Automatic material carrying gripper mechanism

An automatic claw and material hand technology, applied in the direction of manipulators, conveyor objects, program-controlled manipulators, etc., can solve the problems of inconvenient adjustment of the height of mechanical claws, and achieve the effects of improving handling efficiency, avoiding falling off, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

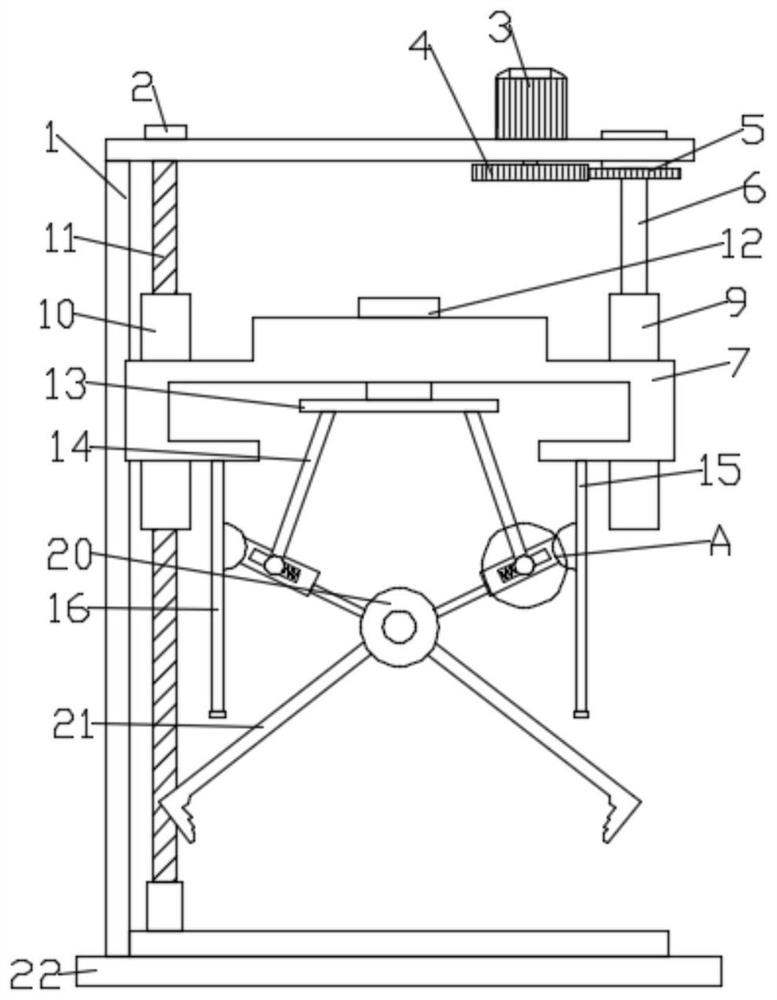

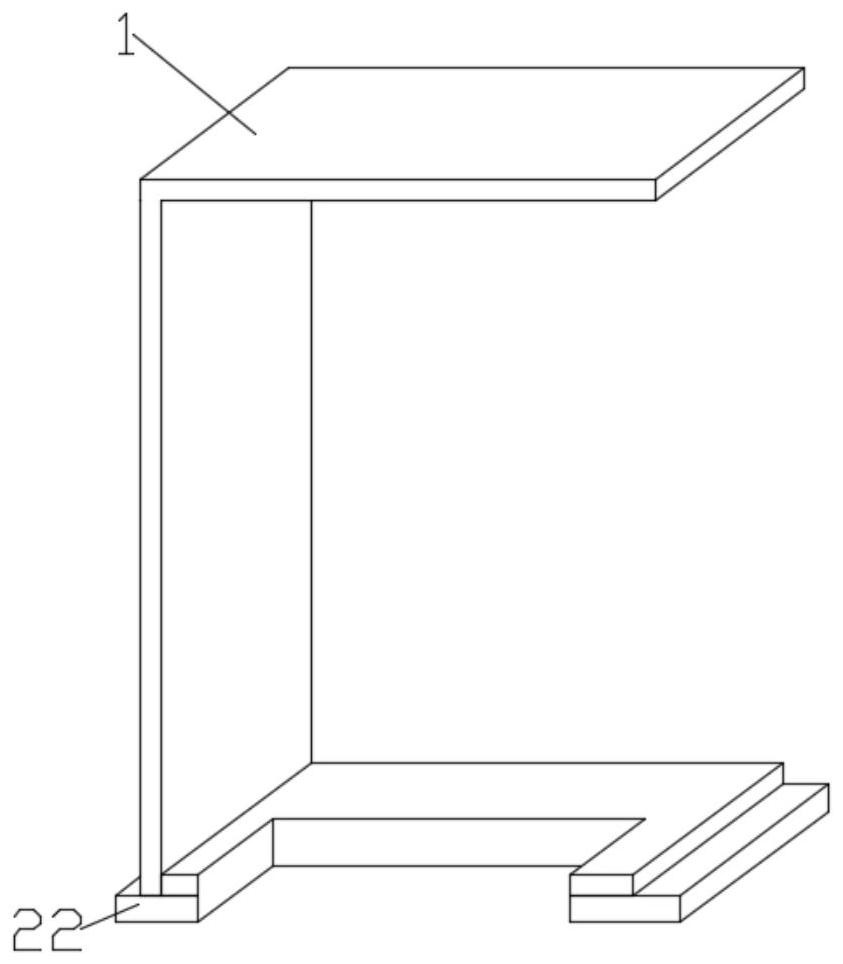

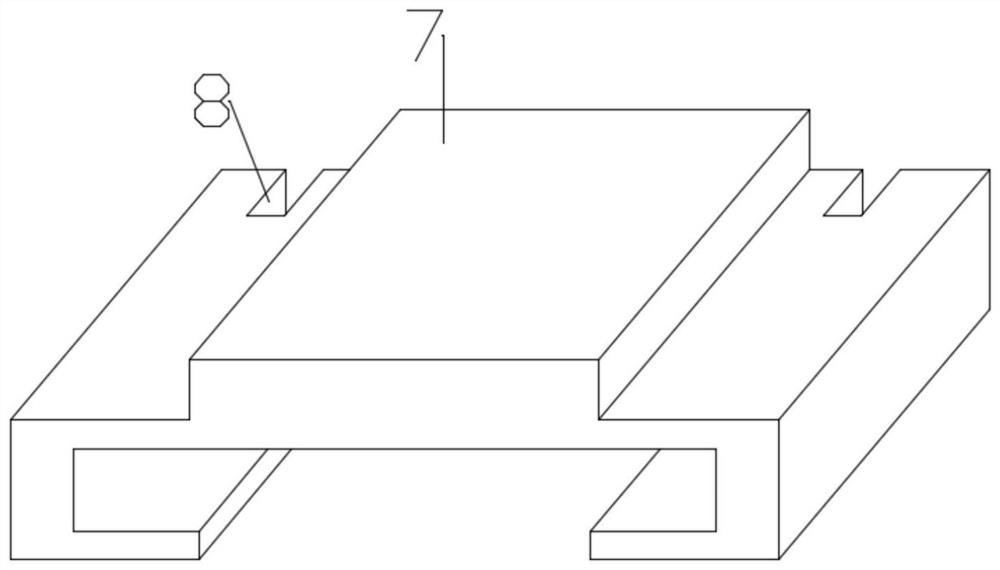

[0024] Such as Figure 1-2 As shown, in the embodiment of the present invention, an automatic claw handling hand mechanism includes a support frame 1 and a base 22, the upper part of the base 22 is fixedly equipped with a support frame 1, and the top of the support frame 1 is fixedly equipped with a horizontal horizontal plate 2, The support frame 1 is provided with a lifting seat 7, and a clamping mechanism 15 for moving materials is installed on the lifting seat 7, and a height adjustment assembly for adjusting the height of the clamping mechanism 15 is also installed on the horizontal horizontal plate 2;

[0025] The height adjustment assembly includes a servo motor 3, a driving gear 4 and a driven gear 5. The servo motor 3 is fixedly installed on the top of the support frame 1. The output end of the servo motor 3 is fixedly connected with the driving gear 4, the driving gear 4 and the horizontal horizontal plate 2. Rotationally connected, and one side of the driving gear 4...

Embodiment 2

