Novel plasticator capable of automatically overturning rubber

A technology of automatic turning and plasticizer, applied in the field of industrial machinery, can solve the problems of long time consumption, low efficiency, and inability to increase the processing efficiency of plasticizer, and achieve the effect of speeding up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

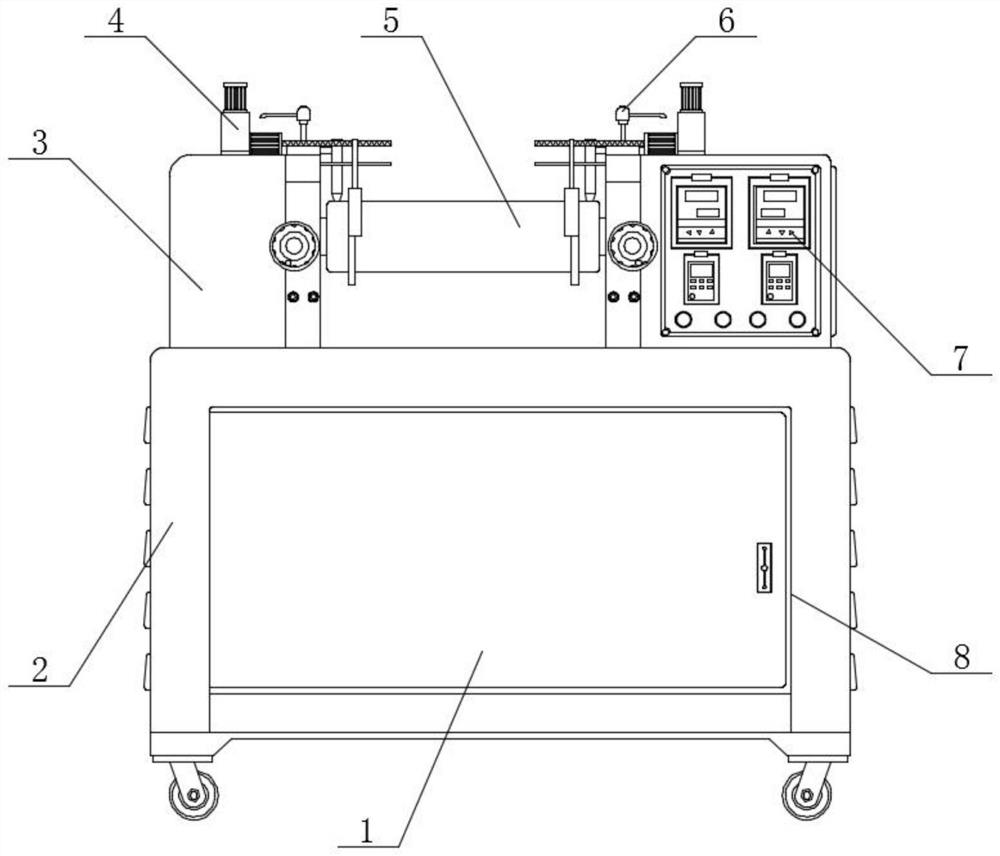

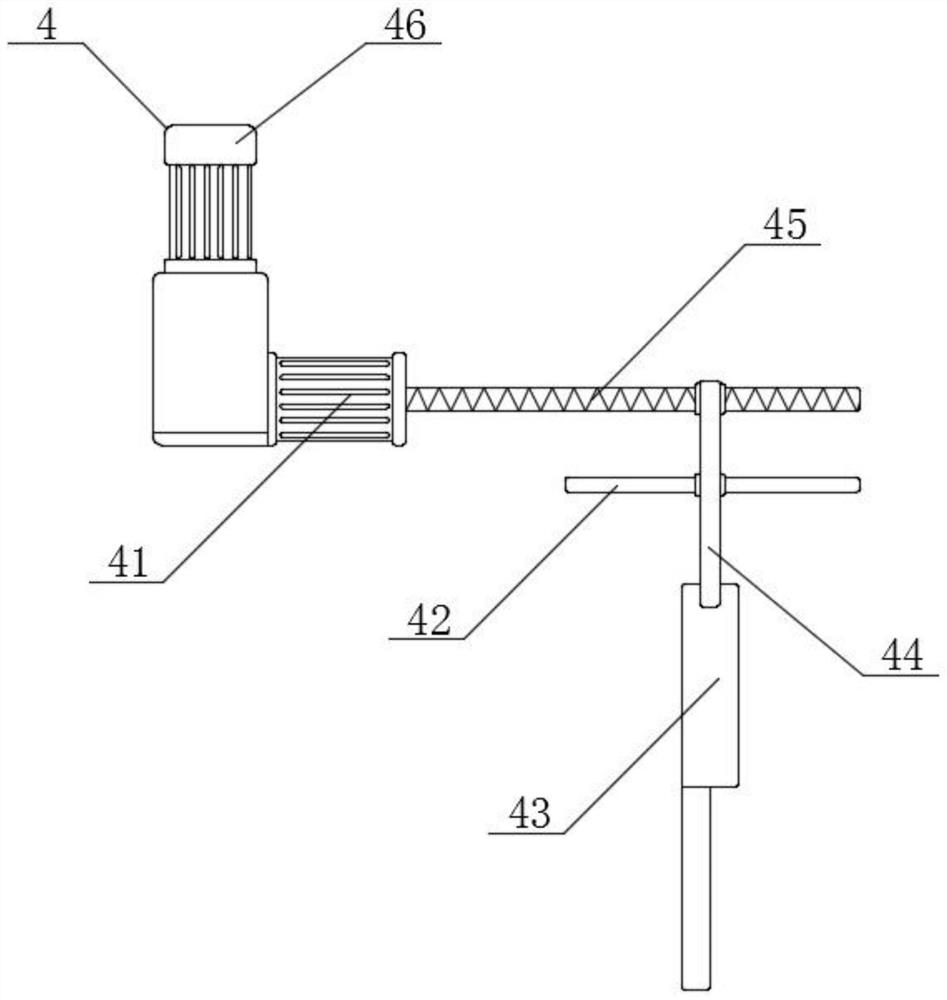

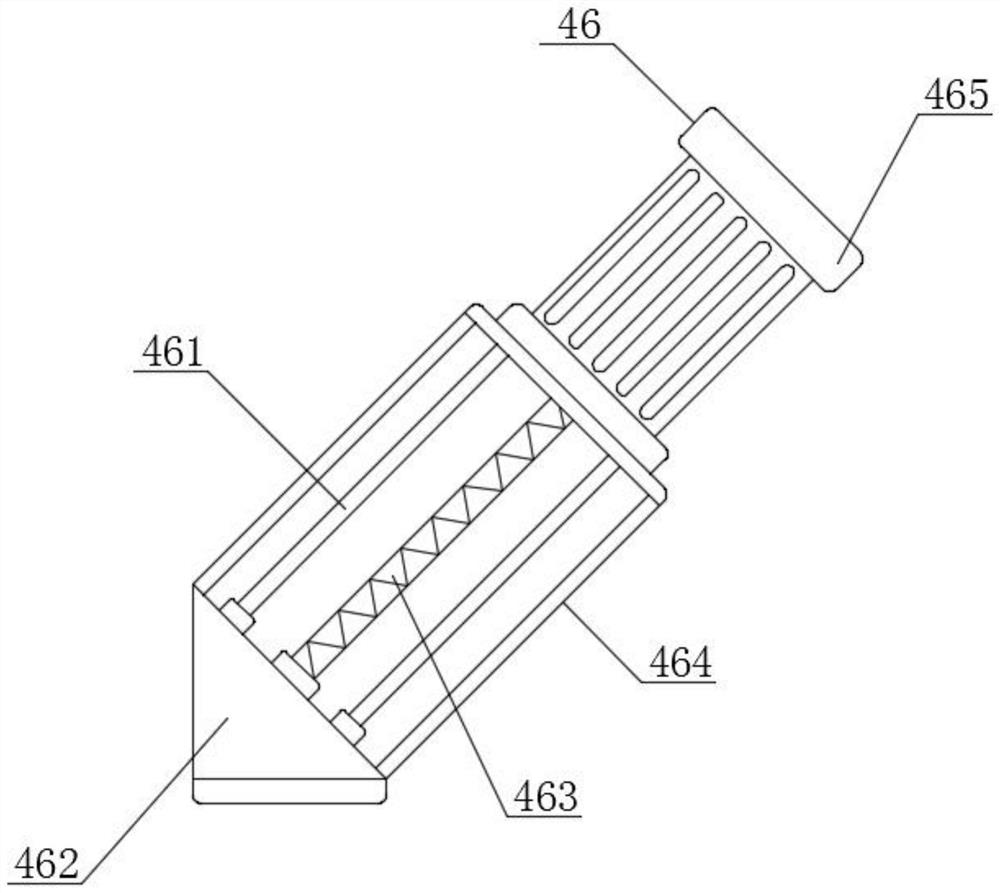

[0031] Such as figure 1 As shown, a new type of rubber plasticizer that can automatically turn over includes a support frame 2 and an electric control box 8. The front end surface of the support frame 2 is connected with an electric control box 8, and the inner surface of the electric control box 8 is connected by a hinge. Cabinet door 1, the upper end surface of the support frame 2 is connected with a transmission box 3, the middle of the transmission box 3 is connected with a roller 5, and the outer surface of the roller 5 is connected with a turning device 4 at the position of the upper end surface of the transmission box 3, and the turning device 4 The rear is connected with a brake lever 6 at the upper end face position of the transmission box 3, and the right side of the drum 5 is connected with a control panel 7 at the front end face position of the transmission box 3. The turning device 4 includes a horizontal motor 41, a limit lever 42, a turning Circle 43, drive rod ...

Embodiment 2

