Hydraulic control system

A hydraulic cylinder and oil circuit technology, applied in the application field of flexible mechanisms in hydraulic systems, can solve problems such as increasing strength, difficulty in achieving buffer support, and single-effect force provision, and achieve the effect of strong buffer capacity and strong support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

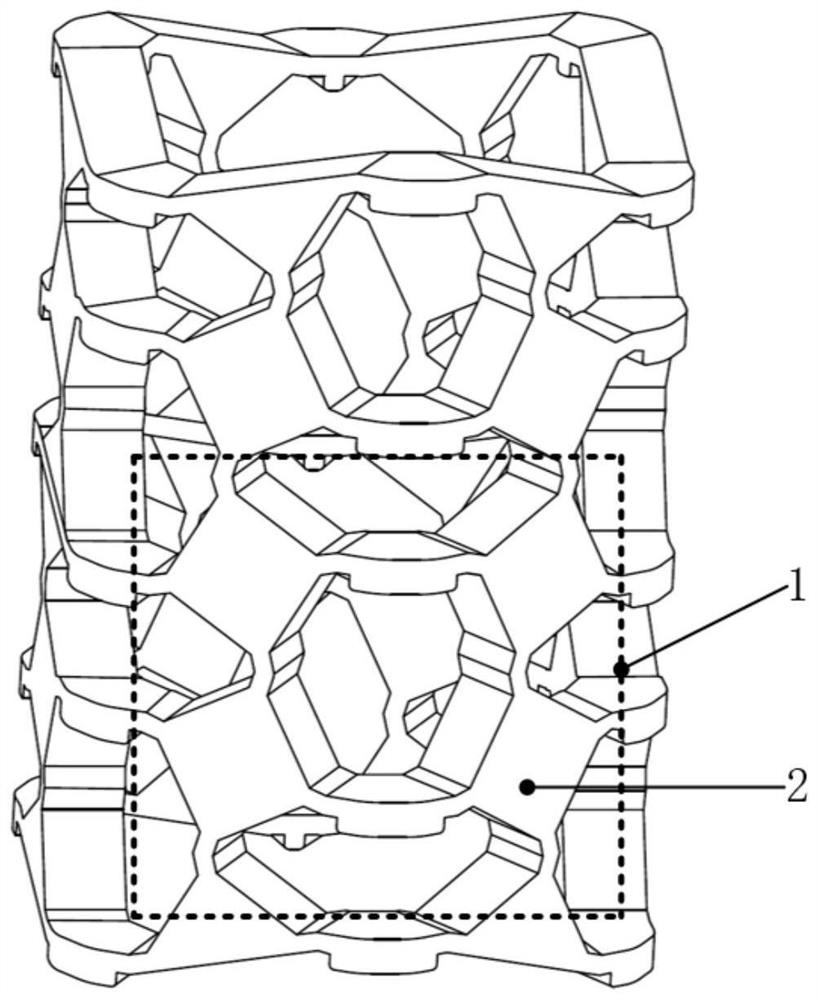

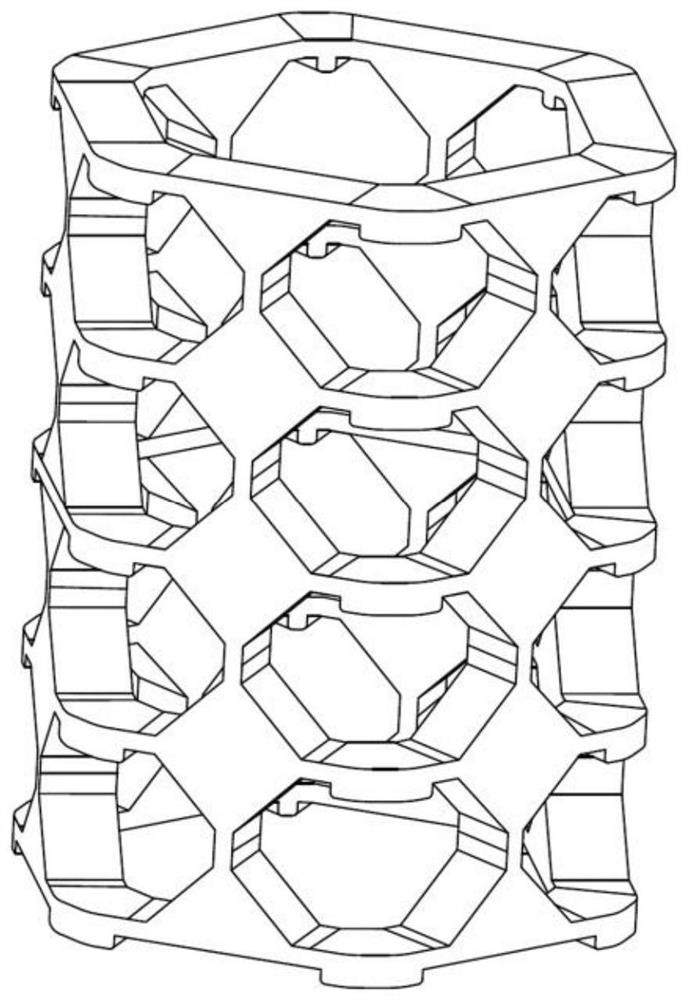

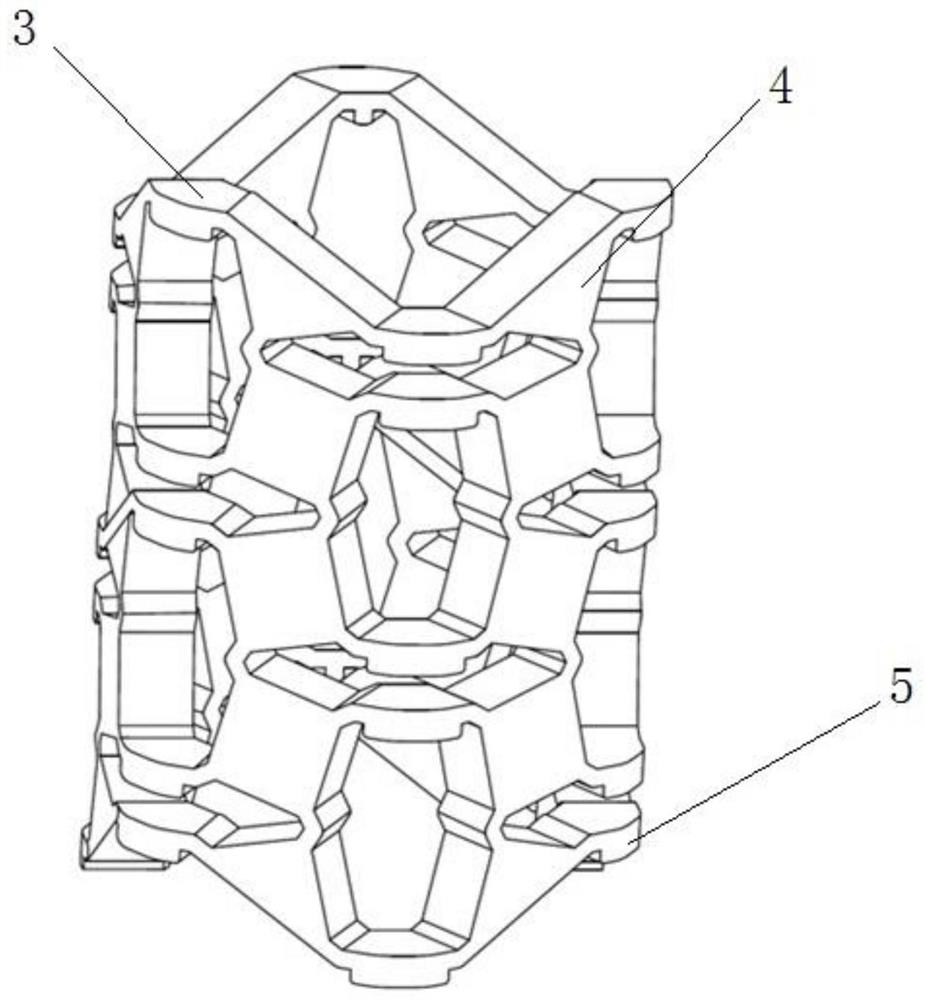

[0050]As shown in the figure: a hydraulic control system, including: fuel tank 13, oil pump 14, filter 15, overflow valve 16, first solenoid valve 17, second solenoid valve 18, third solenoid valve 19, fourth solenoid valve 20. Check valve 21, first hydraulic cylinder 22, second hydraulic cylinder 23, third hydraulic cylinder 24;

[0051] Fuel tank 13, filter 15, oil pump 14, and check valve 21 are connected in sequence to form an oil delivery circuit; the downstream of check valve 21 is provided with a first oil circuit and a second oil circuit, and a first solenoid valve 17 is provided on the first oil circuit. A second electromagnetic valve 18 is arranged on the second oil circuit, the first oil circuit connects one end of the first to the third hydraulic cylinder, the second oil circuit connects the other end of the first to the third hydraulic cylinder; the first oil circuit connects the first The oil return circuit, the second oil circuit is connected with the second oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com