Method for on-site drying of motor

A drying method and drying technology, applied in the field of on-site drying of motors, can solve problems such as lack of pertinence, single drying method of motors, and unsatisfactory efficiency, and achieve the effect of ensuring quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

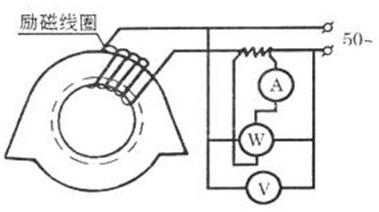

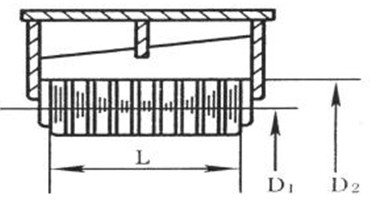

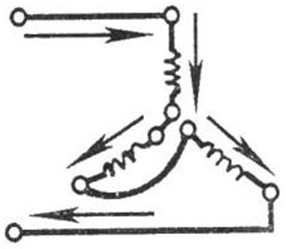

[0041] Such as Figure 1-5 As shown, the embodiment of the present invention provides a method for on-site drying of motors, including the following drying methods: hot air drying, short-circuit current drying, iron loss drying, copper loss drying, and load drying.

[0042] Wherein hot air drying comprises the following steps:

[0043] S1. Install a blower to blow air into a heater. The capacity of the heater is determined according to the motor specification. The motor is covered with canvas, and an exhaust hole is left. The commonly used heater is a heating wire or a steam snake. shaped tube for heating;

[0044] S2. Wait until the air is heated to 70°C-100°C before blowing into the motor to ensure that the air can flow freely through the motor.

[0045] The formula for calculating the capacity of the heater is: Where pN is the rated power of the motor to be dried.

[0046] If the motor and the rotor are dried together, in the drying process, in order to prevent the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com