Method for detecting gas content of oil sample

A detection method and gas content technology, applied in sampling devices, analysis materials, instruments, etc., can solve the problems of low work efficiency, expensive instruments, and only one sample can be detected, and achieve the effect of labor saving and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

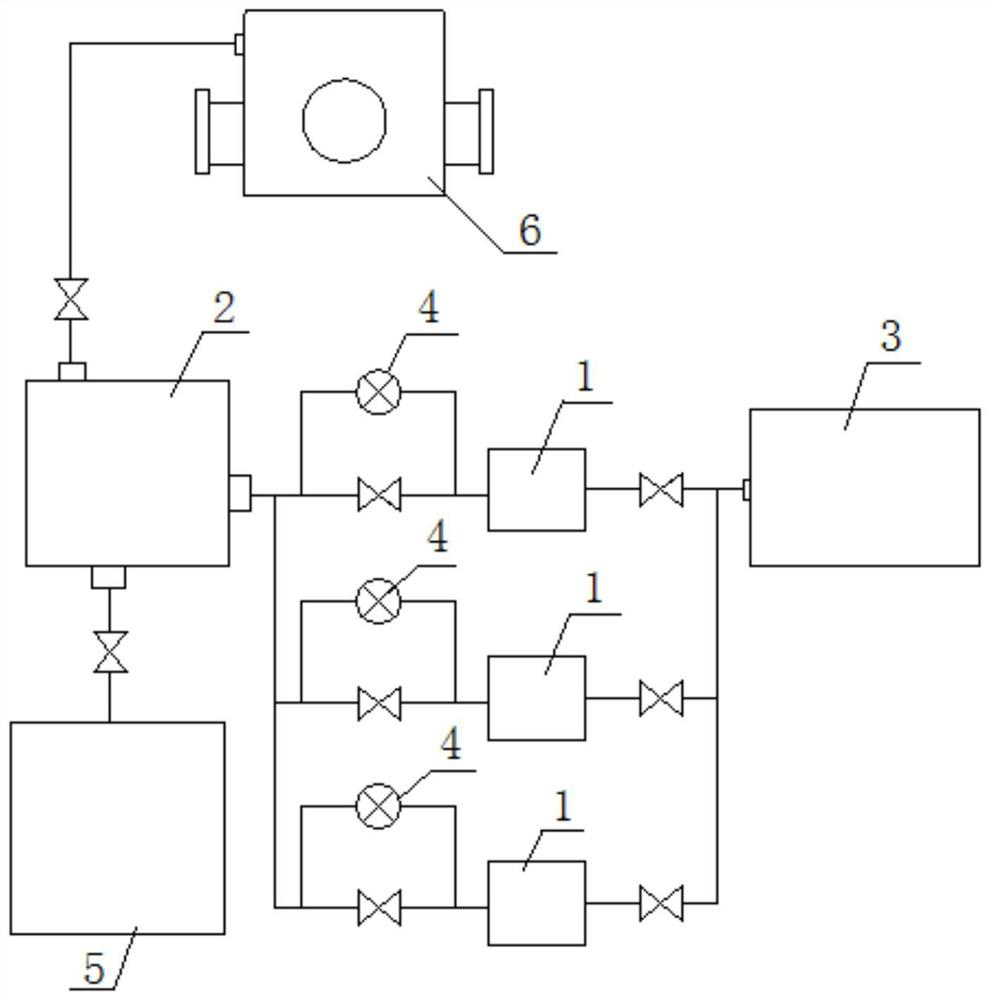

[0028] Such as figure 1 Shown, a kind of oil sample gas content detection method comprises the following steps:

[0029] S1. Preparation equipment: sealed container 1, quantitative sampler 2, vacuum device 3, vacuum degree measuring device 4, waste oil collector 5;

[0030] S2. Equipment connection: the oil valve of the transformer 6 is connected to the oil inlet of the quantitative sampler 2 through the oil pipe, the oil discharge port of the quantitative sampler 2 is connected to the waste oil collector 5 through the oil pipe, and the oil outlet of the quantitative sampler 2 is connected to There are multiple branch pipes, each branch pipe is connected to the oil inlet of a vessel 1 respectively, and the air vent of each vessel 1 is connected to the same vacuum device 3 through the oil pipe, and valves are installed on each oil pipe and branch pipe; Both sides of the valve of each branch pipeline are connected with a vacuum measuring device 4;

[0031] S3. Sampling: before...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com