[0034] Such as Figure 1-4As shown, a new type of rubber plasticizer that can automatically turn over includes a support frame 2 and an electric control box 8. The front end surface of the support frame 2 is connected with an electric control box 8, and the inner surface of the electric control box 8 is connected by a hinge. Cabinet door 1, the upper end surface of the support frame 2 is connected with a transmission box 3, the middle of the transmission box 3 is connected with a roller 5, and the outer surface of the roller 5 is connected with a turning device 4 at the position of the upper end surface of the transmission box 3, and the turning device 4 The rear is connected with a brake lever 6 at the upper end face position of the transmission box 3, and the right side of the drum 5 is connected with a control panel 7 at the front end face position of the transmission box 3. The turning device 4 includes a horizontal motor 41, a limit lever 42, a turning Circle 43, drive ro...

Embodiment 3

[0037] Such as Figure 1-4 As shown, a new type of rubber plasticizer that can automatically turn over includes a support frame 2 and an electric control box 8. The front end surface of the support frame 2 is connected with an electric control box 8, and the inner surface of the electric control box 8 is connected by a hinge. Cabinet door 1, the upper end surface of the support frame 2 is connected with a transmission box 3, the middle of the transmission box 3 is connected with a roller 5, and the outer surface of the roller 5 is connected with a turning device 4 at the position of the upper end surface of the transmission box 3, and the turning device 4 The rear is connected with a brake lever 6 at the upper end face position of the transmission box 3, and the right side of the drum 5 is connected with a control panel 7 at the front end face position of the transmission box 3. The turning device 4 includes a horizontal motor 41, a limit lever 42, a turning Circle 43, drive r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com