Pipe jacking attitude prediction method based on roller measurement

A prediction method and roller technology, applied in earthwork drilling, design optimization/simulation, special data processing applications, etc., can solve the problem of not considering the impact of jack retraction on mileage, segment attitude without correction guidance, pipe jacking attitude Predict problems such as poor versatility to improve system accuracy and applicability, improve construction quality, and facilitate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

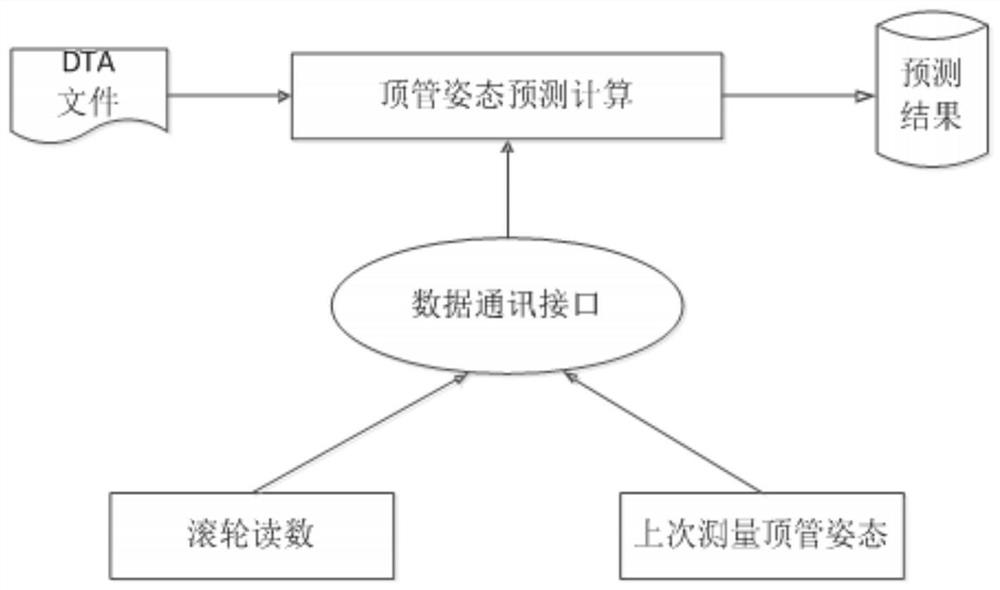

[0043] see figure 1 As shown, the present invention provides a method for predicting the attitude of pipe jacking based on roller measurement, comprising the following steps:

[0044] (1) Measure the incision coordinates (X 切 , Y 切 ,Z 切 ), shield tail coordinates (X 尾 , Y 尾 ,Z 尾 ), and use the roller counting method to count the pipe jacking mileage C in the previous stage 滚轮 ;

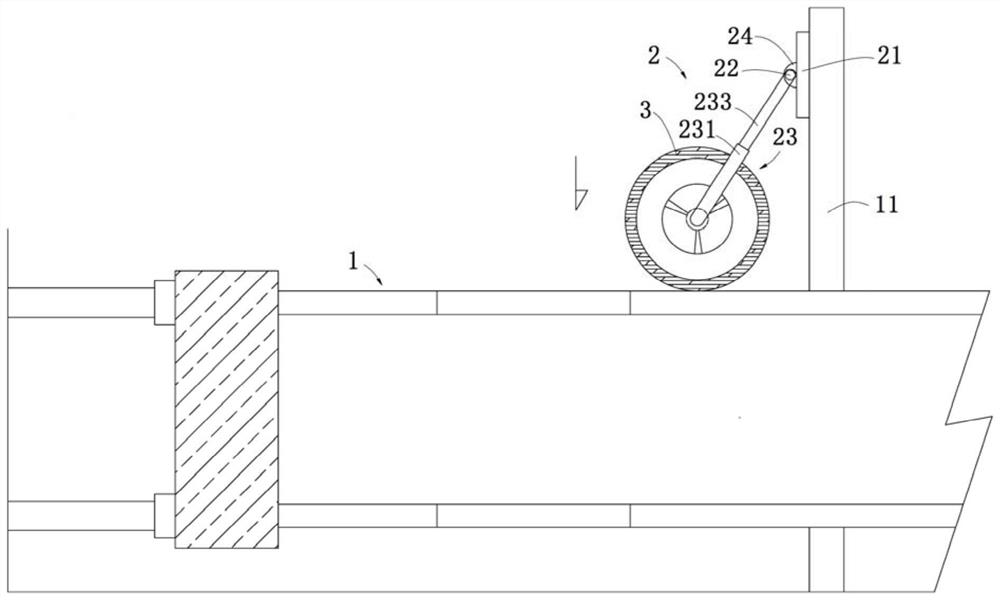

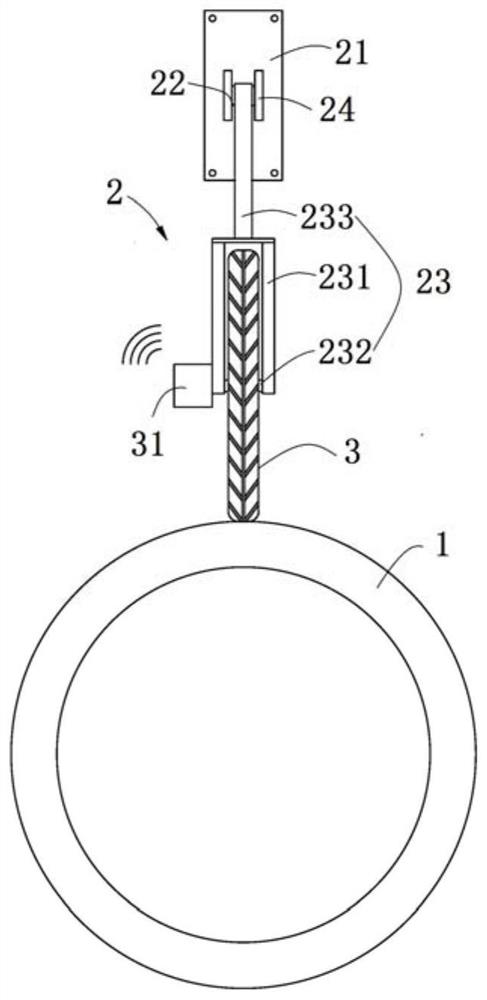

[0045] Such as figure 2 , image 3 As shown, the roller counting method is used to count the pipe jacking mileage C 滚轮 The steps include:

[0046] A roller positioning mechanism 2 is installed on a fixed reference object (such as a wall 11) other than the pipe jacking machine 1, and the roller 3 is movably connected with the roller positioning mechanism 2, and the rolling surface of the roller 3 is pressed against the pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com