[0035] Such as Figure 1-2 As shown, in the embodiment of the present invention, an automatic claw handling hand mechanism includes a support frame 1 and a base 22, the upper part of the base 22 is fixedly equipped with a support frame 1, and the top of the support frame 1 is fixedly equipped with a horizontal horizontal plate 2, The support frame 1 is provided with a lifting seat 7, and a clamping mechanism 15 for moving materials is installed on the lifting seat 7, and a height adjustment assembly for adjusting the height of the clamping mechanism 15 is also installed on the horizontal horizontal plate 2;

[0036] The height adjustment assembly includes a servo motor 3, a driving gear 4 and a driven gear 5. The servo motor 3 is fixedly installed on the top of the support frame 1. The output end of the servo motor 3 is fixedly connected with the driving gear 4, the driving gear 4 and the horizontal horizontal plate 2. Rotationally connected, and one side of the driving gear 4...

Embodiment 3

[0041] Such as Figure 1-2 As shown, in the embodiment of the present invention, an automatic claw handling hand mechanism includes a support frame 1 and a base 22, the upper part of the base 22 is fixedly equipped with a support frame 1, and the top of the support frame 1 is fixedly equipped with a horizontal horizontal plate 2, The support frame 1 is provided with a lifting seat 7, and a clamping mechanism 15 for moving materials is installed on the lifting seat 7, and a height adjustment assembly for adjusting the height of the clamping mechanism 15 is also installed on the horizontal horizontal plate 2;

[0042] When the height of the lifting seat 7 and the clamping mechanism 15 needs to be adjusted, the servo motor 3 is turned on, the servo motor 3 drives the driving gear 4 and the driven gear 5 to rotate, and the driven gear 5 drives the screw rod 6 to rotate, so that the screw rod 6 drives the inner threaded sleeve The cylinder 9 and the lifting seat 7 move up and down,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com