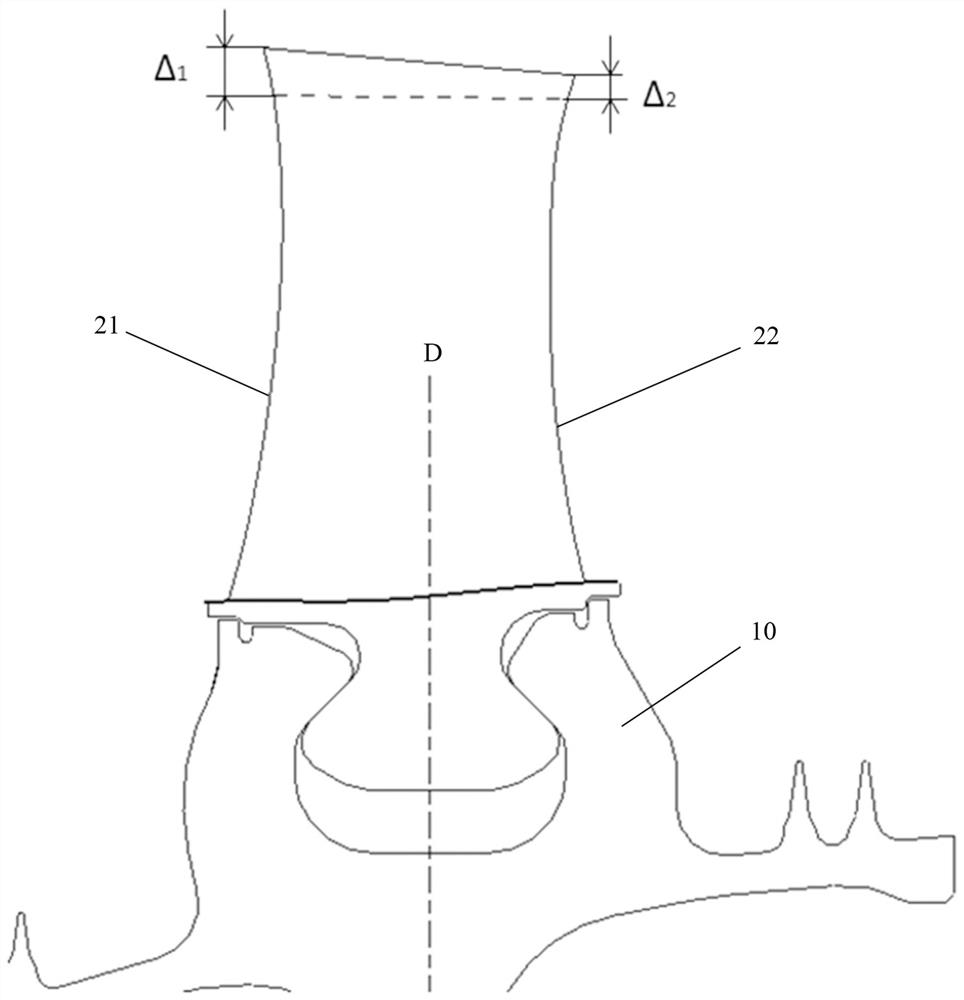

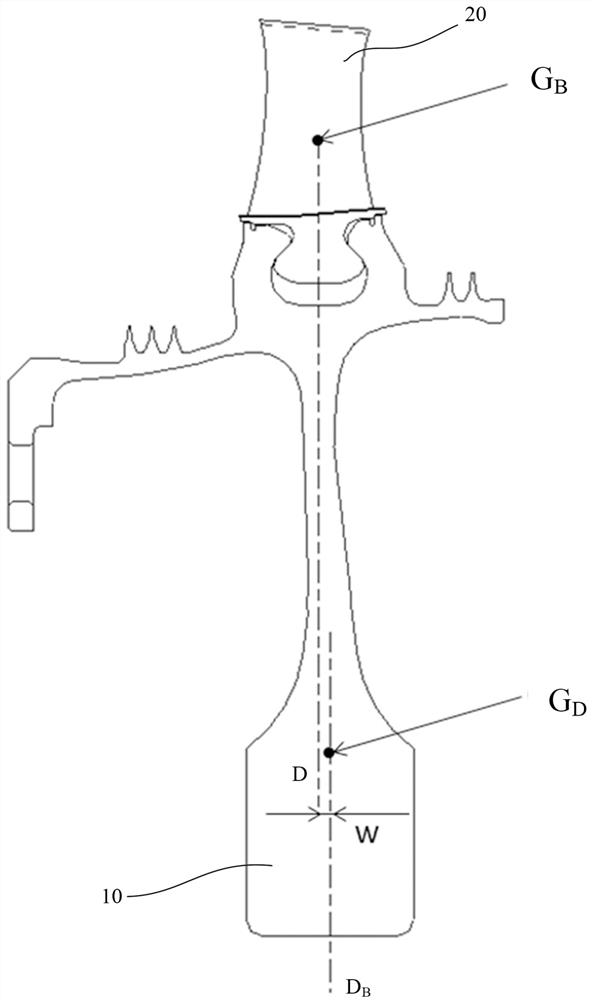

[0059]The steps of the rotor blade tip clearance control method according to the present invention, as well as the structure and effect of the rotor blade manufactured by the method will be described below with reference to the accompanying drawings, wherein the same components are marked by the same reference numerals.

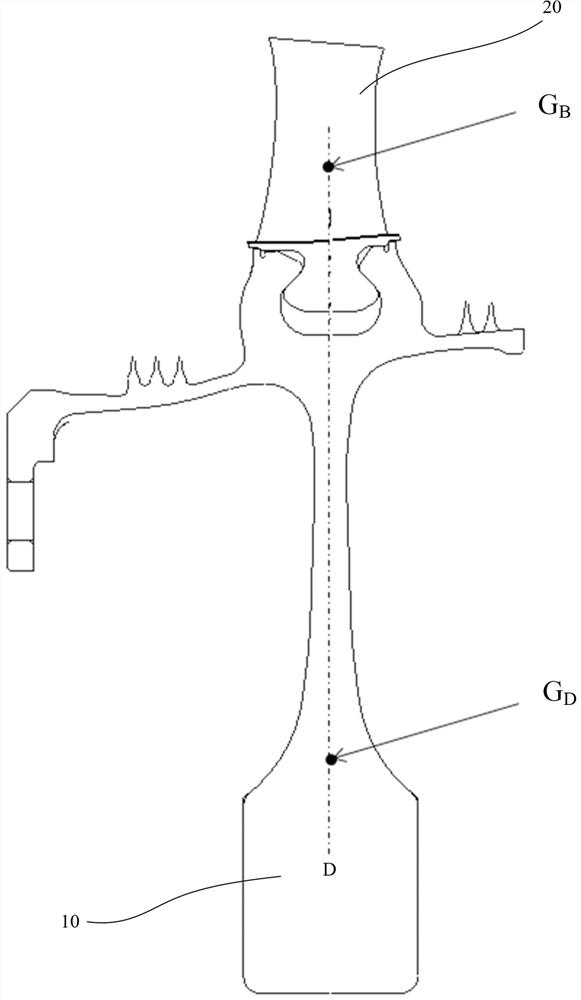

[0060] figure 1 A rotor disk 10 with an unshifted center of gravity is shown, on which several rotor blades 20 are mounted, and for ease of illustration, only one rotor blade 20 is shown in this figure.

[0061] As we all know, the rotating body supported by bearings during high-speed rotation is called a rotor, and the rotor is the main rotating part in the field of power machinery such as electric motors, generators, gas turbines, turbocompressors and compressors. The rotor can rotate around its axis, the extending direction of the axis is called the axial direction of the rotor, and the direction extending radially from the axis vertically is called the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com