High-reliability household vegetable pulverizer

A reliable, pulverizer technology, used in household machinery, household appliances, applications, etc. for filtering food, which can solve the problems of food residue splashing on the inner wall, lowering, and inability to fully pulverize.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

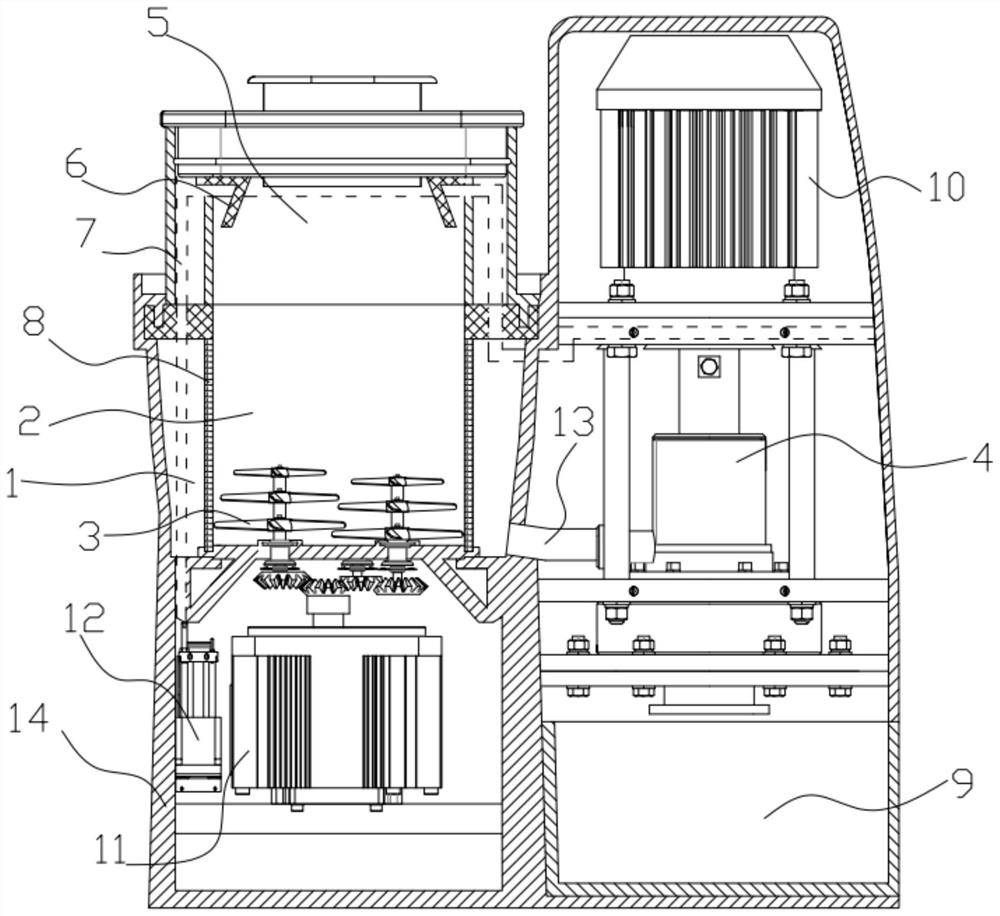

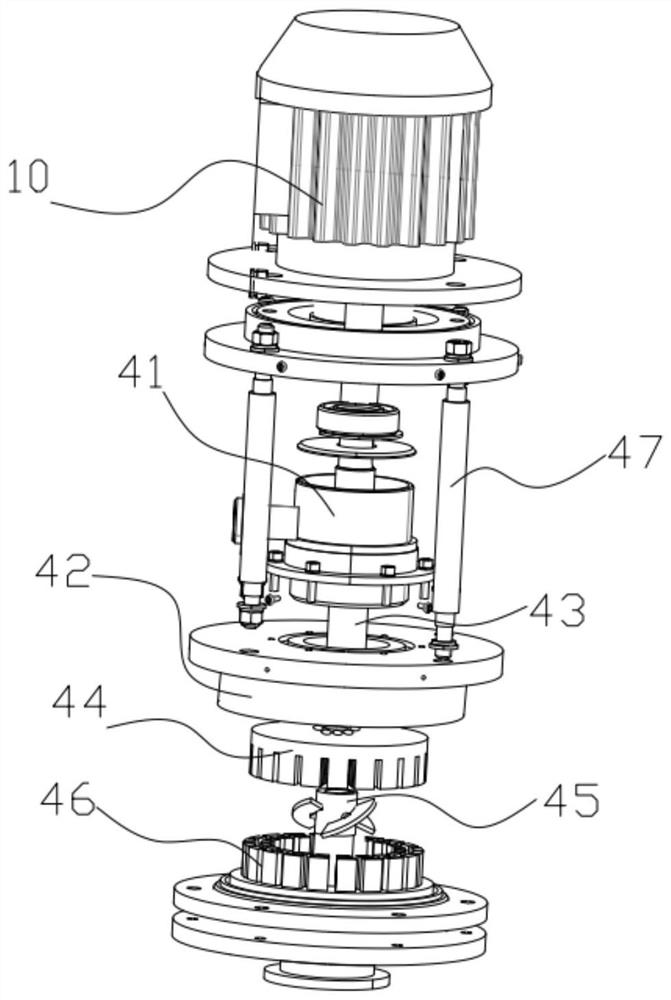

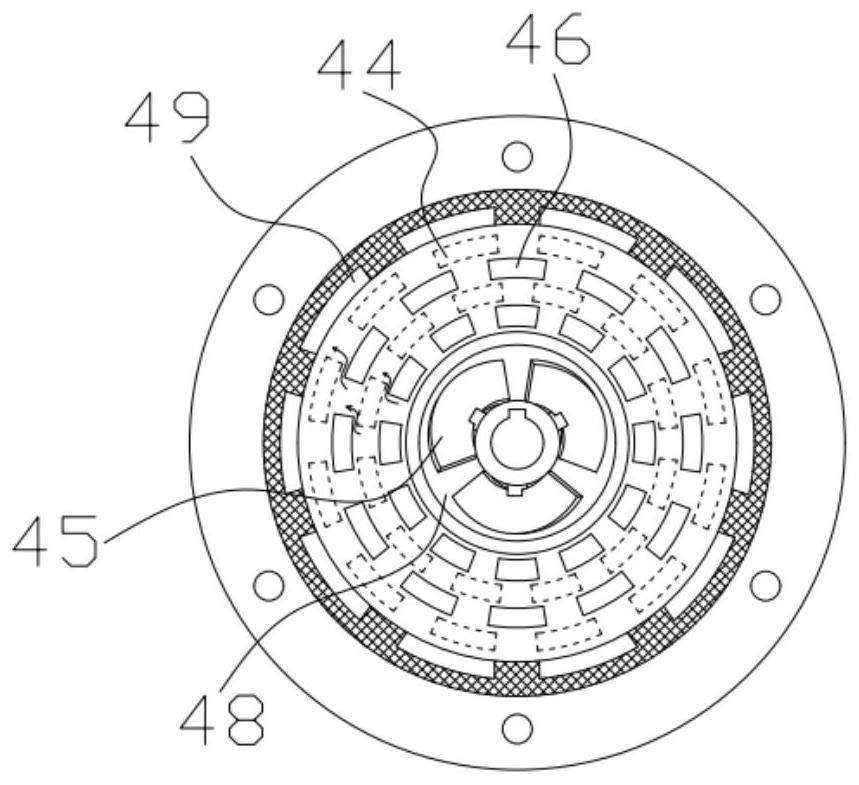

[0028] see figure 1 , in an embodiment of the present invention, a high-reliability household vegetable shredder includes a body 14, a crushing chamber 2, a crushing cutter head 3, and an emulsifying assembly 4, wherein the body 14 is two cylinders connected together on the left and right The left side of the cavity is a crushing cavity 2. A detachable feed cover 5 is arranged above the crushing cavity 2. There are two groups of crushing cutter heads 3 with opposite rotation directions at the bottom of the crushing cavity 2. The surrounding of the crushing chamber 2 is a detachable filter screen 8, the juice chamber 1 is between the filter screen 8 and the body 14, and the lower end of the juice chamber 1 is connected with the emulsification component 4 arranged in the right side chamber of the body 14 through a pipe 13 ;

[0029] The emulsification component 4 can suck the juice in the juice chamber 1 and break the fibers, cell walls, etc. therein;

[0030] A extractable ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com